Die casting vacuum machine advantages include improving casting quality, production efficiency and reducing cost, etc.

Vacuum die-casting machines directly improve efficiency and reduce energy consumption by lowering injection pressure, shortening cycle times, improving yields, and reducing post-processing.

Their core technology lies in reducing gas interference in the vacuum environment, optimizing metal filling behavior, and achieving “high-quality, one-shot molding,” resulting in significant overall benefits.

Die casting vacuum machine advantages have detailed description as below six points:

- Reduce pores of die casting vacuum machine advantages

- Improved Post-Processing Performance

- Improve the mechanical properties of castings

- Improve production efficiency and reduce energy consumption

- Suitable for the production of complex thin-walled parts

- Reduce equipment investment and operating costs

Reduce pores of die casting vacuum machine advantages

Vacuum die casting technology significantly reduces the number and size of pores in castings by removing air from the mold cavity thereby improving the density and mechanical properties of castings.

For example, vacuum die casting can reduce the pores in castings to 1% or even lower, significantly improving the surface quality of castings and the density of internal structures.

- Reduced Porosity Mechanism

- Specific Benefits of die casting vacuum machine

- Reduced Scrap and Cost

Reduced Porosity Mechanism

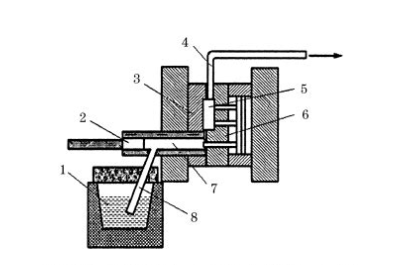

The core of vacuum die casting is to use a vacuum pump to remove 80-90% of gases (such as air and dissolved gases) from the mold cavity before filling.

Thereby minimizing gas entrainment during molten metal filling. This prevents the formation of porosity, which is often caused by gas entrapment or turbulence and can lead to internal voids or weak areas in the casting.

Specific Benefits of die casting vacuum machine

Significantly Reduced Porosity: A vacuum environment eliminates or reduces internal porosity in castings, significantly reducing porosity (increasing density by more than 1%).

Reduced Scrap and Cost

Porosity defects are a major cause of scrap in die castings. By reducing porosity, vacuum technology reduces the defect rate (scrap), thereby reducing material waste and post-processing costs (and reducing scrap by more than 20%).

Improved Post-Processing Performance

Reduced porosity means that castings are less susceptible to defects (such as surface bubbles or cracks) during electroplating, welding, or heat treatment, as the porosity is not exposed after processing.

- Improved Casting Quality

- Improved Mechanical Properties

- Improved Surface Finish

Improved Casting Quality of die casting vacuum machine advantages

Reducing porosity directly improves overall quality, including mechanical properties, surface finish, and dimensional accuracy. Evidence suggests that vacuum die casting is particularly well-suited for demanding industries.

Such as automotive and aerospace, as it enables the production of thinner, more complex, and stronger castings.

Improved Mechanical Properties

- Higher Strength and Toughness: Reduced porosity results in a more uniform and dense internal structure of the casting, thereby improving tensile strength, hardness, and ductility.

- More Consistent Performance: The vacuum environment eliminates gas interference, ensuring uniform metal filling and solidification, reducing weak spots and porosity, and making mechanical properties more predictable.

Improved Surface Finish

- Reduced Surface Defects: The vacuum removes air and oxides, suppressing surface defects such as blisters, pores, and impurities, resulting in a smoother, more aesthetically pleasing casting surface (and, with improved surface finish, reducing the need for post-processing).

- Reduced post-processing costs: Better surface quality means no additional polishing or coating, saving time and money (noting that vacuum die casting can reduce finishing costs).

Improve the mechanical properties of castings

- Reduces Porosity and Improves Density

- Core Mechanism for Improving Mechanical Strength

- Microstructure Optimization

- Reduced Stress Concentration

Die casting vacuum technology can improve the tensile strength and ductility of castings.

Under vacuum conditions, the elongation of magnesium alloys can be increased by nearly 70%. While, under high vacuum conditions, the tensile strength and elongation of castings are further improved.

Reduces Porosity and Improves Density

Vacuum die casting uses vacuum technology (vacuum pump or vacuum valve) to expel air and gas from the mold cavity before metal is injected, significantly reducing porosity defects in the casting.

Reducing porosity directly improves the density of the casting, preventing defects caused by porosity exposure during subsequent processing (such as heat treatment and welding).

Core Mechanism for Improving Mechanical Strength

Improved Tensile Strength and Elongation: Experimental data show that vacuum die-casting of aluminum alloy (AlSi9Cu3) increases its tensile strength by 10% (from 271.6 MPa to 299.8 MPa) and its elongation by 50% (from 1.66% to 2.49%).

Vacuum die-cast pure copper also demonstrates significant increases in strength and ductility.

Microstructure Optimization of die casting vacuum machine advantages

The vacuum environment reduces gas entrapment, allowing the molten metal to evenly fill the mold cavity, resulting in a finer grain structure.

Research indicates that vacuum die-cast parts have a denser crystal structure and are 20%-25% stronger than gravity castings.

Reduced Stress Concentration

Porosity, acting as stress concentration points, can weaken mechanical properties. Vacuum die-casting mitigates this risk by reducing porosity.

Haichen produce vacuum machine for die casting machines for more than 10 years. It has various vacuum series to meet complex die casting production. With rich experience of this line. Haichen can supply suitable vacuum machine according to customer’s specific die casting production requirement. With Haichen’s vacuum machine, it can improve your die casting productivity and efficiency.

Improve production efficiency and reduce energy consumption

- Shortened Production Cycle

- Improved Product Yield and Reduced Rework

Vacuum die casting technology can achieve rapid exhaust and efficient filling by optimizing mold design and process parameters, thereby improving production efficiency.

Moreover, vacuum die casting systems usually adopt centralized air supply. That reduces the footprint of each die casting machine and improves the stability and reliability of the system.

Shortened Production Cycle of die casting vacuum machine advantages

- Vacuum die casting significantly accelerates molten metal flow by rapidly filling the mold and reducing cavity back pressure, shortening filling and cooling times.

- This reduces the need for post-processing (such as repairing pores or surface defects), directly shortening overall production cycle time.

Improved Product Yield and Reduced Rework

A vacuum environment effectively eliminates defects such as porosity and shrinkage, reducing scrap rates. It is clearly stated that vacuum die casting can reduce scrap rates, directly increasing effective production capacity.

Computer simulation combined with vacuum technology (such as the FV method) can predict defects, optimize mold design, and reduce trial and error time.

Suitable for the production of complex thin-walled parts

- Core Capabilities for Achieving Thin-Wall Structures

- Improved molding quality for complex geometries

Vacuum machine for die casting is particularly suitable for the production of complex thin-walled parts with high strength and high toughness.

Such as automobile chassis suspension and gearbox body. These parts usually require high precision and surface finish, and vacuum die-casting technology can meet these requirements.

Core Capabilities for Achieving Thin-Wall Structures

Vacuum die casting significantly improves the fluidity of the molten metal by eliminating gas within the mold cavity, enabling the melt to evenly fill the fine details of complex molds.

Improved molding quality for complex geometries

The vacuum environment reduces gas resistance during melt filling, allowing the metal to flow more easily into complex areas such as narrow, deep cavities, and chamfers, ensuring clear contours and complete details.

Reduce equipment investment and operating costs

- Reduced Scrap and Material Waste

- Reduced Post-Processing Costs

- Optimize equipment utilization and lifespan

For example, by sharing a large volume high vacuum chamber, a large amount of investment can be saved. Moreover, the casting yield can reach more than 90%, it has significant economic benefits.

Reduced Scrap and Material Waste

Vacuum die casting eliminates air from the mold cavity, significantly reducing casting porosity and surface defects (such as bubbles and pinholes), thereby significantly reducing scrap rates.

Reduced Post-Processing Costs of die casting vacuum machine advantages

The improved surface quality of vacuum die-cast parts is noted to “significantly improve surface finish and reduce finishing costs.” It also mentions that compared to silica sol casting, vacuum die-casting “significantly reduces surface defects and may eliminate the need for major surface treatment processes.”

Optimize equipment utilization and lifespan

Reduced equipment pressure: Vacuum die casting uses 30% to 50% lower filling pressure than conventional die casting. This reduces punch pressure and extends mold and machine life, thereby reducing equipment maintenance and replacement costs.

The Combined Benefits of Integrated Vacuum die casting machine

HAICHEN not only provides high-performance vacuum machines for die casting machines but also deeply integrates and optimizes them with its own hot chamber machines. This creates a unique technical solution.

Customer’s Quality Problem

A maker of high-end zinc alloy hardware needed strict plating and salt spray tests.They have long been troubled by internal micro-pores causing plating blistering and substandard corrosion resistance.

HAICHEN’s Integrated Solution and Machine Selling Points

HAICHEN provided a hot chamber die casting machine with an integrated high-efficiency vacuum system. This solution shows these combined selling points:

- Efficient and Stable Vacuum System: HAICHEN’s system uses a high-flow vacuum valve and optimized piping. It removes air faster and keeps the vacuum level more stable. This ensures the best low-pressure environment for metal filling every shot.

- Seamless Sync with the Injection Process: The start and stop of the vacuum system sync perfectly with the machine’s injection profile in the control system. This deep integration avoids the delays or interference that external add-on systems might have. Process repeatability is excellent.

- Performance of the Hot Chamber Machine Itself: Combined with HAICHEN hot chamber machine’s own high-precision injection control and stable furnace temperature management, the zinc alloy fills the cavity in the best way under vacuum. This brings out the full potential of both the material and the vacuum advantage.

Results and Value Created

After using this integrated solution, internal pores in the customer’s castings were mostly gone. The plating yield rate jumped from 85% to over 98%. The salt spray test time was much longer. Also, because the scrap rate went down and mold protection was better, the total production cost dropped significantly.

Haichen die casting vacuum machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features. Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

Die casting vacuum machine has become an indispensable part of the modern die-casting process. It with advantages of improving the quality of castings, optimizing production efficiency, improving appearance quality and reducing production costs.