When commissioning an die-casting machine accumulator, there are a number of recommendations and steps that need to be followed to ensure its safe and efficient operation.

During die casting, molten metal must fill intricate moulds within milliseconds, with the accumulator serving as the power source for the hydraulic system.

The accumulator functions by supporting the high-pressure, rapid and precise metal injection process through its energy storage and release mechanism.

We observe the video in the accumulator, there is an excess of nitrogen, the pressure reaches about 140, then it means that the hydraulic oil accumulator can not be flushed into too much. The excess nitrogen must be drained to give room for the hydraulic fluid accumulator to flow out.

- Open the shut-off valve

- Check the nitrogen pressure

- Observe the boost pressure

Open the shut-off valve

Open the shut-off valve and drain the existing hydraulic oil from the nitrogen cylinder so that only nitrogen is retained to make the data more accurate. After draining, close the shut-off valve.

Accumulator shut-off valves for die casting machinesCheck the nitrogen pressure

Check the nitrogen pressure of the accumulator. Adjust to regular pressure requirement: 100-110.

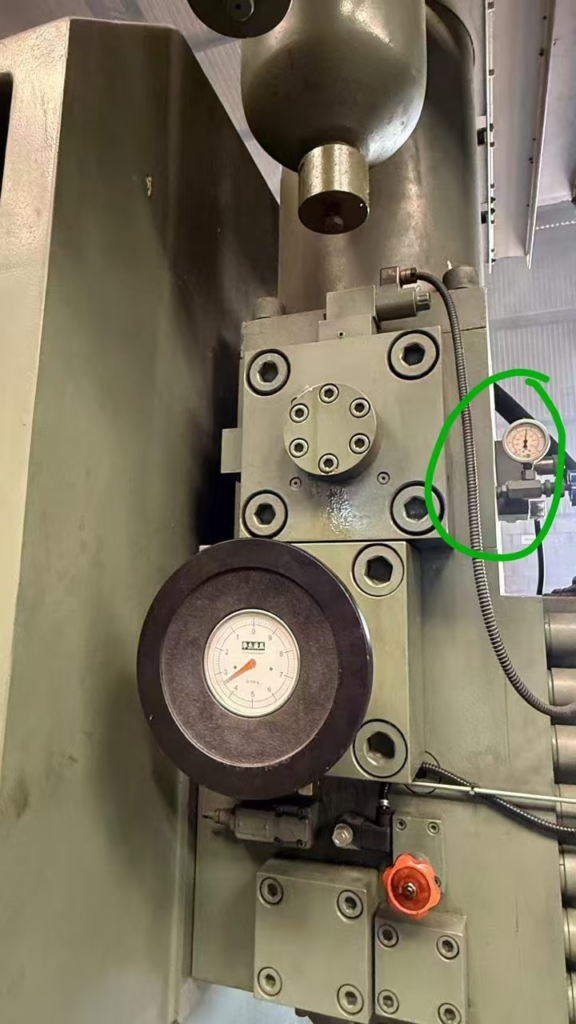

Die Casting Accumulator Pressure GaugeObserve the boost pressure

When running, observe the boost pressure, whether there is any change. Normal 90-100

Then observe the fast pressure gauge, whether it is 100-110.

The pressure injection accumulator is not regulated by an electronic valve, so the PLC setting is normal.

The pressure to be released by the booster injection action needs to be fine-tuned by means of individual black wheel discs with handles, which need to be fine-tuned manually according to each product holder.

Haichen Solutions for Accumulator Failure Issues

We are constantly optimizing the quality of our die-casting machines.

- Optimising Material Selection

- Improving Hydraulic System Design

- Regular Replacement of Seals

- Enhanced Thermal Management

- Routine Inspection and Maintenance

Optimising Material Selection

Selecting materials with excellent high-temperature strength and fatigue resistance, such as specially heat-treated H13 steel, can significantly extend the service life of accumulators.

Improving Hydraulic System Design

Ensure stable hydraulic system pressure and conduct regular inspections and maintenance of accumulators and associated components to minimise damage caused by pressure fluctuations.

Regular Replacement of Seals

Promptly replace aged or damaged seals to prevent hydraulic fluid leakage or pressure loss.

Enhanced Thermal Management

Reduce accumulator operating temperatures by improving cooling systems or employing more efficient heat dissipation materials, thereby mitigating thermal fatigue effects.

Routine Inspection and Maintenance

Conduct periodic accumulator inspections to identify potential issues early, facilitating timely repairs or replacements.

Failures in accumulators for cold-chamber die-casting machines are typically associated with material fatigue, thermal fatigue, suboptimal hydraulic system design, and seal ageing. By optimising material selection, refining hydraulic system design, enhancing thermal management, and implementing regular maintenance, the service life of accumulators can be effectively extended, thereby improving system reliability.