Materials used in heat treatment, such as aluminum, zinc,copper alloys, and steel, are treated to improve strength and durability.

The process of die casting always involves subjecting the casting to mechanical stress to obtain refined properties and increased durability.

In order to improve the die’s impact resistance and intergranular cracking along with maintaining its structural integrity, alloys undergo a series of hot working cycles followed by annealing and claim processes.

Corrosion infiltration treatment and wet etch process is done to boost aluminum’s rigidity enhancing properties.

Ceramics and other non metals can also be subjected to certain thermal processes such as coating the surface of a component with ceramic for improved wear tolerance.

This is an integral process when the specific material design requires distinct details or tailored attributes, especially when considering the thermal effects on the materials microstructure.

Materials used in heat treatment

The table below depicts the materials used in combination with the desired techniques for die casting and corresponding heat treatments.

- Aluminum Alloys

- Zinc Alloys

- Magnesium Alloys

- Copper Alloys

- Steel

Aluminum Alloys

Aluminium die cast alloys are frequently used alloys in die casting due to their lightweight nature and high strength. Heat treatment of aluminium alloys consists of processes such as solution heat treatment which involves dissolving alloying elements and artificial aging which increases strength.

Zinc Alloys

Zinc alloys are also utilized in die casting owing to their good mechanical properties in addition to exceptional castability. Heat treatment of zinc alloys routinely involves aging, which greatly enhances strength and hardness.

Magnesium Alloys

Magnesium alloys are chosen owing to their low density but experience high strength per unit weight. Heat treatment of magnesium alloys often includes solutions and aging processes which improve the mechanical properties of the alloy.

Copper Alloys

Copper alloys like brass and bronze have enormous strength and corrosion resistance. And is used in die casting because of their superb thermal and electric conductivity. Treatment of copper alloys under elevated temperatures may include to soften the material. Thereby improving the formability to increase the alloy ductility.

Steel

Steel is used in die casting as it posses high strength and wear resistance. The heat treatment processes for steel include normalizing, annealing, quenching and tempering which is done to obtain a certain strength and toughness and controlled hardness.

Importance of Heat Treatment of Die Casting Components

Castings tend to have lower mechanical properties like strength, hardness, and even toughness. To remedy this issue, heat treatment is indispensably critical in the die casting process. This becomes more important in components that endure substantial mechanical stress and wear during their service life.

A more handy example would be the automotive industry where numerous. And complex engine parts are first manufactured by die casting. And are subsequently heat treated as they require high levels of reliability and performance.

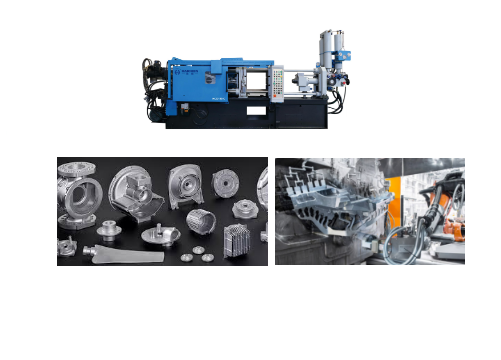

A set of advanced die casting machines was supplied by Haichen in 2020 to one of the Thailand based companies in the automotive industry. This company primarily deals with the manufacturing of high precision Automotive engine cylinder blocks and cylinder heads. Which, during operation, requires the component to sustain severe levels of temperature and pressure. The application of die casting machines from Haichen has enabled this company to automate. And refine process control with guaranteed quality of the castings. Further value added processes through heat treatment is part of the production process to increase the mechanical properties further for compliance with automobile engine requirements.

This fully incorporates the significant impact that heat treatment of die casted components has. And the exemplary performance of the Haichen die casting machines during the operations.

Selection of heat-treated materials

Different materials have different properties and react differently to heat treatment processes. Therefore, it is important to select the material that best suits the application requirements.

Take for instance high carbon steel. It is the most common material for making railway spikes because of the need for extreme hardness and wear resistance. Spikes must endure high stress and frequent friction during use. Therefore a great deal of quenching and tempering to increase hardness and wear resistance is done after functionalizing the dies.

Something like the housing of outdoor lighting fixtures requires the panels to be lightweight and corrosion resistant. Thus aluminum alloys are used. Having lesser weight, aluminum alloys can have their strength. As well as corrosion resistance enhanced if proper heat treatment like solution treatment or aging hardening is done, making them suitable for outdoor products.

Haichen’s Role in Die Casting Heat Treatment

At Haichen, we focus on the manufacturing of advanced die-casting machines designed to suit the needs of every client’s requirement of heat treating differing materials. We provide our machines with the capability of precise temperature control and unmachined uniform distribution of heating. These factors are fundamental to achieving the required mechanical properties of aluminum, zinc, and other alloys.

Advances in Technology Integration

Haichen automates the die casting solutions, implements advanced technologies, which streamlines the processes and cuts down the costs.

This enhances the heat treatment procedure alongside the quality and reliability of the final products.

Maximal Optimal Outcomes Obtained Using Heat Treatment

Haichen guarantees optimal heat treatment for the machines, making them desirable to manufacturers who aim to refine their heat treatment processes.

Equipped with Haichen technology, manufacturers can obtain far better results concerning the components which need to undergo precise thermal treatment during production.

HAICHEN’s Real-World Application Case

A die-casting manufacturer producing large aluminum alloy structural parts for the automotive industry faced a significant challenge when using HAICHEN’s 880-ton cold chamber die-casting machine: the core mold inserts (especially the core and sliders) used to form complex thin-walled structures began to show early signs of thermal fatigue cracking and slight plastic deformation after approximately 15,000 cycles of production. This led to increased burrs and dimensional deviations in the castings, and frequent mold repairs severely disrupted production schedules and increased costs.

HAICHEN’s Solution

After analysis, the HAICHEN technical team determined that the root cause of the problem was that the heat treatment process of the mold material did not fully match the characteristics of the high-cycle thermal load of the part. The customer’s original mold used general-purpose H13 (4Cr5MoSiV1) hot work tool steel, but its toughness and thermal stability after heat treatment were insufficient.

Material Upgrade Recommendation

HAICHEN recommended upgrading the critical inserts subjected to the highest impact and thermal loads to high-quality pre-hardened H13 steel, or using high-end materials with higher thermal fatigue resistance such as Dievar (from Uddeholm, Sweden) or HD (an improved domestic version). These materials, through purer metallurgical processes and micro-alloying, significantly improve toughness, thermal conductivity, and resistance to tempering softening while maintaining high hardness.

Application Results

After implementing the material and heat treatment optimization, the service life of the critical mold inserts was significantly improved.Under the same HAICHEN die-casting machine and production parameters, the service life of the mold inserts was significantly extended. They reached over 35,000 production cycles before showing signs of thermal fatigue requiring maintenance. This represents a lifespan increase of more than 130%.

Concurrently, issues related to casting dimensional fluctuations and burrs caused by mold deformation were substantially reduced. This improvement ensured higher production stability and overall yield.

As a result, the mold cost allocated to each unit product was effectively lowered for the customer. This outcome clearly demonstrates the core value of applying precise materials science and heat treatment processes in high-end die-casting production.

A certain set of materials is chosen in regard to the properties which are expected from a die casting heat treatment part.

The materials like: aluminum, zinc, magnesium, and copper alloyed steel, including other steels are selected in regard to their thermal processing capabilities.

Each material is subjected to a unique heat treatment process and the aim is to provide the right amount of strength, ductility, and stability to the geometry of the component.