Die casting heat treating types mainly includes 7 types like annealing treatment, aging treatment, T6/T7 heat treatment and so on.

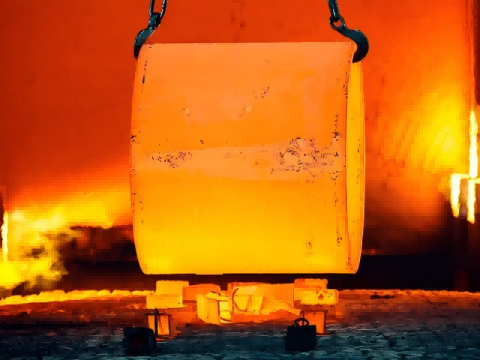

Die Casting is an advanced procedure. It involves the injection of molten metal into a cavity mold under high pressure, which makes it possible to manufacture uniquely complex parts with great detail. This method is helpful in the aerospace and automotive industries because of the greater operational productivity and efficiency it provides.

For increasing productivity, the die casting heat treatment processes should focus on the thermal treatment of the components’ structure. Such as improving the strength of the casting and extending the die life. For best results, castings should be treated with T5/T6/Auraltherm. Molds need more thermal fatigue resistant alloys, which require surface-strengthening or pre-treat nitriding. Lower iron aluminum alloys as new materials provide better treatment options when controlling the cooling and decomposition rates during solution holding.

There are many types of heat treatment of die casting. And the specific heat treatment method selected depends on the type of material, the required mechanical properties and the application. They mainly include 7 types like annealing and aging treatments, T6/T7 heat treatments, and so on. Details will be elaborated like below:

- annealing treatment

- solution treatment

- aging treatment

- Hot and cold cycle treatment

- T6 heat treatment

- T7 heat treatment

- Surface strengthening treatment

Die casting heat treating annealing treatment

Heat the die casting to about 300℃, keep it warm. And then it will cool it to room temperature in the furnace to eliminate these aspects. Such as internal stress, stabilize the size, reduce deformation and enhance plasticity.

core purpose

- Stress relief: Relieve residual stress during machining or cooling processes.

- Improve plasticity: reduce hardness and improve subsequent forming or cutting performance.

- Stable size: reduce the risk of deformation during long-term use.

Specific process annealing of castings

- Aluminum alloy: Keep at 280-300 ° C for 2-3 hours, then cool slowly in the furnace to room temperature to decompose the solid solution and precipitate a second phase.

- Mold steel: Annealing at around 800 ° C for 1-2 hours, slow cooling to avoid cracking.

- Special annealing type:

- Spheroidization annealing: used for tool steel to transform layered carbides into spherical shapes and reduce hardness.

- Recrystallization annealing: repairing lattice distortion after cold processing and restoring ductility

solution treatment

Heat the die casting to a temperature close to the melting point of the eutectic. After keeping it for a sufficient time and then cool it down to fully dissolve the components and improve the strength, plasticity and corrosion resistance. The effect of solution treatment is affected by temperature, holding time and cooling rate.

The main purpose of Die casting heat treatment

- Improve mechanical performance: significantly enhance the mechanical strength, fatigue strength, and impact toughness of die-casting parts through heat treatment.

- Improve dimensional stability: eliminate casting and processing stresses to make the dimensions of die castings more stable.

- Improve machining performance: Improve cutting and welding performance to make subsequent machining easier.

- Improve corrosion resistance: Improve the corrosion resistance of materials through precipitation hardening.

Typical process parameters for solution treatment

In die casting, solution heat treatment is a key step in the heat treatment process. It aims to dissolve the strengthening phase in the alloy through heating. Forming a supersaturated solid solution and providing a basis for subsequent artificial aging treatment.

Temperature range

The temperature of solid solution treatment is usually close to or slightly higher than the eutectic temperature of the alloy. Then to ensure that the strengthening elements (such as Mg, Si, Cu, etc.) in the alloy are fully dissolved. For common die cast aluminum alloys such as ADC12, A356, etc., the solution treatment temperature is generally between 480 ° C and 540 ° C.

Time

The time for solution treatment depends on the type of alloy. At the same time together with the thickness of the casting, and the uniformity of the microstructure. Usually, the solid solution treatment time is between 0.25 hours and 2 hours. But in some cases, a longer time (such as 4-12 hours) may require to ensure complete dissolution of the strengthening phase. For example, the solution treatment time for ADC12 alloy is usually 1-2 hours. For A356 alloy, the recommended solution treatment time is 4 hours.

Cooling method

After solid solution treatment, rapid cooling (such as water cooling or air cooling) usually use to retain the supersaturated solid solution. And also prevent the re-precipitation of strengthening phases. Rapid cooling can effectively improve the strength and hardness of alloys.

aging treatment

In the die-casting process, aging treatment is a heat treatment process. It main purpose is to stabilize the alloy structure by controlling the decomposition of supersaturated solid solutions in the alloy. Thereby improving the mechanical properties and structural stability of the material.

FunctionImproving mechanical properties

Aging treatment significantly enhances the strength and hardness of the alloy by precipitating second phases such as Mg2Si, Al8Mg3FeSi6, etc. For example, A356 aluminum alloy reaches its peak tensile strength and hardness after 9 hours of aging treatment.

Stable organizational structure

The precipitated second phase particles are uniformly distributed at grain boundaries and within the grains. It helps to stabilize the microstructure of the alloy. While reducing dislocation motion during deformation. Thus improve the dimensional stability and fatigue resistance of the material.

Improving thermal performance

The precipitated second phase can reduce lattice distortion, increase electron mobility, and enhance the thermal conductivity of the alloy. For example, A356 aluminum alloy has significantly improved thermal conductivity after 9-12 hours of aging treatment.

Eliminating casting stress

During the die-casting process, significant residual stresses are generated inside the casting. Aging treatment can effectively alleviate these stresses, improve the dimensional stability and deformation resistance of the casting.

Optimizing processing performance

Aging treatment can improve the work hardening ability of alloys by precipitating second phases. Making them more suitable for subsequent mechanical processing and surface treatment.

Hot and cold cycle treatment

Hot cycle treatment definition and purpose

Thermal cycling treatment adjusts the microstructure of materials through multiple heating and cooling cycles, thereby improving the dimensional stability, stress relief, and mechanical properties of die castings. The core principle is to utilize the periodic expansion and contraction of the solid solution lattice to promote the redistribution of second phase particles to a more stable state.

Typical process flow

- Application case of aluminum alloy die-casting parts (precision thin-walled parts):

- First stabilization time: After rough processing, heat to 250-290 ℃, hold for 2-4 hours, and air cool;

- Second stabilization aging: After semi precision processing, heat to 250-290 ℃, hold for 1-2 hours, and then perform thermal cycling treatment;

- Thermal cycling steps: Place the workpiece in a low-temperature container at -70~-50 ℃ for 1-2 hours, and then return to room temperature.

General process

Heat to the predetermined temperature (such as 250~500 ℃, depending on the material), and keep warm uniformly; Cooling at a set rate in air/liquid medium; Repeat 2-3 times to optimize the effect.

Performance improvement mechanism

- Dimensional stability: Thermal expansion/contraction causes lattice displacement, reduces residual stress, and prevents deformation during service.

- Mechanical properties: Dissolve strengthening phases at high temperatures, precipitate fine particles during cooling, and improve strength and toughness.

- Corrosion resistance: homogenize the microstructure and reduce the tendency of electrochemical corrosion.

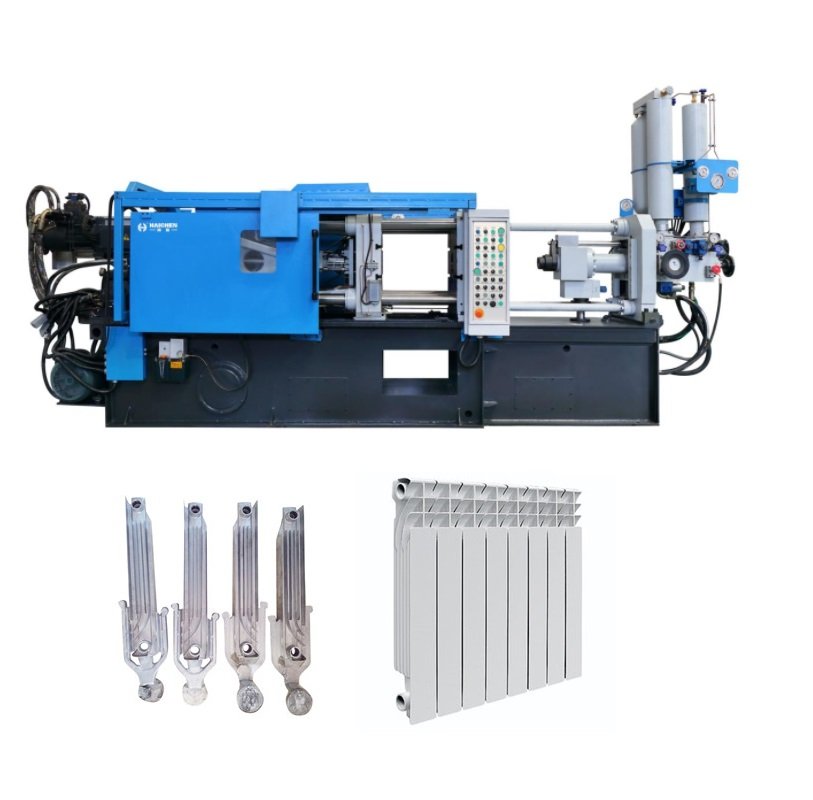

HAICHEN Die Casting Heat Treating Types in Practice

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

HAICHEN is one Chinese understands how heat treating integrates with die casting production.

- Heat Treated Aluminum Pot Handle (T5)

- Aluminum Heater Body with Stress Relief

- High-Strength Aluminum Road Stud (T6)

Heat Treated Aluminum Pot Handle (T5)

During HAICHEN machine castting the aluminum pot handles. These handles receive a T5 aging treatment. This improves their strength without complex steps. The handles stay strong when lifting heavy pots. They also resist bending during use.

Aluminum Heater Body with Stress Relief

Haichen casts aluminium radiator heater body, these large parts undergo stress relieving. This ensures they stay flat and do not warp from heat cycles. It is vital for maintaining proper fit and seal in the heating system.

High-Strength Aluminum Road Stud (T6)

To produce aluminium road studs, HAICHEN casting followed by full T6 treatment. The solution heat treatment and aging create a very strong part. This stud can withstand truck weight and harsh weather for years.

Heat treating is a powerful tool to enhance die cast parts. Different die casting heat treating types serve different needs, from simple aging to high-strength cycles. The choice depends on the part’s function. HAICHEN provides the precision die casting machines that produce parts ready for these treatments. By combining good casting with the right heat treatment, manufacturers can make superior products like durable pot handles, stable heater bodies, and strong road studs.

T6 heat treatment

Definition of T6 Heat Treatment

T6 heat treatment is a heat treatment process for aluminum alloys, defined as the state of artificial aging after solution treatment. This process involves heating aluminum alloy to a high-temperature single-phase zone to fully dissolve the alloy elements into the solid solution, followed by rapid cooling (quenching) to form a supersaturated solid solution. Then, through artificial aging treatment at higher temperatures and longer holding times, the precipitated phases in the alloy are uniformly precipitated, significantly improving the strength and hardness of the material.

Specific process steps and parameters

T6 heat treatment is a common aluminum alloy heat treatment process, which mainly includes three steps: solution treatment, quenching, and artificial aging. The following are the specific process steps and parameters:

Solution treatment

Aluminum alloy is heated to high temperatures (usually 480-535 ℃) to fully dissolve the alloying elements into the matrix, forming a uniform solid solution. The insulation time depends on the material and process requirements, usually 1-6 hours.

quench

The workpiece after solution treatment is rapidly cooled (usually using water or oil) to fix the position of solutes in the solid solution and prevent their precipitation. The quenching time usually does not exceed 15 seconds to ensure rapid cooling.

Artificial efficiency

After quenching, the workpiece is kept at a lower temperature (usually 150-190 ℃) for a period of time (usually 4-8 hours) to allow alloy elements to precipitate from the solid solution, forming strengthening phases, thereby improving the strength and hardness of the material

T7 heat treatment

Definition and purpose of T7 heat treatment

T7 heat treatment is a heat treatment process for aluminum alloys, whose main purpose is to improve the material’s dimensional stability, corrosion resistance (especially stress corrosion cracking resistance), and mechanical properties through solution treatment and over aging treatment (or stabilization tempering).

T7 heat treatment steps

- Solution treatment: Heat the aluminum alloy to a high temperature (such as 500-540 ° C) and hold it for a period of time to fully dissolve the alloy elements into the solid solution, then rapidly cool it (such as air-cooled or water-cooled) to form a supersaturated solid solution.

- Over aging treatment: After solid solution treatment, the material is heated to a temperature slightly higher than the working temperature (such as 190-225 ° C) and held for a period of time to precipitate an appropriate amount of strengthening phase, thereby improving the stability and corrosion resistance of the material.

Surface strengthening treatment

Definition

Surface strengthening treatment is a technique that improves the surface hardness, wear resistance, and fatigue resistance of materials by altering their microstructure and chemical composition. Its main purpose is to enhance the performance of the mold surface without sacrificing the strength and toughness of the mold core.

Common surface strengthening treatment methods

- (1) Chemical heat treatment

Chemical heat treatment is the process of heating a mold in a medium containing active elements (such as carbon, nitrogen, boron, etc.) to allow these elements to infiltrate the surface of the mold, thereby altering its surface chemical composition and microstructure. - (2) High-energy beam surface strengthening

High energy beam surface strengthening technology utilizes high-energy beams (such as lasers and electron beams) to rapidly heat and cool the mold surface, thereby forming a hardened layer. - (3) Physical or Chemical Vapor Deposition (PVD/CVD)

Physical or chemical vapor deposition technology improves the surface hardness and wear resistance of molds by depositing a protective coating on their surface. - (4) Electric brush plating

Electric brush plating is a technique of depositing metal coatings on the surface of molds through electrochemical methods. This method can quickly repair the damage on the surface of the mold and improve its surface hardness and wear resistance.

We can see, above these heat treatment methods significantly improve the mechanical properties, corrosion resistance and dimensional stability of die castings by changing their microstructure and organization, thereby extending the service life of die castings and improving their processing quality.