There are two primary main types of die casting machines:

- Cold chamber die casting machine

- Hot chamber die casting machine.

Hot chamber die casting machine: The casting chamber and casting head are immersed in molten metal liquid, which is suitable for die casting of low melting point alloys such as zinc and lead.

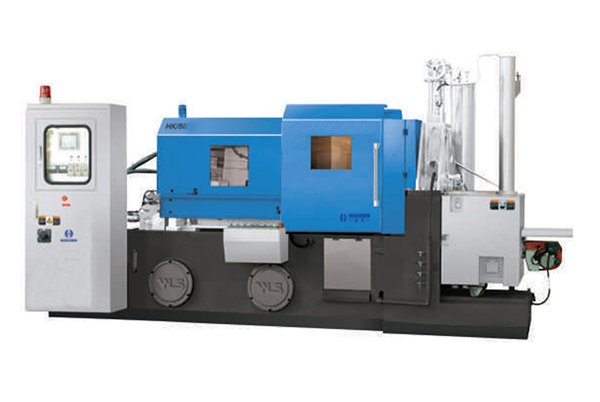

Cold chamber die casting machine: The casting chamber and casting head are not immersed in the molten metal liquid, which is suitable for die casting of high melting point alloys such as copper, aluminum, and magnesium.

What are the different types of die casting machines?

Die casting machines can be divided into many types according to different classification standards.

There are two primary types of die casting processes, commonly hot chamber die casting and cold chamber die casting.

Die casting machines can be divided into many types according to different classification standards.

Types of scope of use for die casting machine

According to the Types of scope of use for die casting machine, die casting machines can be divided into General die casting machine and Special die casting machine.

General die casting machine: an industrial device used to produce metal parts by injecting molten metal into a mold (called a die) under high pressure.

General die casting machine is widely used in the manufacturing industry to produce complex metal parts with high precision and consistency.

Special die casting machine: a die casting machine that is specially designed to produce a specific type or shape of castings.

This type of die casting machine usually has highly customized functions and structures to meet specific production needs. In addition, Aluminum Alloy dedicated die casting machines are also favored for their real-time feedback control, automatic tuning function, and self-diagnosis functions, which help improve production efficiency and reduce maintenance costs.

Types by clamping force for die casting machine

Types by clamping force for die casting machine, die casting machines can be divided into small die casting machine, medium-sized die casting machines, Large die-casting machines.

Small die-casting machines refer to die-casting machines with a clamping force of less than 4000 KN, which are usually used to produce smaller parts.

Small die casting machines are widely used in many industries, including 3C manufacturing, the motorcycle industry, toy hardware, and kitchen hardware. The main application scenarios of small die casting machines are concentrated in areas that require smaller clamping forces, so their application range is very wide.

Medium-sized die casting machines are equipment used to produce medium-sized castings, usually with a clamping force of 400 to 1,000 tons.

This type of die casting machine is widely used in the fields of automobiles, motorcycle accessories, electronic equipment, etc., especially in the manufacture of non-structural parts such as engine parts, transmission housings, and wheels.

Large die-casting machines with a clamping force of more than 10,000 KN are mainly used to produce large and complex metal parts.

Types by machine structure, injection chamber location and working conditions

Types by machine structure, injection chamber location and working conditions, die casting machines can be divided into hot chamber die casting machine and cold chamber die casting machine.

Hot chamber die-casting chamber: The die chamber of this type of die casting machine is immersed in molten metal, usually with an automatic pouring system, which can directly introduce the metal liquid from the holding furnace into the injection chamber for die casting.

Hot chamber die-casting machines are mainly used for the processing of low melting point metals such as zinc alloys and magnesium alloys.

Cold chamber die casting machine: The die chamber of this type of die casting machine is separated from the molten metal holding furnace and does not have an automatic pouring system.

Cold chamber die casting machine usually requires manual or mechanical pouring of molten metal into the injection chamber for die casting. Due to the high melting point of metals such as aluminum alloys, cold chamber die casting machines are more suitable for processing these materials.

Types by clamping force for die casting machine by pressure chamber layout for die casting machine

Types by pressure chamber layout, die casting machines can be divided into Horizontal die casting machine and Vertical die casting machine.

Horizontal die casting machine: The die casting chamber is located in the horizontal direction of the machine.

The working principle of the horizontal die-casting machine is to inject the molten metal into the horizontal pressure chamber through the pouring hole, and then the injection punch is pushed forward to press the metal liquid into the mold cavity through the runner, and then cool and solidify into shape.

Vertical die casting machine: including the full vertical die casting machine, the die casting chamber is located in the vertical direction of the machine.

This vertical arrangement also allows the mold to be placed horizontally, making it easier to place the insert.

Types by the degree of automation for die casting machine

Types by degree of automation for die casting machine, die casting machines can be divided into Semi-automatic die-casting machine and Fully automatic die-casting machine.

Semi-automatic die-casting machine: is a multifunctional equipment that can switch between manual, semi-automatic, and fully automatic.

Fully automatic die-casting machine: is a highly automated and intelligent equipment that can significantly improve production efficiency and product quality.

Types by drive technology: for die casting machine

Types by drive technology, die casting machine can be divided into servo die-casting machine and Standard die casting machines.

Servo die casting machine: The servo die-casting machine uses servo drive, servo motor and quantitative pump as the power source system, replacing the traditional asynchronous motor and quantitative pump.

Standard die casting machines usually use traditional hydraulic or pneumatic systems as power sources, which may not be as good as servo systems in terms of response speed and energy efficiency.

Types by frame structure

Types by frame structure, die casting machine can be divided into C-frame die-casting machine and Right-angle side frame die-casting machine

C-frame die-casting machine: is a device used for metal casting, which is characterized by using a C-frame structure to connect the injection system and the fixed platen.

Right-angle side frame die-casting machine: is a structural type of die casting machine, which is different from the C frame die casting machine.

The right angle side frame die casting machine can be divided into two types: integrated type and assembled type.

Conclusion

There are many different classifications types of die casting machines, the common classification is divided into hot chamber die casting machine and cold chamber die casting machine。

Our Haichen machinery was founded in 2005, Located in Ningbo, Zhejiang, China. HAICHEN specializes in the production and sale of hot chamber die-casting machines, cold chamber die casting machines, servo die casting machines, magnesium alloy die casting machines and rela.tive auxlliary equipment.

HAlCHEN always places more emphasis on the technology and management, Because of its ad.vanced technology, high quality and effective management, “HAlCHEN’s hot chamber as well ascold chamber dle-casting machines has won the trust from our cllents at home and abroad.