Choosing an aluminum casting manufacturer involves evaluating quality, expertise, certifications, and technical capabilities, among other things.

When selecting an aluminum casting manufacturer, assess their casting particular industry experience. Relevant industry certifications (such as ISO 9001). How far they can customize, production capabilities, soft skills, compliance, reputation, etc. Analyze quotes to check for value vs quality.

The text below will discuss how to select the caster servicing your needs tailored to the specific requirements factors. That guarantee high quality products through all the given explanations.

How to select aluminium casting manufacturers?

This guide serves to assist you in making the right decision when selecting an aluminium casting manufacturer.

- Quality Assurance

- Technical Expertise

- Certifications and Standards

- Production Capacity and Flexibility

- Customer Service and Support

Quality Assurance

Give priority to quality. Target manufacturers who have been in business and specialize in the production of cast aluminum parts of high quality grade. They should be able to prove that they do have and enforce ample control of quality processes. That ensures their product/service reliability.

Technical Expertise

Select a manufacturer that has wide information and experience in aluminum casting with the ability to do broad scope work. They should be capable and have the resources to handle difficult tasks. And handle various projects at the same time with different aluminum alloys.

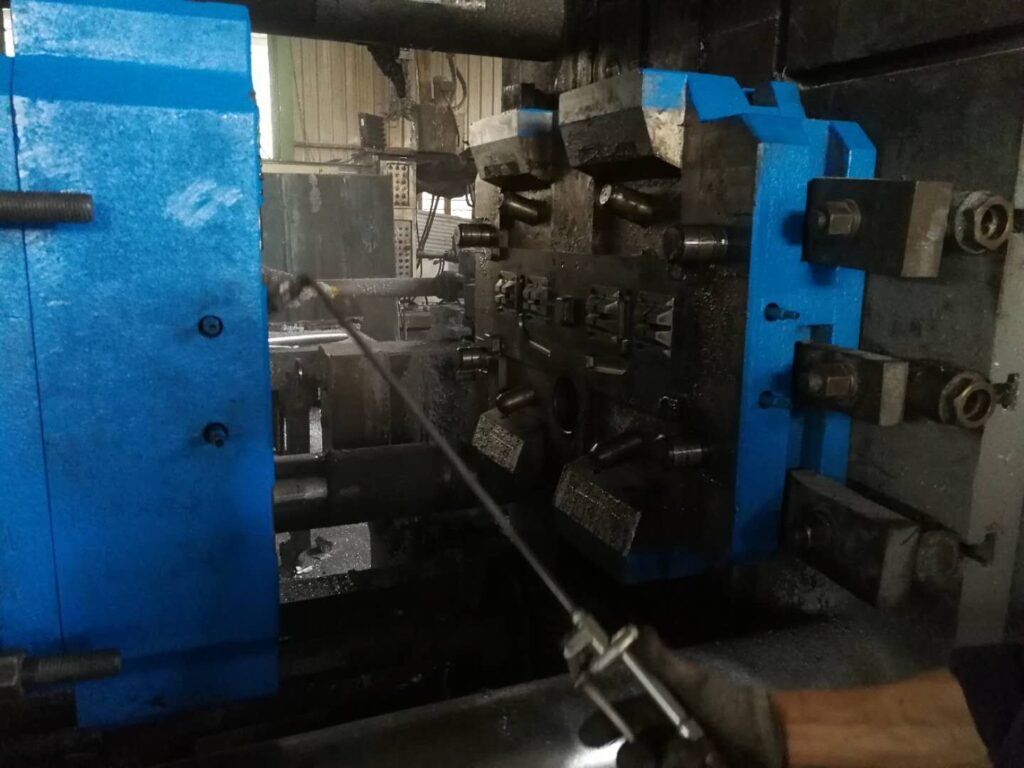

Furthermore, they should know other casting techniques like die casting which involves the precision reproduction of an item. This requires the manufacturer to have high quality equipment.

Other activities the manufacturer has to engage in include the other alloys of aluminum which are important for some the project requirements and so that band of work.

It helps a lot if such a supplier is willing to put together some of the documentation illustrating the results of their skillful execution of other projects for different clients.

Certifications and Standards

Make sure that the supplier has industrial and eco-friendly certifications like ISO 9001 and ISO 14001. This demonstrates the company’s attempt towards preservation and reduction of impacts processes.

Such certified Manufacturers have documented proven quality assurance systems in place and are reliable to maintain and improve performance while mitigating negative environmental impacts.

Production Capacity and Flexibility

Evaluate the supplier’s production capacity and flexibility. They must accommodate both high volume and low volume orders with the ability to increase or decrease production as required.

HAICHEN’s diverse production abilities have been enhanced with the addition of HDC series cold chamber die casting machines. HAICHEN has over 28 ton to 2080tons of tonnage capacity machines, that are best suited for both small and medium sized production, therefore enhancing unit and mass production.

For this 2023 year, HAICHEN casted an 880 ton cold chamber die casting machine for an aluminum alloy pot handle manufacturer. Their unparalleled capacity strategically blended with their adept production capabilities culminated in outstanding volume output during the production cycles.

With such adaptable and scalable manufacturing capacities, the these suppliers are better positioned to address your requirements without compromising quality or efficiency.

Customer Service and Support

Policies pertaining to customer service must ensure assistance for the client’s needs including timely and dependable support throughout the process.

Selecting an Aluminum Casting Manufacturer with the Mastery of HAICHEN

With all the industry experience, the selection of an aluminum casting manufacturer is straightforward and uncomplicated due to HAICHEN’s outstanding precision-grade casting machines and proprietary aluminum casting technology.

Keysteps with HAICHEN:

- Hight Precision and Quality: Recognized for unmatched or superlative dimensions quality, every part manufactured on HAICHEN machines, undergoes as unforgiving scrutiny as has ever been casted.

- Custom Solutions: Creative tailored approaches are provided as far as fulfilling small orders up to colossal bulks.

- Support and Service: Tackling problem resolution and operational challenges is child’s play with HAICHEN’s orthodox extensive post-purchase service smoke.

- Innovation: Each new change made in techwise allows the machines to be most temgacious toward give the best features for aluminum casting.

With HAICHEN’s unrivaled mastery and unmatched technology in aluminum casting, sharpening operations for any caster is easy and advantageous.

The rigorous research and quality standards set forth alongside the analysis of these aspects provide the means necessary to select an aluminum casting manufacturer that adheres to the set business mandates, objectives, and quality benchmarks.

Appropriately choosing the manufacturer strategically sets the caster toward the precision-grade aluminum castings ache types intended and long-term partnership with the manufacturer ensure nurtured growth of outcomes in preference to the castings.