Why cause blisters in die casting?

Blisters in die casting are surface defects that manifest as bulging or raised bubbles on the surface of the casting, usually caused by the expansion of trapped gas inside. Air bubbles not only affect the appearance but can also damage the mechanical properties and airtightness of the casting, especially in subsequent processes such as electroplating […]

How to solve deformation during die casting

To solve deformation during die casting by optimize design, control process parameters, balance cooling, and reasonable ejection can reduce it significantly. To solve deformation during die casting process need start from many aspects. Including optimizing mold design, adjusting process parameters and improving material treatment. Optimize Mold Design Uniform Wall Thickness Ensure the mold design has […]

Detailed common faults and analysis of die casting machine

Common faults in die casting machines can hinder part quality. This article details these issues and provides practical solutions. Die casting machines are essential in modern manufacturing, especially for producing high-precision metal parts. However, like any machinery, they can encounter various faults that may affect production efficiency and part quality. Understanding these common faults and […]

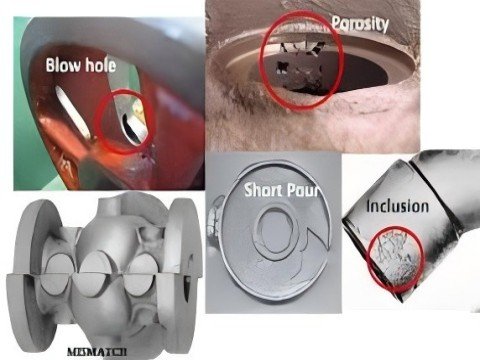

What are the failure modes of die casting?

Die casting is a high-pressure manufacturing process that involves injecting molten metal into steel molds. While efficient, the process is susceptible to several failure modes that impact tool life, product quality, and operational costs. Die casting involves injecting molten metal into a mold cavity under immense pressure. This method is particularly suitable for the rapid […]

Why does metal splash sometimes occur during die casting?

Metal splash occur during die casting includes: insufficient mold clamping force, injection pressure is too high or injection speed is too fast and so on. Metal splash, or the violent expulsion of molten metal from the die, is a serious safety and quality hazard in die casting. It occurs when high-pressure molten metal escapes through […]

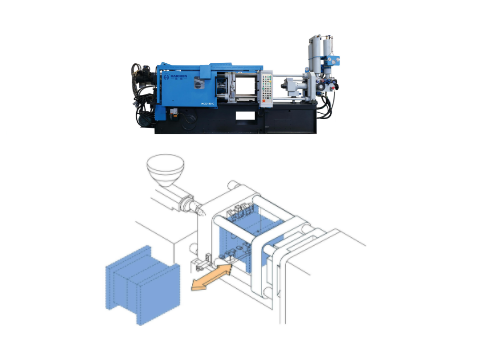

Application of Quick Die Change Systems for Die Casting machine

Quick Die Change Systems enables the automation of the mold-changing process, significantly enhancing the production speed, efficiency and productivity of the workshop. A quick die change system is an automated or semi-automated system. Designed to reduce the time required for die casting machines to change molds, improving production efficiency, safety, and flexibility. These systems typically […]