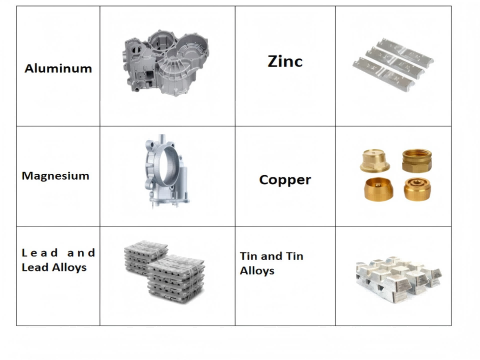

Die casting 6 best materials mainly include aluminum, zinc, magnesium, copper, lead and lead alloys, tin and tin alloys.

Die casting is a manufacturing process in which molten metal is forced into a mold cavity under high pressure. The choice of material significantly impacts the product’s properties, durability, and application.

Die casting 6 best materials

Aluminum of die casting 6 best materials

- Properties: Lightweight, corrosion-resistant, high strength-to-weight ratio, excellent thermal and electrical conductivity.

- Applications: Automotive parts (engine components, transmission cases), aerospace components, and consumer electronics.

- Advantages:

Easy to cast and machine.

High resistance to temperature and wear.

Zinc

- Properties: Low melting point, high ductility, excellent impact strength, and good corrosion resistance.

- Applications: Small, intricate parts such as connectors, locks, gears, and automotive components.

- Advantages:

Can cast thin walls and complex shapes.

Longer die life due to its lower melting temperature.

Magnesium of die casting 6 best materials

Properties: Very lightweight, good strength-to-weight ratio, excellent machinability, and good electromagnetic interference shielding.

Applications: Automotive parts (steering components, housings), aerospace components, and electronics casings.

Advantages:

Ideal for reducing weight without sacrificing strength.

High dimensional stability in die-cast parts.

Copper of die casting 6 best materials

- Properties: Excellent thermal and electrical conductivity, high corrosion resistance, and exceptional strength.

- Applications: Electrical connectors, plumbing components, and industrial machinery parts.

- Advantages:

Excellent for parts requiring high conductivity and resistance to wear.

And good thermal performance for heat-sensitive applications.

Lead and Lead Alloys

- Properties: High density, corrosion resistance, and malleability.

- Applications: Specialty items such as weights, battery terminals, and radiation shielding components.

- Advantages:

Useful for heavy components.

Effective for sealing and resistance to environmental factors.

Tin and Tin Alloys

Properties: Low melting point, excellent corrosion resistance, and good ductility.

Applications: Decorative items, bearings, and precision components.

Advantages:

- Good for thin, detailed, and precision parts.

- Often used in food-safe applications due to its non-toxicity.

Factors to consider when choosing a material

Strength and Weight Requirements

Match the material’s mechanical properties to the part’s needs.

Corrosion Resistance

Especially critical for outdoor or marine applications.

Thermal and Electrical Conductivity

Important for electronic or heat-sensitive parts.

Cost Efficiency

Evaluate material cost and production efficiency.

Durability and Longevity

Especially for high-wear applications.

Haichen die casting best material

Haichen Die Casting is a professional manufacturer of high quality hot chamber die casting machines and cold chamber die casting machines, which are widely used in automotive, electronics and industrial equipment industries.

The “best material” for Haichen Die Casting depends on the specific application and performance requirements.

Selecting the right material ensures optimal performance, durability, and cost-effectiveness for the die-cast product.