Hot chamber die casting benefits include faster production speed, lower cost for small parts, rapid production cycle, cost-effectiveness,etc.

Hot chamber die casting offers several benefits that make it a preferred choice in various industries. Here are some of the key advantages.

Hot chamber die casting benefits

- Faster Production Speed

- Lower Cost for Small Parts

- Less Metal Wastage

- Suitable for High-Volume Production

- Enables Complex Part Casting

- Rapid Production Cycle

- Minimal Waste and Defects

- Extended Die Life

- Cost-Effectiveness

- Precision and Quality

- Versatile

Faster Production Speed:

Hot chamber die casting is known for its quick production speed, which allows for more parts to be made in less time, boosting productivity .

Lower Cost for Small Parts:

This method is cost-effective for small parts as it requires less material and energy.

Less Metal Wastage:

Hot chamber die casting uses nearly all the raw material, reducing waste and saving resources .

Suitable for High-Volume Production:

It is ideal for high-volume production, making it great for large-scale manufacturing .

Enables Complex Part Casting:

Hot chamber die casting allows for the creation of complex parts with intricate designs, offering greater flexibility in product design .

Rapid Production Cycle:

The attached melting pot within the machine’s furnace accelerates liquid metal transfer into the cavity, significantly speeding up the production cycle .

Minimal Waste and Defects:

Direct transfer of molten metal reduces waste and the likelihood of defects like blisters and porosity .

Extended Die Life:

The use of low melting point alloys extends the lifespan of the dies and machine components .

Cost-Effectiveness of hot chamber die casting benefits:

The process’s high productivity and the reduced need for a standalone furnace lower overall operational costs .

Precision and Quality:

Capable of producing parts with tight tolerances and excellent surface finishes, decreasing the need for secondary finishing .

Versatile:

Hot chamber die casting can handle a variety of metals and alloys, including zinc, magnesium, and aluminum. And it can create complex shapes and geometries that would be difficult to produce using other manufacturing processes.

What is Hot Chamber Die Casting?

Hot Chamber Die Casting (Hot Chamber Die Casting) is a highly efficient metal casting process used primarily for the production of complex geometric parts made from low melting point metals such as zinc, magnesium, lead and tin. Its core feature is that the molten metal is stored directly in the furnace inside the die casting machine, and the molten metal is injected into the mold cavity under high pressure to form the desired part.

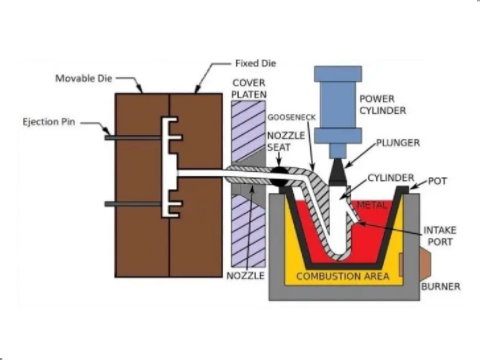

Components of Hot Chamber Die Casting

- Furnace

- Injection System

- Mold

- Ejector Pin System

- Cooling System

Furnace

The core function of the die casting machine melting furnace is to heat the metal raw material to liquid state so that it reaches a temperature suitable for injection into the mold. For example, the melting temperature of magnesium alloys is usually between 630 and 650°C, while that of zinc alloys is even lower, about 400 to 450°C.

Injection System

The injection system is the key part of the hot chamber die casting machine, including the injection cylinder (Shot Cylinder), piston (Plunger), push rod coupler (Plunger Coupler), gooseneck (Gooseneck) and nozzle (Nozzle). The shot cylinder sits above the molten metal and connects to the piston via a piston rod. When the piston moves downward, it forces the molten metal through the gooseneck and nozzle into the mold cavity.

Mold

A mold consists of an upper mold and a lower mold, and is a key component in the manufacture of parts. The cavity of the mold is designed with structures such as gates and runners to guide the molten metal to flow into and cool the molded part.

Ejector Pin System

The ejector pin system of the die-casting machine (Ejector Pin System) is an indispensable and important part of the die-casting mold, and its main function is to push out the cooled metal casting from the mold cavity. Ejector pin system usually consists of Ejector Pins, Ejector Plate and related guiding and resetting mechanism.

Cooling System

Die casting cooling system is a vital part of the die casting process, its main role is to control the temperature of the mold and casting, so as to ensure the quality of the casting, extend the life of the mold and improve production efficiency.

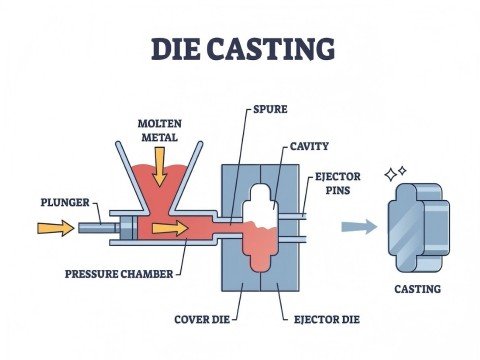

Hot Chamber Die Casting Process

- Die Preparation

- Heating of the metal

- Injection of metal

- Cooling and curing

- Mold Release & Push Out

- Demolding & Pushout

Die Preparation

The die needs to be cleaned, lubricated and assembled before die casting can begin. The mold usually consists of two halves, the fixed half and the push-out half.

Heating of the metal

The metal is heated to its melting point in a furnace inside the casting machine and then held in a molten state.

Injection of metal

A hydraulic piston pushes the molten metal from the furnace into the mold cavity through a gooseneck. This process is continuous because the furnace is directly connected to the injection system without additional metal transfer.

The process is continuous because the furnace is directly connected to the injection system and no additional metal transfer is required.

Cooling and curing

The metal is cooled and cured in the mold to form the desired part shape.

Mold Release & Push Out

The mold is opened and the metal is pushed out of the mold.

Demolding & Pushout

After the mold opening, the part removes from the mold by a pushout mechanism.

Haichen hot chamber die casting machine

Haichen is a die casting machine factory located in Ningbo, China, mainly supplying cold chamber die casting machine and hot chamber die casting machine. Besides, we also supply cold chamber die casting machine and die casting auxiliary equipments.

If there is any demand for die casting machine or other equipments, welcome to consult us.