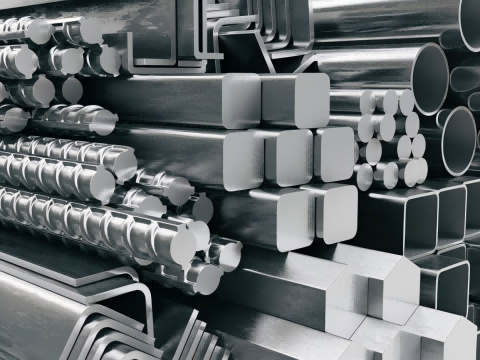

Types of Aluminum materials

Types of Aluminum materials: Aluminum alloy is a metallic material formed by adding one or more alloying elements such as copper, magnesium, silicon, zinc, manganese, etc. to aluminum (Al) as the base element. As the most widely used non-ferrous metal structural material in industry, its usage volume is second only to steel. It features light […]

Difference between aluminium and aluminium alloys

Difference between aluminum and aluminum alloys reflect in composition, performance comparison, applications and etc., Aluminum is a lightweight, corrosion-resistant pure metal suitable for general use. While aluminum alloys are suitable for more demanding application scenarios by adding other metal elements that significantly increase strength, hardness and corrosion resistance. As metals go, aluminum is light and […]

Different Grades of Aluminum and Applications

Different Grades of Aluminum and Applications mainly include 6061, 7075, 2024 they use in aerospace, automobile manufacturing and others. There are many different grades of aluminum, including 6061, 7075, 2024, 3003, 1100, 2011, and 5005. The grade of aluminum you choose depends on the project’s requirements, such as strength, corrosion resistance, and cost. In this blog, we […]

What is the Highest Strength Aluminum Alloy?

Aluminum alloy broadly used in the die casting sectors of aerospace, automotive, and construction for their light weight and great strength-to-weight ratio. Among these, the 7xxx series (Al-Zn-Mg-Cu) alloys are known to be very strong and indeed they are the best among all aluminum alloys. A detailed overview of the highest strength aluminum alloys, their properties, and […]

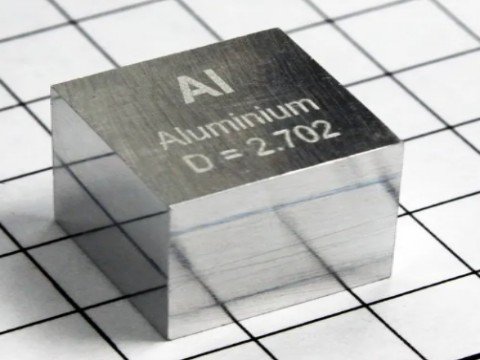

Density of Aluminum & Aluminum Alloys

The Density of Aluminum & Aluminum Alloys is key for applications. Pure aluminum and common alloys have densities around 2.7 g/cm³. Aluminum ranks among the most plentiful metallic elements residing in the earth’s crust, and its promise of low density, resistance to corrosion, and superb manufacturability has secured its place across sectors like aerospace, automotive, […]

Is cast aluminum cookware safe?

Cast aluminum cookware is widely used in kitchens due to its excellent heat conductivity, lightweight nature, and durability. However, concerns about its safety often arise, particularly regarding potential health risks. Below is a detailed analysis of the safety of cast aluminum pots, addressing common questions and misconceptions. Answers to the safety of aluminum alloy die-cast […]

Maintenance Method of Die Casting Mold

Die Casting Mold maintenance methods require a combination of measures to ensure their life and performance. The quality, cost and overall output of die-cast products are intrinsically linked to the quality of injection moulds and the timeliness of their maintenance. Consequently, daily mould maintenance practices are of paramount importance. The maintenance and upkeep of die-casting […]

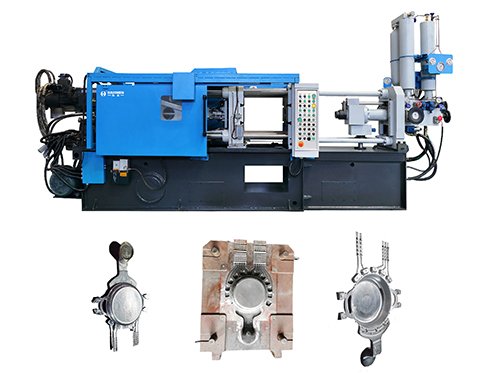

Types of Die Casting Moulds

Die-casting moulds (dies) are defined as those special tools which shape molten metal into components under high pressure with very close tolerances assumed as the most common definition of die castings. The type of mold selected will depend upon such factors as production volume, part complexity, material to be used, and cost requirements. Below is […]

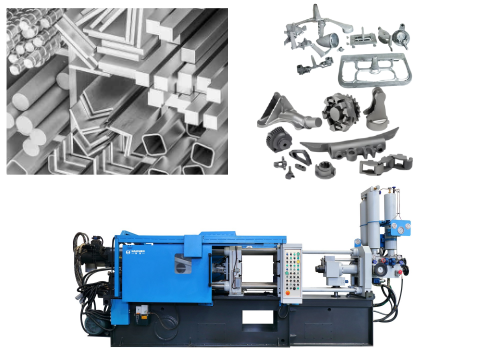

Cast Aluminum Applications

Cast Aluminum is widely using in many industries due to its light weight, high strength, corrosion resistance so it’s good casting performance. Cast aluminium is renowned for its outstanding properties, making it a favoured choice within the aluminium casting sector. It possesses high strength, exceptional durability and corrosion resistance – all essential characteristics for premium […]

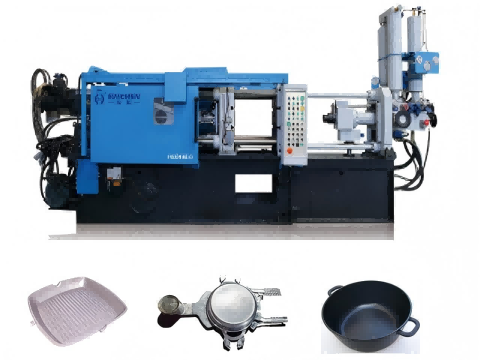

What is die casting cookware?

Die casting cookware refers to kitchen utensils, such as pots, pans, and other cooking vessels, that are manufactured using the die casting process. Cookware is using cold chamber die casting machine for production. Die casting is a manufacturing technique that involves forcing molten metal under high pressure into a mold cavity. The mold cavity is […]