Hydraulic system maintenance procedure mainly includes inspection procedure, choose the right hydraulic oil, prevent moisture and air, and fault diagnosis and maintenance technology etc.,

Hydraulic system maintenance procedures are key to ensuring long-term, stable operation and extended service life of your hydraulic system.

It is a multifaceted process that encompasses cleaning, preventative maintenance, safe operation, and hydraulic fluid management. By following these maintenance procedures, you can ensure long-term, stable operation and extended service life of your hydraulic system.

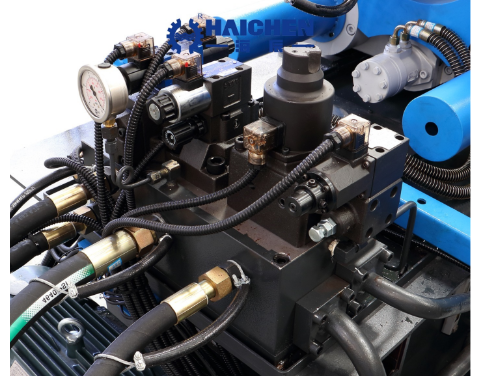

We will analyze what is the maintenance procedure for a hydraulic system?The specific maintenance procedure for a hydraulic system in the die casting machine are as following:

Inspection procedure

A general visual inspection daily to ensure there is no visible damage or missing parts and that all labels are visible and readable. And regular inspection to check the oil level in the hydraulic oil tank weekly to ensure it is adequate.

Power Off and Lockout

Shut off the power to the equipment and use the lockout device (LOTO) to ensure the system is completely de-energized.

System Depressurization and Reset

- Place hydraulic components in the safe/neutral position to relieve residual system pressure.

- Slowly release high-pressure line pressure to avoid splashing.

Work Environment Preparation

- Isolate the work area and ensure the machine is parked on a flat, solid surface

- Wear protective equipment (gloves, goggles, etc.)

Choose the right hydraulic oil

Qualified hydraulic oil is the guarantee for the reliable operation of the hydraulic system. On the market, there are different types of hydraulic oil for die casting machines.Therefore, choosing the right hydraulic oil is crucial to maintaining the hydraulic system.

Haichen die casting machines use Hydraulic oil brands usually like Shell Tellus, Mobil DTE,Hyspin, Castrol AW(AW Hydraulic)and so on. They are all ensuring broad compatibility. And the Standard Anti-Wear Oils: HM-grade oils (VG 32, 46, 68).

Determine key performance parameters

- Viscosity: Select the appropriate viscosity grade based on the operating temperature. Low-viscosity oil is required for low-temperature environments, while high-viscosity oil is required for high-temperature environments.

- Additives: Select oils containing antioxidant and anti-corrosion additives to extend system life.

- Environmental performance: Long-life oils that meet environmental standards are preferred.

Verify oil quality

- Appearance and odor: Deteriorated hydraulic oil appears dark brown or milky white and has an unpleasant odor. Such oils must not be used.

- Cleanliness: New oil should be added through a funnel with a filter and stored in a dust-free environment.

- Moisture detection: Turbid oil indicates water or air intrusion and requires immediate replacement and seal inspection.

Handling special operating conditions

- Highly water-based hydraulic systems (such as mining equipment) require the use of fully synthetic fluids to prevent mineral oil and impurities from condensing and clogging the filter elements.

- Servo valve systems require precision filters and should be flushed and checked every 1-2 hours for filter blockage.

Prevent moisture and air

The intrusion of moisture and air will affect the performance of the hydraulic oil and increase the risk of system failure. Thus, measures should be taken to prevent moisture and air from entering the hydraulic oil.

Sealing System and Venting

- After maintenance or changing the oil, completely bleed air from the system according to the manual.

- Ensure the oil pump suction line is always submerged below the oil level and that the suction line is properly sealed to prevent air inhalation.

- Use a double-lip oil seal (not a single-lip seal) on the oil pump drive shaft to enhance sealing.

- The oil return line must be inserted below the oil level in the tank to prevent the introduction of air by oil return shock.

Fuel Tank and Oil Level Management

- Check the oil level in the tank regularly to maintain adequate oil levels (it is recommended to fill the tank to 5 cm below the neck to avoid overfilling or underfilling).

- The fuel tank cap must be securely fastened and can be stored upside down when not in use to minimize air contact.

- Use a desiccant respirator (not a standard respirator cap) to prevent moisture and dust from entering through the respirator opening.

Oil Storage and Refilling

- Hydraulic oil must be stored in a dedicated, sealed container at a constant temperature to prevent condensation and rust contamination from the drum.

- Use clean tools when refilling and filter the oil through a filter to prevent particles and moisture.

Moisture Detection and Treatment

- Detection method: Heat a small amount of oil. If a popping sound is heard, it indicates water and requires immediate oil replacement.

- Regular Draining: Filter oil with high water content multiple times, replacing dry filter paper each time. Drain and flush the system as necessary throughout the year.

- Oil Replacement: Immediately drain and flush the system if milky oil, an odor, or a critical component failure is detected.

System Sealing and Design

- After disconnecting hydraulic lines for maintenance, immediately seal the pipe ends to prevent the intrusion of contaminants and moisture.

- System design should minimize exposure to moisture, such as by using moisture-proof seals and optimizing piping layouts.

Prevent dust and impurities

The intrusion of dust and impurities will accelerate the wear of hydraulic components and affect the normal operation of the system. So measures should be taken to prevent dust and impurities from invading the hydraulic oil.

Cleaning Fueling Tools and Containers

- Before refueling, thoroughly clean fueling tools (such as funnels and oil drums) and filter the hydraulic fluid using a funnel with a fine-mesh filter.

- Store hydraulic fluid in sealed containers and use clean, covered containers for transfer.

- Clean the area around the fuel filler port before opening to prevent dust from entering.

- Clean up hydraulic oil in the die casting machine

Filtration of New Oil

New hydraulic oil must be pre-filtered before adding it to the system to remove potential contaminants.

Regularly replace the hydraulic oil and filter

- Replace the hydraulic oil and filter after the first 50 hours of operation to remove any remaining manufacturing impurities. Subsequent replacements should be made according to the manufacturer’s schedule.

- When replacing the filter, clean the oil port first. Fill the new filter with oil before installing. After replacement, run the vehicle at idle for 5 minutes to allow the air to escape.

Fault diagnosis and maintenance technology

When a hydraulic system fails, it is necessary to perform fault diagnosis and adopt appropriate maintenance technology to solve the problem.

This includes using modern technology to determine the source of the fault and summarizing the main points of maintenance based on a large amount of data analysis.

Establish a preventive maintenance program

Develop a plan based on system operating conditions, including continuous operating hours (e.g., 24/7), maximum load ratio (>70%), and environmental conditions (dust/high temperature).

Fluid Management

Regularly replace hydraulic oil and filters, using oil that meets specifications. Monitor fluid contamination (e.g., particle count) to prevent contaminants from causing component failure.

Heat Control

Maintain system cooling, clean radiator fins, and prevent corrosion caused by oil-water mixing.

Pipe and Seal Inspection

Regularly replace aging hoses and ensure joints are tight to prevent leaks.

Filter Maintenance

Replace filter elements based on operating hours or operating conditions. Breather filters also require maintenance.

Through above steps of the maintenance procedure for a hydraulic system, the hydraulic system can be effectively maintained and serviced. It can extend the service life. And ensure the normal and stable operation of mechanical equipments.

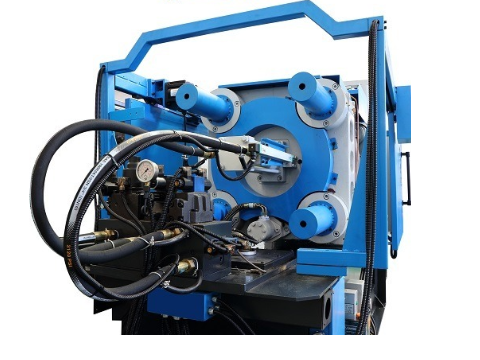

Haichen die casting machine

Haichen is one Chinese die casting machine for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine .They have durable and highly precise features. Haichen also produces die casting machine auxiliary equipment. Such as conveyor, vacuum machine, industrial robot, sprayer and so on.