How do we check the quality of an aluminium die casting?

To ensure the quality of an aluminium die casting, a comprehensive approach involving multiple inspection techniques and adherence to industry standards is essential. The quality control process for aluminum die castings begins with raw material inspection. Aluminum alloys undergo comprehensive testing to ensure they meet specific standards for chemical composition, strength, heat resistance, and durability. […]

How to avoid shrinkage voids in aluminium casts?

Avoid aluminium casts shrinkage voids includes optimize the design, control and control the cooling process and so on. To avoid shrinkage voids in aluminum castings, please see below following measures: 1. Avoid aluminium casts shrinkage voids: Optimize the design Avoid thick-walled areas: Thick-walled areas are more prone to shrinkage, which can form internal voids. Designers […]

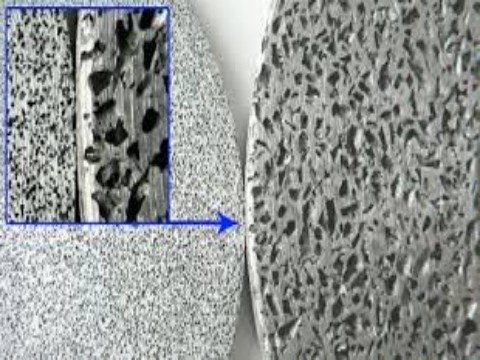

How to control porosity in pressure die casting

Controlling porosity in pressure die casting involves optimizing injection speed and pressure, ensuring proper mold venting, maintaining consistent metal temperature, and using high-quality alloys to minimize defects and improve part integrity. Pressure die casting is a highly efficient manufacturing process widely used in various industries to produce complex metal parts with high precision and dimensional […]

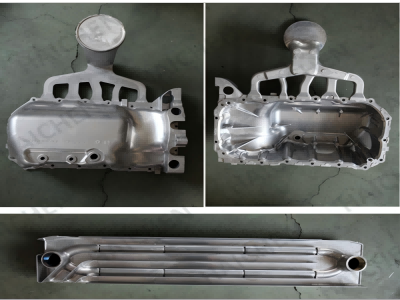

Tooling Material, Process and Failure Analysis in Die casting

While diecast tooling suffers from wear and fatigue, erosion or washout is the main failure mode of tooling in aluminum diecasting. Aluminum has relatively high chemical reactivity and solubility in iron. While in contact with iron, molten aluminum atoms diffuse into the iron matrix and form intermetallic compounds, such as Fe2Al5. These intermetallic phases melt […]

What causes crankshaft damage of die casting machine

Crankshaft damage in a die casting machine can result from several factors, often related to mechanical stress, improper maintenance, or operational issues. Here are the primary causes. Crankshaft damage causes of die casting machine Fatigue Failure Improper Lubrication Overloading Misalignment Material Defects Corrosion or Contamination Improper Maintenance Vibration and Resonance Improper Installation Thermal Stress Foreign Object […]