The working concept of conveyors in die casting machines involves moving parts efficiently through the production stages, from casting to cooling.

The implementation of conveyor systems significantly improves the productivity and automation of the die casting process.

The modern die casting industry cannot operate without these systems because of their impact on production efficiency, decrease in manual labor, and consistent quality of the manufactured parts.

The purpose of this article is to analyze the operation principle of the conveyors in die casting machines and their impact on the productivity of the entire process.

Introduction to Die Casting Conveyors

The die casting conveyors are systems that operate within a die-casting system and are built to withstand the heat and weight of die casting operations.

There is a need to transport the molded components from the die casting machines to the cooling, trimming, inspection, and final packaging stations.

Working concept of conveyors for die casting machine

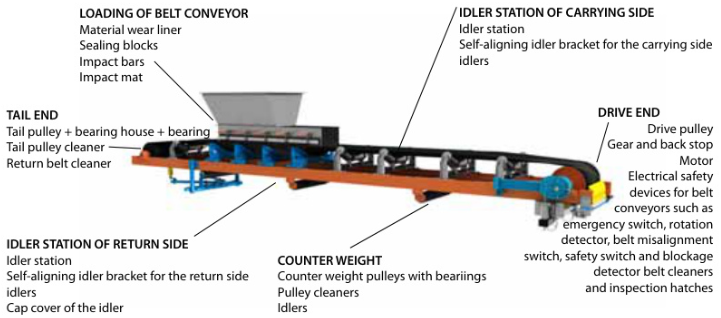

Conveyor systems in die casting plants are meant to aid the flow of materials to reduce processing time in the production line. Below are the components of conveyors systems.

- Material Feeding

- Transfer of Molten Metal

- Cooling and Solidification

- Ejection and Packaging

Material Feeding

The starting stage of die casting requires the conveying of some raw materials, metals in the form of inogots or pellets.

The casting machine requires a continuous supply of materials, and thus a conveyor system is necessary to transport the materials from the storage section to the machine.

Transfer of Molten Metal

Some modern conveyor systems are design and equip to handle molten metal, transferring it from the melting furnaces to the casting machines’ injection units.

This requires conveyors to withstand extreme temperatures and ensure safe delivery of materials, something critical for maintaining production efficiency.

Cooling and Solidification

The parts must also cool down after the metal is discharge into the die and the die is close for solidification.

The now solid parts must cool down and for this, conveyors to transport the molds to the various cooling stations.

Controlled cooling is essential to provide the necessary uniform temperature to the molds, minimizing the risk of thermal stresses.

Ejection and Packaging

Parts are cooled in mold and are eject out. For further quality control, these parts are sent through additional processing such as finishing or quality inspection.

Conveyors that are use to transport parts reduce manual labor, increase efficiency, and minimize damage to the parts.

Conveyor and Mold Cooling System Interaction

Interaction The flow of mold and conveyor cooling directly affects the efficiency of die-casting:

Internal Mold Cooling System

- Water-cooling pipes are place within the mold to circulate water through the mold, regulating the temperature of the mold. Water is kept in the range of 150–250°C.

- Purpose: Minimizes mold opening cycles by reducing shrinkage and sticking.

External Conveyor Cooling System

- Over the conveyor, air cooling or water mist spray nozzles are place to enhance the rate of cooling on the cast.

- Cooperative Logic: Mold cooling regulates solidification while conveyor cooling is in charge of removing the heat. The two work together to control temperature through a PLC.

Advantages of Haichen-die casting machine conveyors

Haichen’s die casting machines conveyors are design with a robust structure which meets the requirements of heavy loads and high temperatures, seamlessly integrating with die casting operations.

Haichen Machinery integrates advanced control systems which optimally synchronize with casting rhythm for the best productivity. Modular conveyors are easily tailore to different production line layouts.

Die Casting Machine Conveyor Belt Maintenance

Daily servicing

The sets of idlers and rollers should be cleane each shift to avoid snagging of residual materials. Check the sensitivity of the tensioner to constant tension to ensure it is optimal.

Long term servicing

Check the chain/belt joints every six months. The preferred joints are those that are hot vulcanize with a strength over 90%. With regards to belt storage, avoid direct sunlight and damp settings to reduce the chances of mold and distortion.

Safety regulations

No heavily laden machine starts are permit. The machine must be stop immediately if belt deviation surpasses five degrees.

The incorporation of conveyor belts in the die casting process enables manufacturers to enhance productivity, efficiency, safety, and quality control.

The continuous advancement of technology is also increasing the efficiency of conveyor belts thereby increasing the efficiency of die casting operations.