20+ Years

Experience of die casting machine manufacturer

Die casting machine manufacturer in China

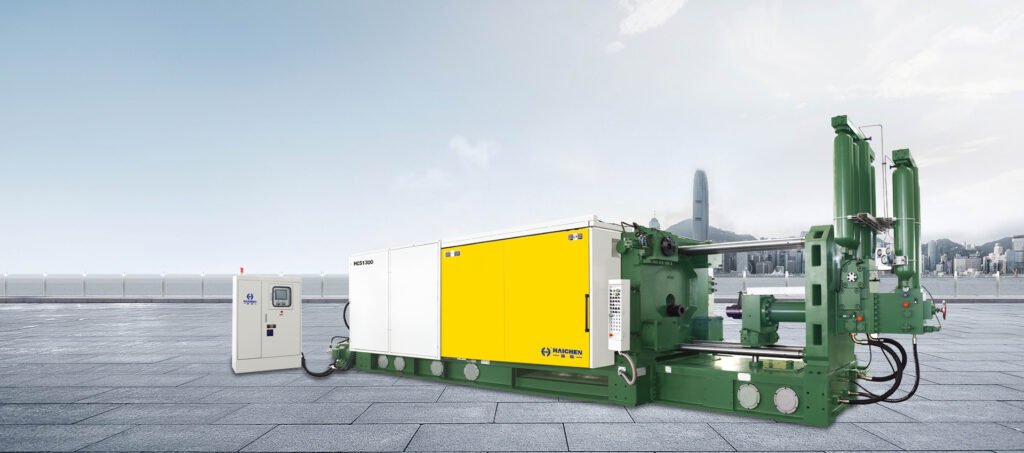

Haichen die casting machine manufacturer: high pressure die casting machines (HPDC), including hot chamber and cold chamber machines for Aluminum, Zinc, Lead, and magnesium. Manufacture Die-casting machines from 500 to 30000 kN tons with energy-saving systems and servo control hydraulic injection. Our die casting machine factory located in Ningbo China, is fully equipped to support sales, service, parts, customer training, research and development.

Haichen as a die casting machine manufacturer has manufactured the first High Pressure Die Casting machines to the overseas market since 2005. Our die casting machine with different operation languages, like English, Spanish, Russian, and Chinese… It makes us the most proven and reliable partner for your die casting machinery needs. Our three performances demanded of die casting machines: operational ease, fast cycle, and high-quality shots for thin wall and structural casting.

Haichen Hot Products

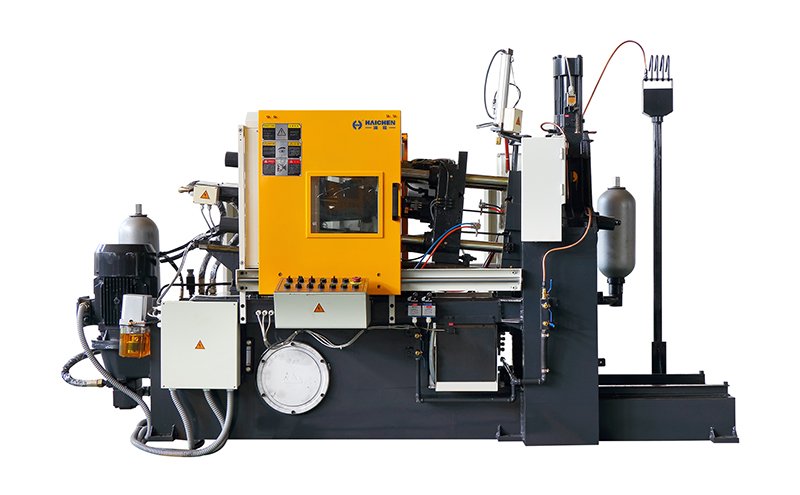

- Hot chamber die casting machine

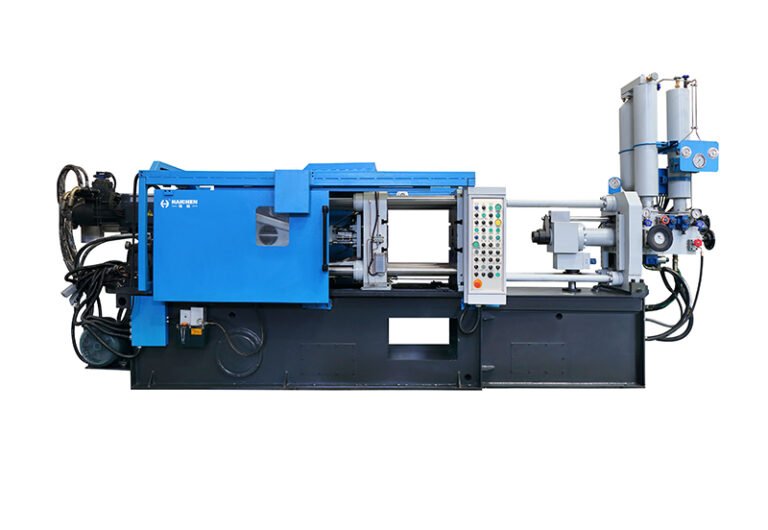

- Cold chamber die casting machine

- Auxiliary equipment for casting automatic

- Wear parts and spear parts for casting

Cold chamber die casting machine suit for Aluminum and magnesium casting. As the aluminum and magnesium melt temperature is higher than 700 degrees, so we have to keep the furnace separated from the casting machine. The chamber is kept outside of the furnace, keeping the lower temperature. That why we call this casting machine is cold chamber die casting machine.

Hot chamber die casting machine suit for Zinc part casting and Lead casting. As the Zinc and Lead melt temperature is lower, the furnace can be assembled on the machine. The chamber keeps inside of the furnace, keeping hot. That why we call this casting machine is hot chamber die casting machine.

As the manufacture of die casting machines, we’d like to share not just our machines, also our experience on the alloy die cating. We’d like to support the die casting solutions free!

Haichen is Your Die casting Partner

Haichen is an important manufacturer of die-casting machine equipment, specializing in providing die-casting production solutions for aluminum alloys, magnesium alloys, zinc alloys, and copper alloys. Our products cover solutions for large die casting islands. Haichen cooperate closely with customers to jointly promote innovation and development in the die-casting industry. We not only have advanced die casting processes, but also are committed to technological innovation, researching and developing technologies such as vacuum casting, extrusion casting, and intelligent production.

Haichen Factory

Haichen is located in Ningbo, Zhejiang, China. Haichen specialized in the production and sale of hot chamber die-casting machines, cold chamber die-casting machines, servo die casting machines, magnesium alloy die-casting machines, and relative auxiliary equipment.

Haichen manufactured two types of die casting machines: cold chamber die casting machines and hot chamber die casting machines.

Two types of die casting machines & The most widely used for die casting

Two basic types of die casting machines: hot-chamber die casting machines and cold-chamber die casting machines. Haichen produces both two types of die casting machines.

Clod chamber die casting machines use metals: aluminum magnesium and brass.

Hot chamber die casting machines use metals: Zinc and Lead.

Type 1: Cold chamber die casting machine- HCD Series

Aluminium pan and pot die cating

CE/ISO 9001

Melt the aluminum, inject it into the die-casting mold, and form it as the pot body. Die cast aluminum pots usually have thicker pot bodies, which make them evenly heated and less prone to deformation.

LED lamp housing field die cating

CE/ISO 9001

Die-casting technology is widely used to manufacture aluminum shells, which not only have high strength and durability but also provide good heat dissipation performance, which is crucial for the long-term stable operation of LED lamps

Radiator and building materials casting

CE/ISO 9001

The radiator adopts aluminum die-casting technology, which can achieve integrated molding, ensuring compact structure and uniform texture, thereby significantly improving heat conduction efficiency and lightweight

Auto Motorcycle Accessories die cating

CE/ISO 9001

Aluminum alloy die-casting technology has significant advantages in the manufacturing of automotive parts, with a wide range of applications, including components for traditional and new energy vehicles。

Type 2: Hot chamber die casting machine- HCH Series

Lock cylinder die casting

CE ISO 9001

Lock cylinder die casting is a precision machining process used to produce lock cores, typically using zinc alloy as the material. Die casting technology can produce lock cylinder parts that are lightweight, tough, and highly resilient

Door handle die casting

CE ISO 9001

Door handle die-casting is a metal die-casting process, which mainly involves rapidly filling the mold cavity with molten metal under high pressure and solidifying it under high pressure to form a metal die-casting part。

Zinc pipe fitting die casting

CE ISO 9001

Galvanized pipe joints are usually made of zinc alloy material by die casting, and then surface treatment processes such as galvanizing or nickel plating are used to improve their corrosion resistance and appearance quality

Hot chamber used for Zinc and Lead die casting

Why Do Business With Us?!

- 20 years of experience selling die casting machines, equipment and manufacture worldwide.

- We manufacture Cold Chamber Aluminum, Magnesium, and Brass die casting machines; Hot Chamber Zinc and Lead die casting machines.

- The machines including Hydraulic, Servo-energy saving, Servo valve controlled injection, All real-time control system…

- We purchase quality spear parts of die casting machines world wide.

- We choose an international brand of spear parts, with a famous brand, so that our user can find some spear parts near their factory.

- The machines’ valves, controllers, and hydraulic parts are easy to find at the local market.

- We supply auxiliary device of die casting machines.

- We buy and sell all items used in the die-casting process including furnaces, x-ray machines, spectrometers, shot blasts, and vibratory finishing equipment.

- We also supply die casting automation: automatic ladles, die sprayers, extractors, and robots.

- Our services to our customers include:

- We share the solution for all kinds of die casting.

- We are a manufacture company of die casting machine, help you find the right machine for your application and budget.

Enterprise core competence

R&D Capability

ODM service: YES

OEM service: YES

Cetification

ISO9001: YES

CE Certification: YES

Trade Capability

Over 18 years

experience for export

Production Capability

Output value: 30 sets

15-45 days for Delivery

Haichen die casting machine manufacturer FAQ guide

Looking for the manufacture of die casting machine? Need an ideal solution for die-casting production of your metal products? Look no further than an Aluminum Die Casting production line Supplier. With over a decade of experience, Haichen die casting machine manufacture in China excels in aluminum die casting, Zinc die casting, Lead casting, and Magnesium casting, offering fast and reliable solutions for your die casting project needs.

Q: Can you design my parts and execute mold flow analysis for aluminum die casting production?

A: Yes, we have experienced designers and the necessary hardware required to design parts for you. Additionally, we can conduct effective simulations for mold flow analysis in advance. Our talented engineers can design your parts with a high degree of accuracy and optimize them for easier production, cutting down on costs.

Q: Can Haichen provide a complete die casting solution for production, with the list of types of equipment?

A: Yes, Haichen likes to offer fast solutions for any of your die casting projects with the list of die casting machines, die casting mold, landel, sprayers, extractors…

Q: How does Haichen machine control the quality of the production process?

A: Haichen die casting, as professional die casting machine manufacturer, we maintains a superior quality management system certified by ISO 9001, CE standards. Haichen comply with relevant national and industry standards, such as GB/T 21269-2023 “Cold Chamber Die Casting Machine” standard, to ensure that the die casting machine meets technical requirements and quality assurance standards

Q: Is Haichen machine a continually improved company?

A: Yes, Haichen company is committed to continuous improvement. By continuously innovating technology and investing in research and development, we aim to enhance the practicality and reliability of die-casting machines. Haichen die-casting machine is developing towards automation and intelligence. This not only improves production efficiency but also enhances casting product quality.

Q: What is Haichen die casting machine market?

A: Haichen die casting machine market including India, Russia, Mexico, China…Especially in the automotive industry die castingMexico, the demand for integrated die-casting technology is growing rapidly.