How do you reduce porosity in die casting

To reduce porosity in die casting through the systematic integration of process parameter optimization, mold venting design, vacuum/degassing technology, and numerical simulation. Reducing porosity in die casting is crucial for improving the mechanical properties and surface finish of the final product. Through the systematic integration of process parameter optimization, mold venting design, vacuum/degassing technology, and […]

Gas Porosity in die casting

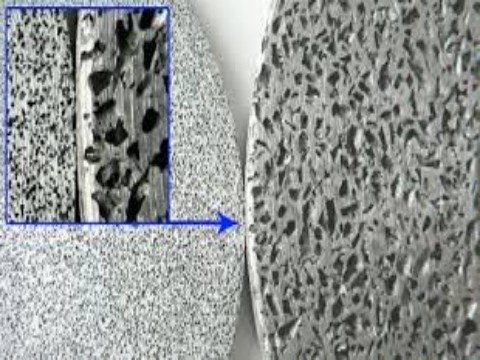

Gas Porosity refers to the bubbles or holes formed when the gas in the molten metal does not completely escape and solidifies during the die casting process. Gas Porosity Morphology Usually round or oval in shape, with a smooth surface and a diameter ranging from microns to millimeters. Distribution Due to the buoyancy of gases, […]

Shrinkage porosity in die casting

Shrinkage defects are those cavities inside the parts that reduce strength; if they are on the surface, they reduce aesthetics and corrosion resistance. It is also very important to be able to differentiate between shrinkage cavities and gas bubbles: cavities from gas bubbles are always round, whereas shrinkage cavities due to lack of material have […]

What Causes Porosity in die casting

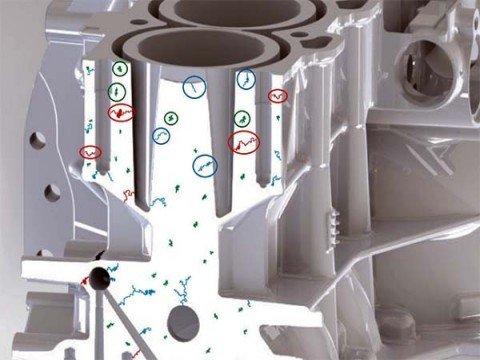

Porosity in die casting is primarily caused by trapped air or gas within the mold cavity, improper gating and venting designs, insufficient compaction of the molten metal, and variations in the injection process such as speed and pressure. Die casting is a highly efficient manufacturing process used to produce complex metal parts with tight tolerances. […]

How to Prevent Porosity in Aluminum Die Casting?

Prevent porosity in die casting includes optimize mold design, control pouring parameters, refining and degassing, and so on. Preventing the formation of pores in aluminum alloy die castings is an important measure to improve product quality and performance. 1. Prevent porosity in die casting: optimize mold design Mold design is a key step in reducing […]