Manufacturer of Plunger Tips for Die Casting Machines

Manufacturer of Plunger Tips for Die Casting Machines: Plunger tips also known as the plunger head of the die casting machine is the core component of the die casting process. And plunger tips design, materials and maintenance directly affect the casting accuracy, production efficiency and equipment life. The plunger head is a critical component in […]

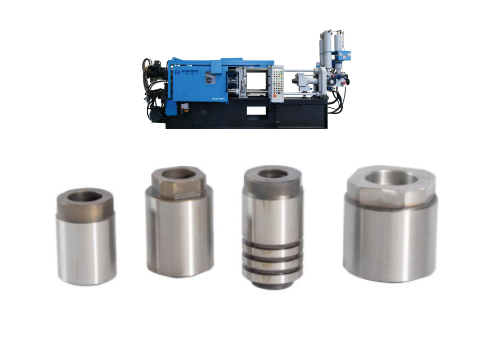

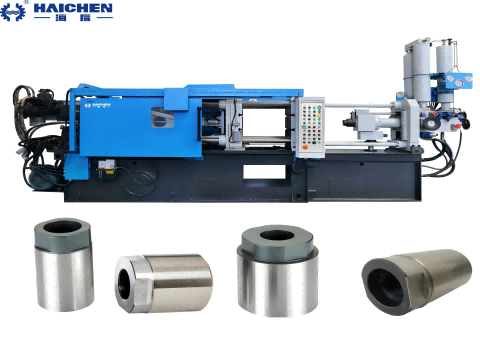

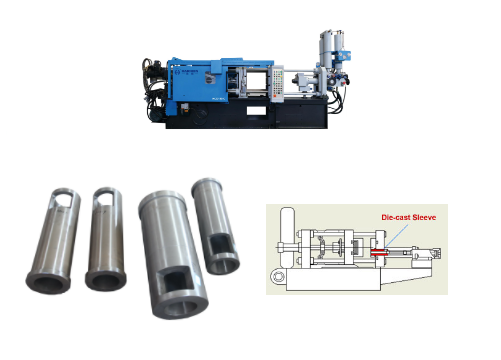

High-Pressure Die Casting plunger tips

Plunger Tips are the end part and most critical element of the shot end assembly. Its role is to contact the molten metal and force it through the sleeve and into the die cavities. It’s also a part of the injection system in a die casting machine, and it plays a vital role in ensuring […]

Key factors in selecting Die Casting Plunger Tips

When selecting die casting plunger tips, key factors include material compatibility with the molten metal, tip geometry for optimal flow and pressure control, durability to withstand high – pressure injection, and ease of maintenance and replacement to ensure consistent performance and minimize downtime. Die casting is a precision manufacturing process that requires careful attention to […]

Types of Plunger Tips for Die Casting

Plunger tips for die casting are component utilised within the injection sleeve of a die-casting machine. It is designed to regulate the flow of molten metal into the injection sleeve, ensuring precise casting production and minimising defects. These are typically custom-engineered for specific die-casting machine models and come in various shapes and sizes to accommodate […]

Plunger Tip for Die Casting

Plunger Tip for Die Casting includes its function, material selection, customization and maintenance, design and optimization and so on. The plunger tip is a critical component of the die-casting machine’s shot-jetting system. Its design must balance cooling efficiency, material strength, lubrication and sealing, and geometric matching. Selecting high-thermal-conductivity materials, optimizing water flow design, and employing appropriate lubricants. […]

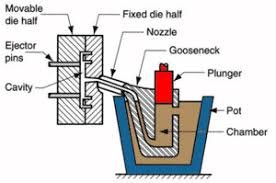

Why Choose Haichen for Gooseneck Repair

Haichen Machinery is a professional die casting machine gooseneck pot producer. In hot chamber die casting machines, gooseneck pots (or goosenecks) are the key components connecting the furnace and the mold. Responsible for transporting the molten metal from the furnace to the mold. And its design directly affects the quality, production efficiency and equipment life […]