Surface finish options for die casting as follows:

- Anodizing

- Increase the thickness of the oxide film

- Improves hardness

- Improves microstructure

- Sealing treatment

- Electrolyte composition and process control

- Powder coating

- Electroplate

- Mechanical polishing and grinding

- Chemical treatment

- Japanning

- Grit blasting

- Ceramic coating

Mechanical treatments are suitable for basic cleaning, chemical/electrochemical processes provide long-term protection.

And coating technology is superior in terms of versatility and environmental friendliness.

With the advancement of technology, composite treatment.

Such as laser cladding anodizing will become an important direction to improve the performance of die castings.

The surface roughness value of die-casting

The surface roughness value of die-castings varies due to various factors such as casting materials, casting processes, mold design, and finishing techniques.

Generally speaking, the surface roughness value range of die-castings is 1 to 25 micrometers (µm) or 40 to 1000 microinches (µin).

Die casting can produce a relatively smooth surface finish, with surface roughness values typically ranging from 4 to 8 µm (160 to 320 µin).

However, in some cases, a surface roughness value as high as 25 µm (1000 µin) may also be acceptable or even ideal, depending on the specific application and requirements.

Surface for Die Casting

This is an electrochemical treatment process that improves corrosion resistance and hardness by forming an oxide film on the surface of a die casting.

Anodizing can provide a glossy or matte finish,among Haichen‘s production cases, there are those involving the subsequent polishing of die-cast parts, such as MEDALS, etc.

Increase the thickness of the oxide film

In the anodizing process, the thickness of the oxide film can be adjusted, usually up to 20-30 microns.

And even increased to more than 100 microns in special processes.

The increase in the thickness of the oxide film significantly improves the corrosion resistance and wear resistance of aluminum alloys.

Improves hardness

Alumina (corundum) is very hard, reaching 9 on a molar hardness scale, second only to diamond.

Therefore, as the thickness of the oxide film increases, the overall hardness of the die casting is also significantly improved.

Improves microstructure

Anodizing alters the microscopic texture of the surface of the aluminum alloy and the near-surface crystal structure of the metal, making it harder and has better adhesion than pure aluminum.

Sealing treatment

Sealing the hole after anodizing can further enhance the corrosion resistance and stability of the oxide film, while imparting a special gloss or color effect.

Electrolyte composition and process control

By precisely controlling parameters such as electrolyte composition, temperature.

And current density, oxide thickness and hardness requirements can be met to optimize the performance of die castings.

Powder coating

This treatment uses a dry powder material to be sprayed onto the surface of a die casting.

Which is then heat-cured to create a durable and non-flaking coating.

Powder coatings are available in a variety of colors and textures to provide good appearance and protection.

Electroplate

Including chrome plating, nickel plating, etc., through the electrochemical process on the surface of the die casting coated with a layer of metal film.

Plating can improve the appearance, corrosion resistance, and hardness of parts.

Mechanical polishing and grinding

Remove surface defects by physical means to make the surface of the die casting smooth.

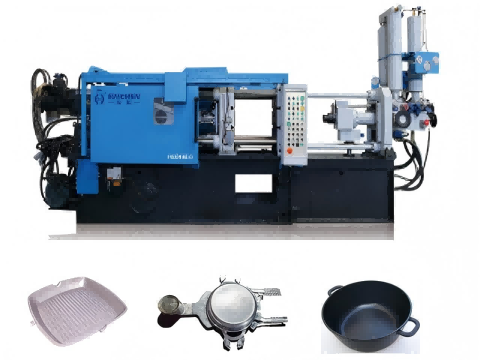

After the die-castings are demolded, Haichen will always grind or polish them, mainly to remove burrs and so on.

Chemical treatment

Including etching, phosphating, etc., these treatments can improve the adhesion of the coating and provide additional protection against corrosion.

Japanning

Liquid coatings can improve the appearance of die castings and provide additional protection against corrosion and wear.

The cost of painting is relatively low and the color options are varied.

Grit blasting

This is a mechanical treatment method that removes surface defects by blasting sand particles at high pressure, giving the surface of the die casting a uniform matte finish.

Ceramic coating

This coating provides excellent abrasion and corrosion resistance for demanding applications.

Surface for Die Casting standards

- Surface finish standards

- International Standard

- Measurement method

Surface finish standards

There are various methods for measuring the surface finish of die castings.

And the standards vary depending on the field of application and specific requirements.

First of all, the surface finish of die castings is usually measured in terms of Ra value (arithmetic mean roughness), with a common standard range of 3.2 to 0.8 microns and even 0.4 microns.

In addition, the surface finish of aluminum alloy die castings can reach Ra6.3 or even Ra1.6.

International Standard

Bodies such as the International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME) have developed relevant standards.

Such as the ISO standard and the ASME Y14.36M standard, these standards specify different testing methods, instruments and evaluation systems.

For example, the U.S. military standard MIL-O-13830B uses two sets of numbers to indicate the size of surface defects.

Such as 40-20, with the former limiting the size of scratches and the latter limiting the size of pitting.

If you want to check Haichen’s qualifications, you can visit our official website or contact us.

Measurement method

In terms of measurement methods, the surface finish of die castings can be measured by contact method and non-contact method.

Contact methods include measuring along the surface using a stylus.

Non-contact methods include techniques such as interferometry, confocal microscopy, focal change, structured light, capacitometry, electron microscopy, and photogrammetry.

Each of these methods has its own advantages and disadvantages, and the choice should be based on specific needs and conditions.

Is surface treatment necessary for die-casting

While most castings do require a surface finish, it is not always necessary.

There have been advancements in alloys that have allowed us to provide raw castings where a finish would normally have been required.

For instance, when casting an aluminum 380 alloy, traditionally you would normally have wanted a chem film or anodizing for corrosion resistance.

With the advent of K-Alloy, we’ve been able to provide parts without an additional finish that meet or exceed the requirements of the customer’s original intent.

Therefore saving them a lot of money. There have been advancements in zinc alloys as well.

While these advancements have greatly improved our casting processes, they’re not necessarily applicable to each particular application.

We suggest talking with your die cast manufacturer or asking an engineer for more information on raw castings.

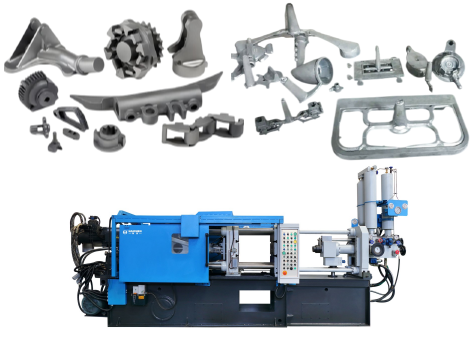

Haichen‘s experience

Different surface treatment methods are suitable for different application needs.

When choosing a surface treatment method, it is also necessary to consider the material characteristics of the die casting, the use environment, and the needs of subsequent processing.