Cold Chamber Die Casting Process

Cold Chamber Die Casting is a precision casting process for high melting point metals such as aluminium, copper and brass. Its main features and steps are as follows: Cold chamber die casting mould preparation First of all, it is necessary to design and manufacture the mould (also known as tooling or mould), which usually consists […]

Difference between hot chamber and cold chamber die casting

Difference between hot chamber and cold chamber die casting includes equipment structure, material suitability, production efficiency and so on. Hot chamber die casting and cold chamber die casting are two common die casting processes, which have significant differences in equipment structure, material applicability, production efficiency and safety. In this blog, we will analyse the difference […]

Cold Chamber Die Casting Advantages

Cold Chamber Die Casting Advantages include high precision, complex shapes, wide alloy range, high efficiency, and energy savings. Cold chamber die casting stands out as a unique approach for crafting intricate and sizable metal parts, especially in industries where immense precision and detail are pivotal. Unlike hot chamber die casting, this approach has its own […]

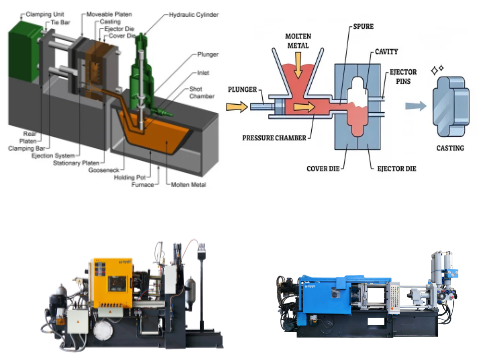

What is a cold chamber die casting machine

Cold Chamber Die Casting Machine is a type of equipment used for metal die casting, mainly for the production of high-precision, dimensionally consistent parts. This machine is particularly suitable for metals with high melting points, such as aluminum, copper and brass. Working Principle of Cold Chamber Die Casting Machine Chamber die casting is a form of die […]