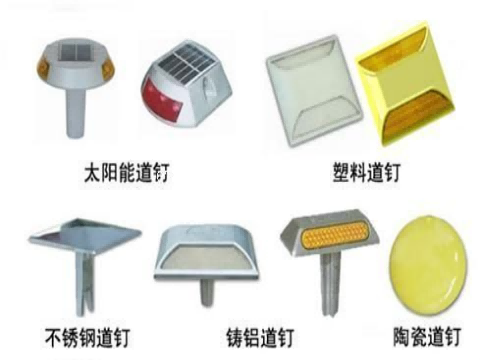

Road studs different types mainly included aluminium road studs, plastic road studs, ceramic road studs, glass ball road studs, four different classification standards.

The material selection for road markers requires a comprehensive consideration of road type (highway/temporary), environmental conditions (climate, traffic volume), and cost. Aluminum and ceramic markers are suitable for high-load permanent projects, plastic and rubber markers are suitable for temporary use, and solar markers address nighttime guidance in areas without power. Among reflective materials, glass beads offer the best long-term performance, while plastic reflectors are more cost-effective but require frequent replacement.

Road studs are components used to fix and support road structures. They are usually installed in the middle of road markings or double yellow lines to remind drivers to drive in lanes. According to different applications and materials, we can divide road studs into below four main types:

- Materials of road studs different types

- Function of road studs different types

- Different types of road studs number of reflective surfaces

- Classification by installation method

- Haichen road stud die casting production solution

Materials of road studs different types

- Aluminum road studs

- Plastic road studs

- Ceramic road studs

- Glass ball road studs

Aluminum road studs

The aluminium road studs have high durability and compressive strength, suitable for sections of road where heavy vehicles pass, such as highways and bridges.

- Features: Lightweight, corrosion-resistant, and highly impact-resistant, suitable for long-term use. The housing is made of aluminum alloy and filled with reflective elements (such as glass beads or plastic reflectors).

- Advantages: High load-bearing capacity (up to 60 tons), suitable for highways and roads with frequent heavy vehicle traffic.

- Disadvantages: Installation requires pre-buried installation, making construction complex and costly.

- Applications: Road centerlines, lane dividers, and highway sections.

Plastic road studs

The plastic road studs with low cost, suitable for areas with low traffic volume, such as hospitals and schools.

- Materials: ABS or PC plastic shell, filled with an epoxy resin and sand mixture for strength, some recycled plastics.

- Features: Low cost and easy installation, but with poor durability and prone to wear.

- Reflective Elements: Typically plastic reflectors or glass beads, requiring a wear-resistant protective coating.

- Applications: Low- and medium-speed roads, factory/hospital/school entrances, temporary projects

Ceramic road studs

The ceramic road studs are more used in the early days, but fragile, not recommended.

- Features: Highly wear-resistant, resistant to extreme temperatures (-40°C to 80°C), and with a lifespan exceeding 10 years.

- Advantages: Highly resistant to pressure, suitable for critical areas such as airport runways and transportation hubs.

- Disadvantages: High initial cost, and specialized equipment required for installation.

- Applications: Highly loaded road sections and long-term projects

Glass ball road studs

Glass ball road studs are more used in the early days, difficult to install, less basic applications.

- Features: Made of tempered safety glass with a reflective coating on the bottom.

- Advantages: Excellent reflectivity and high light transmittance.

- Disadvantages: Brittle, prone to breaking under heavy pressure, requiring additional buffer layer for protection.

- Applications: Road sections requiring high-brightness markings, such as curves and tunnel entrances.

Function of road studs different types

- Passive Reflective Road Studs

- Subtypes

- Active Illuminating Road Studs

- Speed Reduction Function

- Construction and Temporary Use

- Intelligent Interaction Function

Passive Reflective Road Studs

- Function: Enhances road visibility at night and in inclement weather by reflecting vehicle headlights, without the need for an external power source.

- Reflective elements include reflective film (shorter lifespan), plastic reflective sheeting, or glass beads (longer lifespan).

- Provides visual guidance, helping drivers identify lane markings, curves, and shoulder edges.

Subtypes

- Aluminum Road Studs: High strength, suitable for permanent road dividers, and can be densely installed to create raised markings to enforce speed limits.

- Glass Road Studs: 360° reflective and highly resistant to pressure.

- Plastic Road Studs: Low cost but less durable, suitable for temporary projects.

Active Illuminating Road Studs

Function: Actively illuminated by built-in LEDs, making them more visible than reflective road studs. They are particularly suitable for foggy conditions or on sharp curves.

Solar Road Studs: Charged by solar panels during the day, they automatically illuminate at night, eliminating the need for wiring.

- Can display dynamic signals (such as red/green lights indicating go or stop).

- Electrically Powered LED Road Studs: Require an external power source, offer high brightness, but are complex to install.

Speed Reduction Function

- Densely mounted aluminum road studs create a raised marking, forcing vehicles to slow down.

- Some metal road studs can also be used directly as speed bumps.

Construction and Temporary Use

- Temporary road studs are installed with an asphalt or epoxy coating for easy removal after the project is complete.

- Snow Removal Studs: Metal housings protect the reflective elements and resist damage from snow plows.

Intelligent Interaction Function

Solar road studs can be integrated with sensors to dynamically display traffic status (e.g., green light, go, red light, stop).

Different types of road studs number of reflective surfaces

- Single-sided road studs

- Double-sided road studs

Single-sided road studs

It is only one side of the reflector. Unidirectional reflective road studs (single-faced)

Having a reflective surface on only one side, they are used for road guidance in a specific direction.

- Types:

Type B: Unidirectional, single-color (e.g., white, red, etc.). - Single-faced road studs explicitly mention this category and are used for situations requiring directional guidance (e.g., the edge of a one-way street).

- Function: Installed on the edge of a road or on a one-way street, they reflect headlights in a single direction, preventing reverse interference.

Double-sided road studs

These have two sides of the reflector, which can reflect light from multiple angles.

Bidirectional Reflective Road Studs (Dual Reflective Surfaces)

Equipped with reflective surfaces on both sides, these studs can reflect headlights in both directions.

Types

- Type A: Bidirectional reflective, single color (e.g., white).

- Type D: Bidirectional reflective, dual color (e.g., red and white).

- Double-faced road studs: Both and are classified as this type and are suitable for use on bidirectional lane dividers.

- Function: Enhances bidirectional vehicle profile recognition on high-demand sections such as curves, steep slopes, and tunnel entrances.

Classification by installation method

- Embedded solar road studs

- Bonded Road Stud

- Extended Classification

Embedded solar road studs

This type installes in the road surface, suitable for occasions requiring high compression performance.

- Features: The stud is embedded in the road surface after a notch is cut, leaving the surface flush with the road surface, with only the reflective portion exposed (like a traditional “cat’s eye” road stud).

- Applicable Applications: Applications requiring high durability (such as highway medians, tunnels, and bridges).

- Advantages: Strong resistance to rolling resistance and long lifespan; however, installation is complex and requires road surface damage.

Bonded Road Stud

- Features: Directly adhered to the pavement surface using an adhesive (such as epoxy resin or asphalt adhesive), eliminating the need for pre-embedded or anchored road surfaces.

- Applications: Suitable for all types of roads, especially those with medium to low traffic volume (such as urban bypass roads and parking lots).

- Advantages: Easy installation and low cost, but requires high pavement cleanliness and dryness.

Extended Classification

Solar road studs can be further divided into embedded and raised types. The former is used in lane centerlines (which require high pressure resistance), while the latter is used on curbs.

aluminium road studs moulds

Haichen road stud die casting production solution

HAICHEN planned an automatic aluminium road stud production line for them using high-performance cold chamber die casting machines. The solution targeted the features of aluminum road studs:

Optimized Filling for Thin Walls and Deep Pockets

HAICHEN machines have a high-response injection system. Precise multi-stage speed control makes sure the aluminum alloy fills the stud’s thin shell and deep slots smoothly and quickly, avoiding cold shuts or short shots.

Ensured Internal Soundness and Size Stability

The machine’s real-time control system and stable clamping system keep process parameters the same for every shot. This reduces internal pores and gives very consistent die-cast blanks. This is a good base for later automatic assembly.

Efficient Production and Automation Integration

HAICHEN machines connect easily with part-removal robots and sprayers for unattended continuous production. This greatly increases the daily output of aluminum road studs.

Production Results Achieved

After the new line started, the customer’s output per shift for aluminum road studs went up by over 40%. The product yield rate stayed above 98.5%. Because size was more precise and consistent, the efficiency of later reflector assembly also improved a lot. The total manufacturing cost was effectively reduced.

Haichen die casting machine

Haichen is one Chinese die casting machine for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features. Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

Haichen have rich experience of producing aluminium road stud die casting machine.

As per each customer’s specifica demand, we can can supply production including die casting machine, aluminium road stud mould and auxiliary equipment.

These classifications reflect the application requirements and characteristics of road studs in different scenarios. Choosing the right type of road studs can significantly improve road safety and driving comfort.