There are several types of die casting spray nozzles, including T-Shaped Nozzles、Cross Nozzles、Y-Shaped Nozzles、Pinch Nozzles、High-Pressure Nozzles etc.

Every design aims at meeting the peculiarity of each requirement in the die casting operation so that each coverage and cooling is done appropriately.

Casting dies is a high pressure operation in which molten metal is forced under immense pressure into a cavity mold, and this process includes the use of a spray nozzle that functions as a container for pouring the molten metal into the mold.

The various categories of spray nozzles have different requirements to fulfill for optimum performance in efficiency and quality of the casting.

Different types of spray nozzle for die casting are characterized by difference in quality and speed of work done and these types are the most frequent used nozzles in die casting.

T-Shaped Nozzles

T- shaped nozzles have a central portion and a perpendicular section forming the T. While the edges have additional strokes for their design which makes separating the T without any need for alteration simple and helpful. This design makes them particularly easy to clean and maintain, reducing downtime and ensuring consistent performance.

These nozzles are widely used in cases which require a non- dispersive abrasive. And powerful spray such as in the case of lubrication or cooling in particular regions in the die casting process.

Maintenance ease and dependable performance when T – shaped nozzles are used make these devices perfect when the efficiency in die casting processes and operations needs to be retained.

Cross Nozzles

Fitted with four outlets that spray molten metal evenly across the mold cavity, Cross or cruciform nozzles do exactly that.

Turbulence is minimized so that harmonious and defect-free casting is possible, which is highly critical for balanced filling.

Each of the outlets’ symmetrical arrangements are important to guarantee a constant flow that enables effortless manufacturing of high quality tightly-toleranced components.

With their capability to minimize the chance of incomplete filling or cold shuts. Cross nozzles are best suited for complex geometries and intricate designs.

Y-Shaped Nozzles

Splitting the flow of molten metal into two distinct directions, Y-shaped nozzles are tailored for such functions.

Such configuration is especially beneficial while filling diverse cavities of complex molds that have more than one gate.

Increased uniform effectiveness along with reduction of uneven filling and improvement of quality casting is all achieved with dividing the flow using Y-shaped nozzles.

Best suited for achieving precision control over pump flow dynamics, this nozzle type proves deed sought after for optimal results.

Pinch Nozzles

The “pinching” motion in a nozzle creates a structure that controls the flow of molten metal. This design concept greatly minimizes splashing and enhances filling accuracy.

Pinch nozzles facilitate smooth and controlled injection of molten metal into the mold cavity. Minimizing defects and ensuring a better quality product.

Smoother splash reduction further improves the safety and precision of the die casting process. Making pinch nozzles indispensable for all die casting processes with high precision requirements.

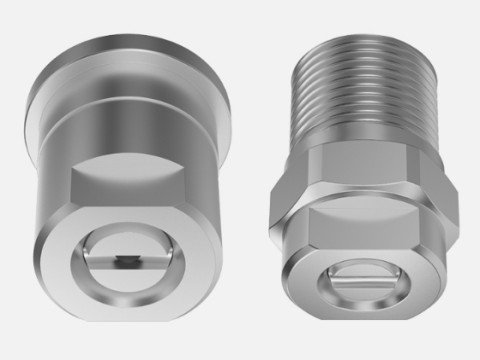

High-Pressure Nozzles

These nozzles are built for the die casting system’s stringent pressure requirements. While still providing dependable spline flow for molten metal.

Durable materials are used to construct these nozzles which will withstand the harsher conditions of high-pressure injection without losing performance during prolonged use.

Such robust design reduces wear and tear, which is important for casting precision and quality.

To achieve fast and even filling of the mold cavity, high high-pressure nozzles are required. As they enable the production of quality castings with few defects.

HAICHEN’s Advanced Die Casting Spray Nozzles

We manufacture high-performance CNC die casting machines, which we control on-site at HAICHEN, a premier manufacturer. HAICHEN focuses on producing sophisticated spray nozzles that improve the efficiency and accuracy of the die casting process.

Our product line contains T-Shaped Nozzles, Cross Nozzles, as well as Pinch Nozzles to fit different techniques and applications.

Also, these nozzles are designed for maximum coverage and cooling effectiveness, thus achieving quality castings.

HAICHEN’s enduring commitment on innovation guarantees that our spray nozzles are built with modern technology for contemporary die casting processes.

In summary, the types of die casting spray nozzles selection will improve die casting productivity. Lower operation defects, and elevate the end product quality.