Disadvantages of Die Casting Overflow

Disadvantages of Die Casting Overflow include material and resource waste, impurity recovery issues, negative impact on mold life. Product quality defects are also disadvantages of die casting overflow. Die casting overflow grooves play an important role in improving casting quality. Exhaust and thermal balance, there are many shortcomings in their design and application. Waste of […]

What Does Die Casting Overflow Do?

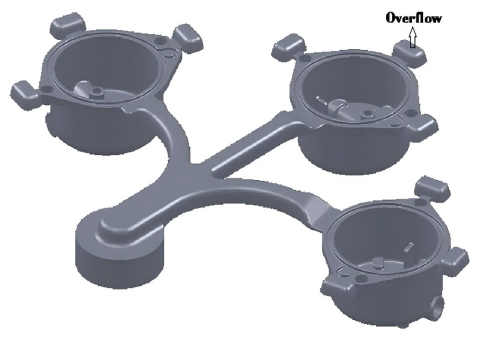

Die casting overflow do includes vent and reduce oxidation, control molten metal flow, maintain mold temperature uniformity etc. The overflow port of the die casting machine is a precisely designed auxiliary cavity system in the mold. Its core functions are exhaust, slag collection, flow control and heat preservation, which directly determines the integrity of the […]

Solution of Die Casting Overflow

Addressing die casting overflow involves optimizing mold design to ensure proper venting, adjusting injection speed and pressure to prevent excess material flow, and maintaining consistent cooling to solidify the metal quickly and evenly. Die casting overflow, or flash, occurs in the die casting operation when excess molten metal spills out of the mold cavity, turning […]

What is Die Casting Overflow

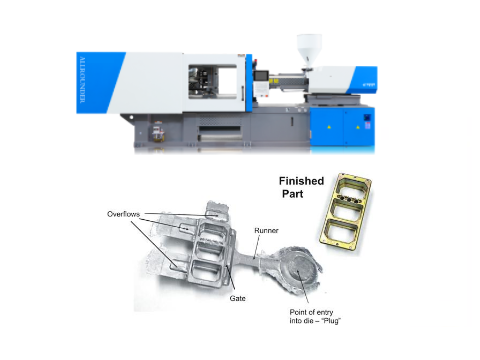

Die Casting Overflow is a small chamber in molds that collects excess molten metal to ensure consistent casting quality. Die casting is a precision manufacturing process used to produce complex metal parts by injecting molten metal into a mold cavity under high pressure. One common feature in die casting molds is the overflow, which plays […]

Design Tips of Die Casting Overflow

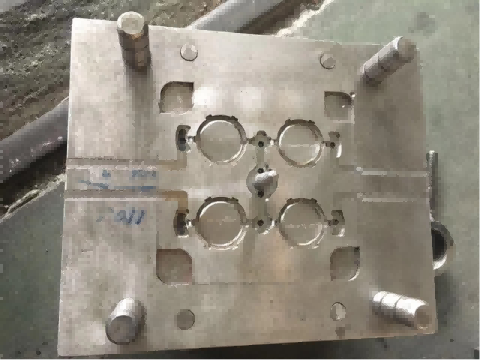

Die Casting Overflow design necessitates the management of flow dynamics, heat regulation, and ease of manufacture. Validate configurations with the help of modeling software, employ conventional forms, and involve foundries from the start for continuous improvement. Well-designed overflow systems can decrease fault rates (such as porosity and cold shuts) by approximately 30% in high-pressure die […]