Key parameters for servo motor selection in die casting

Key parameters select servo motor in die casting includes power, torque, precision, speed,control mode and so on. While choosing a servo motor for a die casting machine, there are many factors that need consider such as: load inertia, effective torque, speed ratio and precision. Also with electrical parameters, a built-in braking function, communication ports, servo […]

Servo motor vs traditional hydraulic system comparison in die casting

Die casting is a crucial process in manufacturing, and the choice of drive system—whether servo motor or traditional hydraulic—can significantly impact efficiency, precision, and overall production. Servo motor vs traditional hydraulic system comparison Here’s a detailed comparison of servo motors and traditional hydraulic systems in die casting applications. Energy Efficiency of Servo motor Servo motors […]

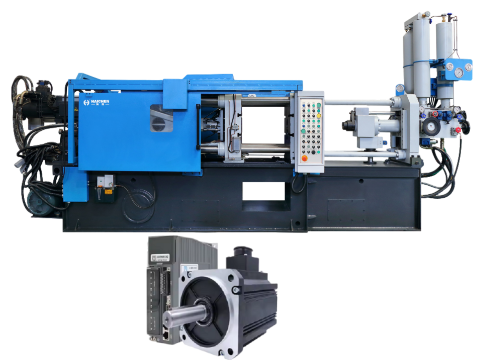

Components of servo motor in die casting

A servo motor in die casting is basically an electric motor that offers very fine control over motion at a certain position, over speed, and torque. Major parts include a rotor-the moving part inside the machine; stator- as the stationery part outside the moving component; encoder, or resolver- these devices provide information regarding where exactly […]

Faults and Solutions servo motor in die casting

Common faults and Solutions servo motor in die casting are overheating, encoder errors, and mechanical wear, which can be resolved through proper cooling, calibration, and regular maintenance for reliable operation. Precision and efficiency in die casting machines are achieve through the use of servo motors. They manage multiple processes, such as mold clamping and injection […]

Casting process and alloy matching

The matching of casting processes with alloys is a complex task that requires balancing material properties, process requirements, economic factors, and application scenarios. Alloy casting is the process of melting multiple metals (and occasionally non-metallic materials) into a mould. Upon cooling and solidification, the alloy casting assumes the shape of the mould used, producing components […]

Stainless Steel Alloy Casting Services

Stainless steel alloy casting services are typically used for the production of die-casting molds. It performs well in liquid environments and provides heat resistance at high temperatures. There are numerous types of stainless steel and each contains a different chemical composition. The composition affects mechanical properties and determines whether the material can be further strengthened […]