The working principle of chiller is to circulate the coolant through the mold to absorb heat, then cool it in the evaporator of the chiller and then circulate it.

Like other manufacturing processes, die casting requires strict temperature regulation during the entire process of production to maintain quality. This is because the thermal dynamics of the mold directly dictate the metallurgical integrity and dimensional accuracy of the final casting.

Die Casting machines relies on chillers to ensure proper cooling of molten metals, allowing them to solidify. Comprehending the workings of a chiller assists in perfecting die casting techniques. Essentially, the chiller acts as the central thermostat for the entire operation, enabling repeatable cycles and consistent output.

This article discusses the importance of chillers in die casting machines and the significance in the total process.We will break down its working principle, key components, and how integrated solutions, like those from HAICHEN, elevate production efficiency and part quality.

The Role of Temperature Control

A die casting machine requires accurate control of temperature as it impacts the final product’s quality. The temperature of the mold needs to remain constant for proper metal injection and freezing. An overly hot mold could lead to metal sticking, while a cold one could lead to incomplete filling. A chiller allows for the ideal temperature to be maintained by extracting heat out of the mold ensuring that the excess is removed.

How a Chiller Works

A chiller works on the refrigeration principle. It has a refrigerant that absorbs heat from the mold and conveys it to a heat exchanger. The heat exchanger removes the heat to the environment through a cooling tower or fans. This continuous cycle of heat absorption and dissipation keeps the mold at a stable temperature, ensuring consistent casting quality.

Components of a Chiller System

A standard chiller system is made up of:

- Compressor – This part of the system compresses the refrigerant which in turn increases both its temperature and pressure.

- Condenser – The hot and high-pressure refrigerant gas is cooled and condenses into a liquid here.

- Expansion valve – The refrigerant is now in liquid form and passes through this valve. After which, the valves pressure and temperature will decrease turning it into a cold, low-pressure liquid.

- Evaporator – The cold refrigerant now has to absorb heat and cool from the mold, but to do this the refrigerant must turn back into a gas.

- Circulating pump – This pump is responsible to move the coolant which is usually water or some other liquid through the mold. As it moves through the mold it has to absorb heat and then be cooled down by the evaporator.

Working principle of chiller

The main job of a water chiller is to quickly and efficiently cool the die casting mold. This is how a water chiller functions.

The coolant that is heated, returns back to the chiller, circulating through the system.

- Chillers frequently circulate coolant through the die casting mold. This coolant is usually water or some other special liquid.

- The coolant takes away heat as it moves between the channels in the mold, helping to cool the molten metal in it faster.

- Refrigeration Cycle: The thermal exchange takes place in the chiller where the coolant relinquishes heat to the refrigerant, which evaporates, absorbing the coolant’s heat and subsequently cooling it.

- Compressor and Condenser: The absorbed heat in the refrigerant gas is then compressed by the compressor, increasing its temperature and pressure. The high-temperature, high-pressure refrigerant gas moves to the condenser where it cools and condenses to a liquid state.

- Expansion and Recirculation: They pass the liquid refrigerant through an expansion valve which lowers both pressure and temperature, transforming it into a low-pressure cold liquid. The evaporator is where this cold refrigerant goes to repeat the cycle.

- Efficient Cooling: The temperature-critical fluid circulation in the mold is crucial for maintaining quality and consistency during casting, which reintroduces the need for the coolant to be re-pumped into the mold.

Hot Chamber Die Casting

In hot chamber die casting, the chiller is particularly important due to the continuous flow of molten metal. The chiller helps maintain the temperature of the molten metal and the mold, ensuring smooth and consistent casting operations.

The integrated cooling system in hot chamber machines, such as those provided by HAICHEN, ensures that the molten metal solidifies quickly and uniformly, improving part quality and production efficiency.

Die Casting Machine Manufacturer with Integrated Chiller Solutions

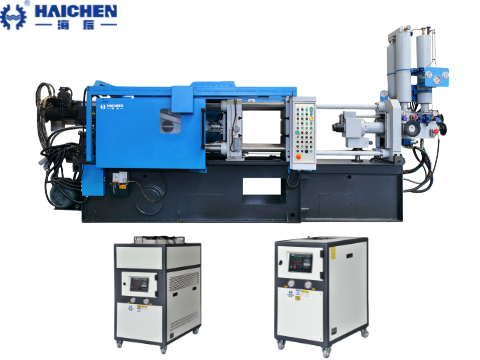

HAICHEN is one of the leading manufacturers of die casting machines and chillers with advanced systems.

Haichen chillers excel in maintaining precise temperature control with state-of-the-art technology. Improved part quality and shortened cycle time are achieve through consistent cooling.

We strive to improve the die casting cycle with our chiller systems for maximum efficiency and effectiveness.

HAICHEN’s Integrated Chiller Solutions: Beyond Basic Cooling

HAICHEN designs its chiller systems not as standalone units, but as fully integrated components of the die casting cell. This integration delivers targeted advantages:

- Process-Specific Cooling Zones

- Energy-Efficient Intelligence

- Direct Machine Interface

Process-Specific Cooling Zones:

For complex molds, HAICHEN systems can support multiple independent cooling circuits. This allows different sections of the mold (e.g., a thin wall vs. a thick boss) to be held at different optimal temperatures, guaranteeing uniform part solidification and higher quality.

Energy-Efficient Intelligence:

HAICHEN chillers often feature variable frequency drive (VFD) compressors and pumps. Instead of simply turning on and off, these components adjust their power output to match the exact cooling demand in real-time, reducing energy consumption by up to 30-40% compared to fixed-speed models.

Direct Machine Interface:

The chiller’s control system communicates directly with the HAICHEN die casting machine’s main HMI. Operators can monitor and adjust chiller setpoints from the same screen that controls injection parameters, enabling centralized process management. Alarms from the chiller are displayed prominently, allowing for quick troubleshooting and preventing defective production runs.

Chillers enhance the die casting process by minimizing cycle times while improving surface finish and metallurgical quality.

Uniform solidification of the metal is achieve through rapid cooling of the mold which increases productivity.

Manufacturers are able to maintain a competitive market edge by understanding the Working principle of chiller, properly maintaining it, and ensuring high-quality production.