Zinc Die Casting Services

Zinc die casting services includes optimize zinc alloy compsition and performace, mold design, surface treatment, production problems solutions, etc. What is zinc alloy? Zinc alloy is zinc alloy materials made by adding other metals. (Such as aluminum, copper, magnesium, nickel, tin, etc.) to zinc as the base metal through smelting or die casting processes. By […]

Zinc Die Casting vs. Aluminum Die Casting

Zinc Die Casting vs. Aluminum Die Casting,covering: Zinc die casting has advantages in precision, surface quality and economic efficiency in mass production, While aluminum die casting dominates specific fields with its lightweight, high-temperature resistance and high specific strength. The specific performance comparison between zinc die casting and aluminum die casting in lightweight applications mainly lies […]

Is zinc good for die casting?

Zinc is highly suitable for die casting due to its exceptional properties and process advantages, as supported by extensive evidence. Zinc alloy die casting is very popular in the manufacturing of parts for the construction and industrial sectors, but its most common application is still in the automotive industry. In fact, many parts in cars […]

Zinc die casting process

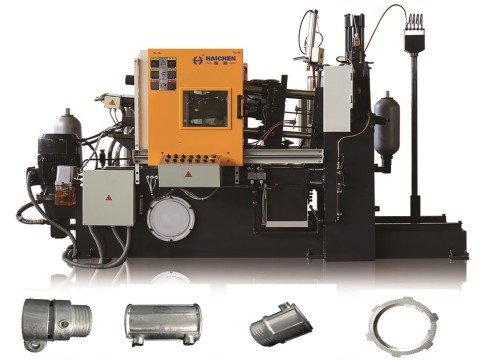

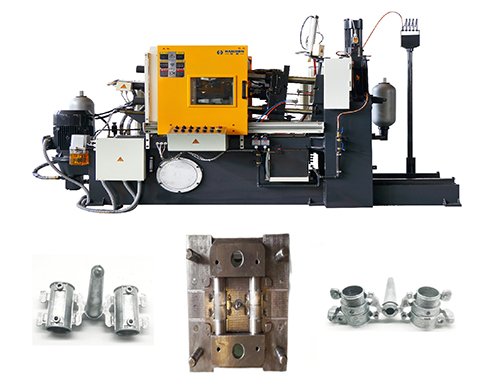

Zinc die casting is an efficient and precise metal manufacturing process that is widely used to produce complex and precision metal components. Zinc die casting process Its main features and processes are as follows: Melting and Control of Zinc Alloy Zinc alloy is typically heated to its melting temperature of 380 to 480°C (776 to […]

What is zinc die casting used for?

Components used in the automotive, aerospace, consumer electronics, and hardware industries require high-precision thin wall metals. Zinc die casting is used to manufacture these parts because it has the capability of making complex parts with high accuracy. As with all die casting methods, zinc die casting is a multistep process that combines the steps of […]