Ceramic melting crucibles are containers specifically designed for melting metals at high temperatures, widely used in fields such as jewelry casting, dental casting, and industrial metal treatment.

They are typically made of high-purity ceramic materials such as silica, which offer excellent heat resistance, corrosion resistance, and thermal shock resistance.

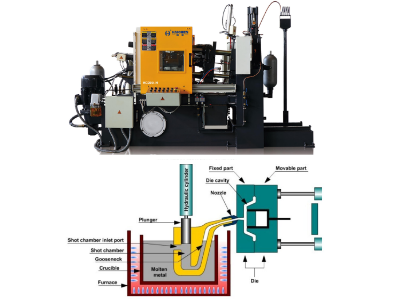

Die casting is a metal casting process in which molten metal is injected into a mold cavity at high pressure.

The crucible is used in it to melt and hold the molten metal, which is then transferred to the die casting machine.

Ceramic crucibles are widely used due to their resistance to high temperatures, corrosion resistance, and chemical stability.

What Is A Ceramic Crucible?

A crucible is a container designed for extreme temperature applications, particularly in melting metals. Ceramics, with non-reactive surfaces, are crucial for making crucibles.

Ceramic crucibles, including quartz, corundum, boron nitride, zirconia, etc., have been used in metalworking since 5000 BC. Their design has evolved with metallurgical advancements.

Various raw minerals can be used to create ceramic crucibles, and the choice depends on the intended application’s temperature and pressure requirements.

Typical Ceramic Crucibles

- Alumina Crucible

- Zirconia Toughened Alumina Crucible

- Graphite Crucible

Alumina Crucible

Alumina crucibles are a scientific name for corundum crucibles with about 99.7% of the material being alumina Al2O3, having traces of MgO and SiO2.

Due to their low cost and ability to resist a range of temperature conditions, alumina crucibles are particularly popular.

They are strong and resistant to melting, high temperatures, acid and alkali, rapid cooling, intense heat, and chemical corrosion.

Zirconia Toughened Alumina Crucible

Zirconia Toughened Alumina crucibles are advanced ceramic vessels that combine the high-temperature resistance of alumina with the toughness and durability of zirconia.

Comprising about 90% alumina and 10% zirconia, these crucibles offer a unique balance of mechanical strength and thermal stability.

ZTA crucibles find applications in various high-temperature processes where the simultaneous requirements of strength and resistance to thermal shock are essential.

Their versatility makes them suitable for tasks ranging from the melting of metals to the synthesis of advanced materials.

Graphite Crucible

A graphite crucible, commonly employed for melting non-ferrous metals like gold, silver, aluminum, or brass, offers high-temperature endurance and low reactivity with molten metals.

Comprising carbon material, graphite is often combined with clay, molded, and subjected to high temperatures to create a robust container.

While graphite crucibles share some fragility with ceramic vessels, careful handling is essential.

The inherent softness of graphite extends its utility to applications such as lubricant formulations, structural materials, and metallic alloys.

After two hours at 500 degrees Fahrenheit (260 degrees Celsius) in the oven, the crucible should be slowly cooled in a dry area to prevent splitting due to moisture.

Wet crucibles require drying off and reconditioning, and they should never be stored near moisture.

The role of ceramic melting crucibles in die casting

- Molten metal

- Temperature Retention and Control

- Preventing Metal Oxidation and Contamination

- Safety and Operational Efficiency

- Integration into Die-Casting Systems

Molten metal

First, in die-casting, melting metal is the initial step,crucibles withstand high temperatures through specialized design.

They heat solid metals like aluminum, zinc, and magnesium alloys to a molten state.

Additionally, crucibles use materials such as graphite, ceramic, or special alloys that resist high temperatures.

For example, these materials allow crucibles to handle aluminum melting at about 660°C without issues.

Similarly, for zinc melting around 420°C, crucibles remain stable.

Temperature Retention and Control

During die casting, the molten metal must maintain a stable molten state to enable continuous injection into the mold.

Second, the crucible is usually integrated with a heating system and uses sensors like thermocouples to precisely control temperature

This prevents the molten metal from solidifying or overheating and in turn ensures the metallurgical quality and consistency of die castings.

For example, in hot-chamber die casting machines, the crucible uses automatic control devices to maintain the magnesium alloy temperature at around 680°C, avoiding significant fluctuations.

Preventing Metal Oxidation and Contamination

The material of the crucible is corrosion-resistant and chemically stable.

So it avoids adverse reactions with molten metal and prevents the molten metal from getting contaminated.

For example, graphite crucibles effectively inhibit metal oxidation, reduce dross formation, and thus improve the purity and strength of die castings.

Additionally, some crucible designs allow the introduction of protective gases, which further prevents oxidation.

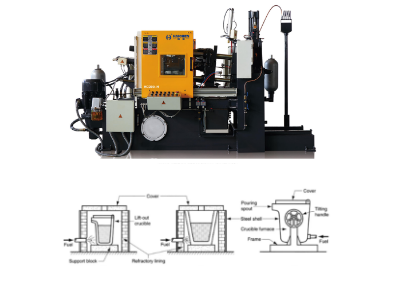

Safety and Operational Efficiency

They prevent molten metal from splashing, reduce heat loss, and enhance thermal efficiency.

Next, they are usually fixed in die-casting machines, with insulating liners around them to retain heat.

Meanwhile, tilting or injection systems facilitate the transfer of molten metal, lowering the risk of manual operation.

Finally, preheating crucibles and installing them correctly can avoid cracking and accidents.

Integration into Die-Casting Systems

In hot-chamber die-casting machines, crucibles connect directly to injection systems, transferring molten metal and controlling flow pressure.

Thus, crucibles serve not only as melting containers but also as core components in the die-casting process, ensuring a stable supply of molten metal.

Haichen ceramic melting crucibles

- Material Selection

- Design Features

- Performance Requirements

Material Selection

Haichen’s ceramic crucibles commonly use materials such as sintered alumina, sintered glassy carbon, magnesia, and porous zircon.

These materials suit different metal alloys; for instance, alumina crucibles work well with gold and base metals.

While silicon carbide crucibles are particularly suitable for aluminum alloy die casting because aluminum and alumina do not corrode silicon carbide.

Design Features

Moreover, Haichen usually designs die-casting crucibles in a basin shape—wide and shallow—to facilitate the pouring and transfer of molten metal.

They offer various size and capacity options, which accommodate both small-batch and large-scale die-casting operations.

Performance Requirements

Additionally, Haichen’s crucibles have high thermal shock resistance to withstand rapid temperature changes, such as heating from room temperature to melting temperature.

They also feature good mechanical strength, so they do not crack during movement or in high-pressure environments, thus extending their service life.