Choose mould temperature controller need consider factors like metal material type, mold structure, select cooling medium, and so on.

Mold temperature is one of the most important parameters in the die casting process. It directly affects the quality of castings, production efficiency and the service life of the mold.

The selection of mold temperature controller should focus on alloy process temperature, combine control accuracy with system performance, and strengthen preheating and thermal balance management.

When selecting a die-casting mold temperature controller, give priority to closed-loop water cooling system, and add zoned oil heat regulation for complex scenarios. The key goal is to maintain the mold temperature at around 200°C, reduce defects and extend mold life. For actual application, refer to successful cases: fixed mold 200°C, mobile mold 220°C, pouring temperature 670°C, and dynamic cooling control can achieve zero-defect production.

- Mold type and alloy type of mould temperature controller

- Mold structure and cooling conditions of mould temperature controller

- Selection of cooling medium

- Temperature Sensors and Monitoring Systems

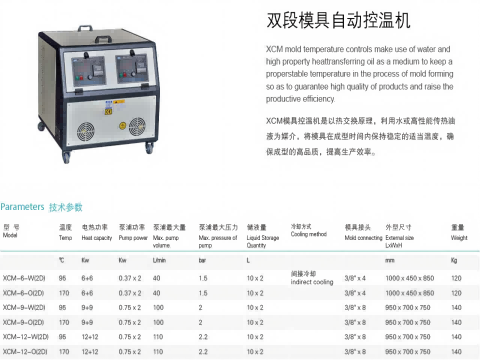

- Power and pump selection of mould temperature controller

To choose mould temperature controller for the die casting machine, above are the detailed factors:

Mold type and alloy type of mould temperature controller

- Temperature accuracy

- Thermal balance design

- Safety protection

Different types of die casting alloys have different requirements for mold temperature.The recommended operating temperature for alloy moulds:

- zinc alloys is 160-200°C

- magnesium alloys are 180-240°C

- aluminum alloys are 200-250°C

- copper alloys are 280-350°C

Temperature accuracy

Within ±10℃ (such as TT-OIL300) to avoid shrinkage and thermal cracking of castings caused by temperature fluctuations.

Thermal balance design

Cooling unit: needs to cooperate with the mold’s own circulating water system to maintain the thermal balance of the cavity.

Spot cooling system: Force cooling of hot spots (such as gates and thick walls) to avoid local overheating.

Safety protection

Magnesium alloy die casting requires explosion-proof design, and water spray cooling is prohibited.

Equipped with automatic leakage detection, electronic temperature limiter and fault alarm.

So it is crucial to choose appropriate mold temperature controller according to the type of alloy used.

Haichen is one Chinese die casting machine manufcturer. Haichen Company offers die-casting machinemould temperature controllers with distinct advantages: employing intelligent control systems, these devices maintain precise and stable mould temperatures with minimal temperature variation.

This directly enhances the consistency of casting surface quality and internal structure. Their efficient heating and cooling systems reduce production cycles while lowering energy consumption. The robust construction ensures long-term, stable operation within the high-temperature, dusty environments typical of die-casting workshops. Requiring minimal maintenance, it provides reliable support for achieving high productivity and low operating costs.

Mold structure and cooling conditions of mould temperature controller

- Cooling system type

- Impact of temperature control imbalance

- Key measures to optimize cooling

The thermal balance of the mold has an important influence on the mold temperature control. Factors such as the mold preheating temperature, pouring temperature, alloy liquid capacity. And mold volume, layout of the casting and overflow system, and mold cooling conditions will affect the thermal balance. Therefore, when choosing mold temperature controller, these factors must be considered to achieve a good thermal balance.

Cooling system type

- High-pressure cooling: For large molds or hot spots, high-pressure pumps (>10 bar) are used to quickly cool down the mold

- Fine spot cooling: used for local high-temperature areas such as cores and small inserts to eliminate shrinkage holes

- High- and low-pressure dual circuits: The integrated mold uses a combination of high-pressure cooling (core/slide) and low-pressure cooling (overall mold)

Impact of temperature control imbalance

- Temperature is too high:

Casting surface depression, shrinkage cavity, hot bubbles;

Mold sticks to aluminum, ejection deformation;

Local overheating causes mold steel tempering softening and strength reduction. - Temperature is too low:

Poor metal liquid fluidity, cold shut, insufficient filling;

Increased mold thermal stress, surface thermal cracking. - Temperature fluctuation:

Casting size is unstable (case);

Mold periodic expansion/contraction, shortened life

Key measures to optimize cooling

- Thermal balance design:

- preset temperature control points according to the casting structure, and achieve dynamic thermal balance through fixed-point cooling of the heat node.

- Mold release agent combination:

- use minimum spraying technology (powder/oil-based mold release agent) to reduce direct contact of cooling water with the mold surface and avoid temperature difference stress cracks.

- Advantages of temperature control island technology:

- Independent temperature control in different areas to solve hot spots of complex molds.

Selection of cooling medium

- Water cooling (pure water or with antifreeze)

- Thermal oil

- Compressed air

Water cooling (pure water or with antifreeze)

- Temperature range: 20°C–95°C (normal pressure) or up to 400°C (pressurized system).

Standard water temperature controller: 120–160°C (pressurized) - Advantages: high heat transfer efficiency, low cost, environmentally friendly and easy to obtain,

- suitable for precision injection molding (inlet and outlet water temperature difference must be ≤2°C)

- Application scenario:

Conventional cooling of mold surface temperature 20–60°C. - High temperature water heating/cooling system (such as rapid hot and cold injection molding, up to 160°C).

Thermal oil

- Temperature range: up to 200°C (conventional models) or 350°C (special equipment)

- Advantages: good high temperature stability, no need for pressurization system

- Application scenarios:

- High temperature molding (such as mold temperature control of 90–200°C)

- Temperature maintenance of extrusion rollers or large molds

Compressed air

Special applications

- Core area cooling (e.g. CPC system uses -15°C compressed cold air)

- Mold dew removal (control air dew point 2–8°C to prevent condensation)

Water is a good heat transfer medium and is easy to control; oil has a higher specific heat capacity and can provide more uniform cooling; air as a cooling medium is less efficient but has a lower cost. It is key to select the right cooling medium according to specific application needs and environmental requirements.

Temperature Sensors and Monitoring Systems

- Limitations of traditional sensors

- Innovation of high-precision temperature sensing mechanism

- Application of non-contact sensors

Limitations of traditional sensors

Thermocouples have the defects of single-point measurement and slow temperature change response. They are prone to errors (±20°C) when the temperature fluctuates rapidly, and cannot fully monitor the internal temperature of the mold.

Thermal imagers can only measure surface temperature and have no monitoring capability for internal temperature distribution.

Innovation of high-precision temperature sensing mechanism

- The new temperature sensing mechanism (such as) reduces the error to ±5°C through the gap between the temperature sensing insert and the temperature sensing rod (gap 0.005–0.01mm).

- The structure includes a horizontal temperature sensing blind hole on the mold core (movable/fixed mold), embedded with a temperature sensing insert, and the center through hole accommodates the temperature sensing rod, which significantly improves the monitoring accuracy.

Application of non-contact sensors

- Infrared temperature sensors (IR Sensors) can monitor the mold temperature range of 180–380°C, realize signal conversion and control through PIC microcontrollers, and are suitable for automation systems

- Temperature sensors are used to measure the temperature of various parts of the mold to ensure uniform temperature distribution and avoid hot and cold spots.

- Advanced temperature monitoring systems, such as thermocouples or thermal imagers, can monitor the mold temperature in real time to ensure stability during production.

Power and pump selection of mould temperature controller

Calculate the required heating power based on the size of the mold, operating temperature and heating time, and select the appropriate pump to meet the flow and pressure requirements. This helps ensure that the mold can quickly and evenly reach the set temperature.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features. Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

By comprehensively considering the above factors, you can effectively choose mould temperature controller to improve the quality and production efficiency of die-casting products. In addition, with the development of die-casting technology, new temperature control methods continue to emerge. The application of these new technologies can further improve the mold temperature control level and meet the needs of complex mold design.