The uses of release agent mixer is to automatically apply release agent to the mold, ensuring easy part ejection and protecting the mold.

Release agents play an integral role during die casting by ensuring that the casted components are removed from the mold easily and do not get stuck or get damaged.

A release agent mixer is a piece of equipment that prepares and mixes the release agent solution, ensuring uniform distribution for easy application.

Achieving high-quality or optimal results during die casting processing hinges on the quality of release agents and mixers.

This article aims to discuss the importance of release agent mixers in die casting processes and how they enhance the efficiency and quality of the die casting processes.

The uses of Release Agent Mixer

The purpose of a die-casting machine release agent mixer is to uniformly and precisely dispense release agent onto the mold surface.

- Prevent adhesion

- Improve the quality of the casting

- Extend the life of the mold

- Improve production efficiency

- Reduce material waste

- Improve operational consistency

- Reduce post-processing work

Prevent adhesion

The release agent creates a protective barrier between the mold and the molten metal. This ensures that the molten metal does not stick to the mold and helps the casting to be easily separate from the mold.

Improve the quality of the casting

The release agent helps improve the surface quality of the casting as well as the overall quality by lessening the friction and wear between the mold and metal.

Extend the life of the mold

Protects the mold from damage due to friction and heat, resulting in a longer service life of the mold.

Improve production efficiency

The automating application of release agents eliminates manual processes, quickens the pace of work, and enhances overall productivity, thus improving production efficiency.

Reduce material waste

The amount of release agent used can be strictly monitored and controlled thus wastage is minimized and production cost is lowered.

Improve operational consistency

Achieve uniform and consistent application of release agent during every die-casting cycle, thus improving casting quality uniformity.

Reduce post-processing work

Since the release agent can reduce defects on the surface of the casting, subsequent grinding and finishing work can be reduce.

Working Principles

The mixer operates in three stages:

- Proportioning: Concentrated agent and water are added to the mixing tank either through volumetric pumps or through gravity flow systems.

- Homogenization: Stirring Mechanically or through Compressed air applied at 1500-1800 rpm will create a stable emulsion in the mixing tank after 15 to 30 minutes.

- Pressurized Transfer: The emulsion is pump through the spray nozzles at a pressure of 0.3-0.6 MPa, synchronized with die opening/closing cycles.

Efficiency Innovations

- In-line Mixing: For In-line mixing, agent injection cycles are replace by external pre-mixing, reducing the cycle by 30-40%.

- Compatibility with Vacuum Casting: The system can operate under vacuum conditions to reduce gas porosity.

Benefits of Using a Release Agent Mixer

- Consistent Part Quality

- Improved Mold Life

- Enhanced Efficiency

- Safety and Environmental Benefits

Consistent Part Quality

A release agent mixer provides consistent coverage of release agent on the mold surface by evenly distributing the release agent. This ensures that every part produced is a defect-free high-quality repeatable part.

Improved Mold Life

Correct application of the release agent each time reduces the wear and tear on the mold. This increases the usable life of the mold and reduces the maintenance costs that would have been incurred.

Enhanced Efficiency

The release agent mixer improves the efficiency of the die casting process by ensuring that the release agent is prepared for application at all times. This decreases the amount of time spent on non-productive activities and improves efficiency for production as a whole.

Safety and Environmental Benefits

Release agent mixers increase workplace safety by ensuring the proper dilution and mixing of the release agent. This mixer reduces exposure to concentrated chemicals and reduces the likelihood of any work-related accidents.

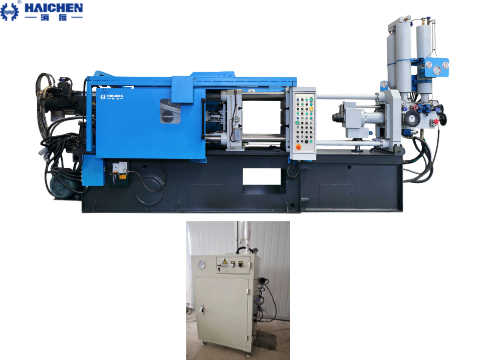

Advantages of Haichen die casting machine release agent mixer

Improved Efficiency

Haichen’s release agent mixers automate the application process which reduces time and manual work. Such automation increases productivity because every mold is coated with the exact amount of release agent needed thus consistent and high-quality castings.

Improved Mold Protection

The mixers protect the molds by minimizing the overall heat and wear, which extends the service life of the molds. The equal distribution of release agent prevents the creation of hot spots which damages the mold.

A release agent mixer is a key component of a die casting machine which assists the operator to improve the overall efficiency and effectiveness of the machine as well as the processes.

Proper lubrication of the die assists in better casting quality and prolonging the die life.