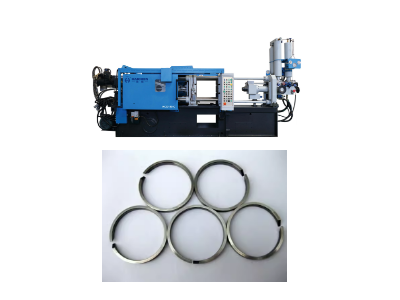

Plunger Rings for Die Casting Machines

Plunger Rings also known as the injection sleeve or pressure ring is one of the core components of the injection system of the die-casting machine. It mainly transmits pressure, seals the molten metal flow channel, and withstands mechanical and thermal shock in high-temperature, high-pressure environments. As a leading manufacturer of shot end components for die […]

Application of Plunger Ring for die casting

Die casting plunger ring application includes improve production efficiency and product quality, reduce defects, etc. The plunger ring used in the die casting process is an important part of the die casting mold. Its main function is to ensure the accuracy and efficiency of the die casting process. The plunger ring usually installes on the […]

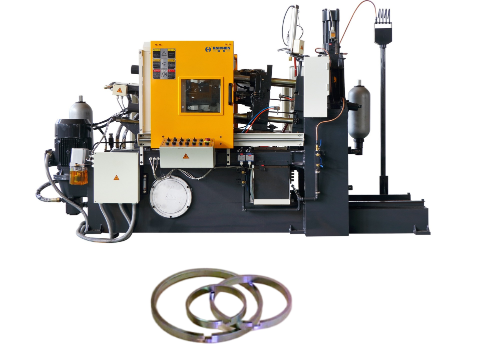

Plunger Rings Design & Manufacture

Plunger rings play a critical role in the efficient operation of various mechanical systems, particularly in hydraulic and pneumatic applications. Plunger Rings Design Manufacturers produce them using advanced materials and precision techniques to meet the demanding requirements of modern industries. Material Selection Manufacturers select high-performance materials like ASL42 stainless steel or tool steel for them […]

Materials of Plunger Ring for die casting

Plunger rings (also known as plunger tips or plunger heads) are critical components in die casting machines, responsible for sealing the shot sleeve and ensuring precise injection of molten metal into the mold. Their material must withstand extreme temperatures, high pressure, and abrasive wear. The plunger ring is a key component in the die casting process. Their successful […]

Common Issues of Plunger Ring for die casting

Plunger Ring Issues in Die Casting include wear and tear, thermal fatigue, and material buildup, which can lead to reduced sealing efficiency, increased metal leakage, and inconsistent shot volumes. In die casting production, the pusher ring is directly related to whether the molten metal can be smoothly injected into the mold cavity. This component needs […]