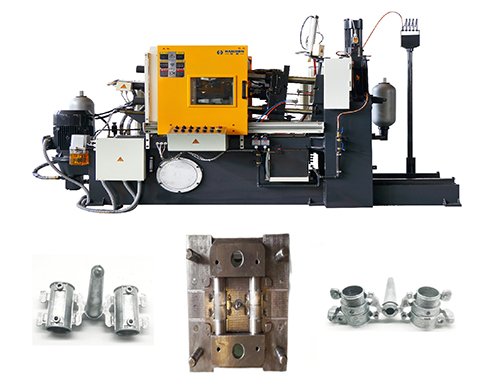

Zinc pipe fitting production line mainly includes raw material, mould and hot chamber die casting machine.

The use of hot chamber die casting machine in the production of zinc pipe fittings is a common manufacturing process. This process is suitable for low melting point metals such as zinc, tin, and lead. The working principle of a hot chamber die casting machine is to maintain the molten metal at an appropriate temperature and inject the metal into the mold through a metal pump (called a “gooseneck”) immersed in the molten metal. This process can achieve high productivity and high-quality castings.

The zinc pipe fitting production line is a complex and highly integrated system. It covers every link from raw material processing to finished product. The following is a detailed description of the zinc pipe production line:

Raw material

Zinc pipe fitting Mold

Die casting machine

Raw material preparation

In the zinc pipe joint production line, raw material preparation is the fundamental link of the entire production process, and its quality and efficiency directly affect the smooth progress of subsequent processing steps.

Firstly, The preparation of zinc pipe fitting includes selecting appropriate sizes and specifications, and ensuring that their surfaces are smooth, without bending or damage.

Secondly, the zinc alloy ingot is fed into the die casting machine for melting. Usually electric heating or natural gas heating is used to heat the zinc alloy to about 450°C to ensure its fluidity.

Mold preparation of zinc pipe fitting production line

- selection of mold materials

- mould design

- mold preparation steps

- Processing and Manufacturing of Molds

The preparation of molds for the production line of zinc pipe fittings is a key link in the entire production process, and its quality directly affects the accuracy and performance of the final product.

Selection of mold materials

Zinc alloy die-casting molds are usually made of high carbon steel or alloy steel to ensure the strength and durability of the mold under high temperature and high pressure. The material of the mold needs to have good thermal stability and wear resistance to adapt to the casting process of zinc alloy in a molten state. In addition, surface treatment of molds (such as chrome plating and polishing) is also an important factor in improving mold life and product quality.

Mould design

The design of molds requires precise calculations based on product shape and process requirements. A mold usually consists of two parts: a cavity and a core, which are connected by a parting surface. The design of molds not only needs to consider the geometric shape of the product, but also the design of auxiliary structures such as pouring system, cooling system, exhaust system, etc. For example, the design of the cooling system is particularly important for zinc alloy die-casting molds, as the cooling effect directly affects the dimensional accuracy and surface quality of the castings.

Mold preparation steps

Mold preheating: Before die-casting, the mold usually needs to be preheated to a certain temperature to reduce the thermal stress between the mold and the zinc alloy, and prevent mold deformation or cracking.

- Mold cleaning: The mold needs to be thoroughly cleaned before use to remove surface oil stains, oxides, or other impurities to ensure smooth pouring of zinc alloy and good surface quality.

- Mold lubrication: In order to facilitate the demolding of castings, the inner surface of the mold is usually coated with a layer of demolding agent (such as graphite or water-based demolding agent) to reduce the friction between the casting and the mold.

- Mold closure: The mold needs to be precisely closed before die-casting to ensure good fit between the cavity and core, and to avoid porosity or inclusion defects during the pouring process.

Processing and Manufacturing of Molds

The manufacturing of molds usually includes the following steps:

- Model making: Use CAD software to design a three-dimensional model of the mold, and create a prototype of the mold through 3D printing or CNC machining.

- Mold casting: The prototype of the mold is used to cast the outer shell of the mold, usually using zinc alloy or plastic casting.

- Mold processing: Further processing of the cast mold, such as milling, drilling, electrical discharge machining (EDM), etc., to achieve the required accuracy and surface quality.

- Mold assembly: Assemble the processed mold components into a complete mold and debug it to ensure its performance during the die-casting process

Before die casting, the mold needs to be cleaned and lubricated to facilitate better demolding after cooling. The design and manufacture of molds are important parts of the die casting process because they determine the shape and precision of the product.

Die casting

- Basic process of die-casting technology

- The die-casting process includes the following main stages

Basic process of die-casting technology

The core of die-casting technology is to inject molten metal into the mold under high pressure, causing it to solidify and form the desired shape inside the mold. Zinc alloy is particularly suitable for die-casting production due to its low melting point, good fluidity, and high ductility. The die-casting of zinc alloy usually uses a hot chamber die-casting machine because of its low melting point, which is suitable for directly injecting molten metal into the hot chamber

The die-casting process includes the following main stages

- Mold closure: The mold is closed under high pressure, ready to receive molten metal.

- Molten metal injection: Molten metal is injected into the mold cavity through the gating system of the mold.

- Pressure holding and cooling: The metal is kept under high pressure in the mold until it is completely solidified, and then the mold is opened and the casting is pushed out.

- Cooling and treatment: After the casting is taken out of the mold, it is cooled and surface treated, such as polishing, electroplating, etc.

The molten zinc alloy is injected into the mold cavity through the injection mechanism. Under high pressure, the molten metal quickly fills the mold and solidifies after cooling. This process usually requires precise control of temperature and pressure to avoid defects such as pores, shrinkage, etc.

Cooling and demoulding

- Cooling process

- Demolding process

cooling process

Cooling is a crucial step in the production process of zinc pipe joints. According to, the temperature distribution of cooling pipes is influenced by various factors, including the flow rate of cooling water and the width of the cooling pipes. Research has shown that the temperature of cooling pipes varies greatly in the radial direction and gradually decreases in the axial direction. In addition, the width of the cooling duct has a complex impact on temperature distribution, and there exists an optimal width range. Therefore, when designing a cooling system, the flow rate of cooling water and the width of cooling pipes should be optimized according to specific operating conditions to ensure uniform temperature distribution and avoid zinc layer defects or material deformation caused by excessive temperature differences.

Demolding process

Demolding is another key step in the production of zinc pipe joints. A demolding device for large pipe fittings, including a fixed mold cavity, a movable mold core, and a hydraulic cylinder, can effectively solve the problem of uneven temperature during the forming process of large-sized pipe fittings, improve product quality, and shorten production cycles.

The die-casting casting needs to be cooled before the mold can be opened and taken out. Some production lines use forced cooling technology to speed up this process.

Post-processing

The removed castings usually need to undergo a series of post-processing steps, including deburring, polishing, electroplating or powder spraying, etc., to improve the surface quality and durability of the product.

Modern zinc pipe fitting production line may also uses automation technologies such as PLC control systems and robotics to improve product quality and efficiency. The application of these technologies makes the production line more flexible and efficient, able to meet the needs of large-scale production.

Haichen zinc pipe fitting die casting making machine

HAICHEN Zinc Pipe Fitting line with Hot Chamber Technology

HAICHEN provides highly reliable core equipment and solutions for zinc pipe fitting production lines. It uses hot chamber machines made for zinc alloy and deep process know-how.

Customer Production Challenge

A pipe fitting maker had a low yield rate for high-end zinc alloy valves. Their products showed unstable sealing in high-pressure tests. Also, machining often exposed pores in the threaded areas.

HAICHEN Hot Chamber Machine Solution and Selling Points

HAICHEN offered a high-performance hot chamber machine and process optimization. Its key selling points directly solved these problems:

- High Precision and Stability: The machine uses a closed-loop control system. This keeps injection speed and pressure very stable every time. It ensures consistent size and weight for each rough casting, which is key for precise threads.

- Excellent Filling and Venting: The optimized injection system works with an optional mold vacuum. This lets the zinc alloy fill complex mold cavities smoothly and quickly. It greatly reduces trapped air and improves casting density, which directly fixes leak-proof issues.

- High Efficiency and Low Waste: The injection mechanism of HAICHEN’s hot chamber machine sits in the melt. This reduces heat loss and allows fast cycle times. It is perfect for high-volume, efficient production of zinc pipe fittings. It also saves energy and material.

Haichen advantages

After using the HAICHEN machine and process, the customer’s valve yield rate improved a lot. The pass rate for high-pressure tests went over 99.5%. Because the rough castings were better inside, the scrap rate in later machining also dropped. Overall production cost was better controlled, making the customer more competitive.

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features. Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We have rich experience of producing zinc pipe fittings making machine as per each customer’s specific demand. Futhermore, we can also supply suitable full production line.