Die casting spray nozzles cleaning is an important step in the die casting process. The following steps are for cleaning die casting nozzles.

Die casting spray nozzles cleaning steps

With effective steps, you can efficiently clean die-cast nozzles to extend their life and ensure they work properly.

Removing the nozzle

- First, remove the nozzle according to the unit’s instructions. We must remove and clean the screen or sieve of the nozzle separately.

Soak cleaning

- Soak the disassembled nozzle in warm water with an appropriate amount of mild detergent for a recommended soaking time of 15 minutes.

- For nozzles made of certain special materials, such as tungsten carbide nozzles, it is not recommended to use acidic solutions or strong detergents to avoid corrosion of the bonded metal.

Brushing

- Use a soft-bristled brush (such as a toothbrush) or a special nozzle cleaning brush to gently brush the residue inside and outside the nozzle.

- Be careful not to use hard brushes or sharp objects that could damage the nozzle.

Rinse

- Thoroughly rinse the nozzle with clean water to ensure that all detergent and residue is removed.

Drying

- Dry the cleaned nozzle with a clean soft cloth or blow it dry with compressed air.

- Be careful not to use compressed air to blow dry the precision part of the nozzle directly to avoid damage.

Reassembly

- We will check each part to ensure it is clean and free of residue, and then reassemble the nozzle according to its original design.

Regular Maintenance

- In order to maintain optimum performance of the nozzle, it is recommended that it be cleaned and inspected at regular intervals.

- Especially for nozzles that have not been used for a long period of time, it is recommended to disassemble them and then soak or use ultrasonic cleaning.

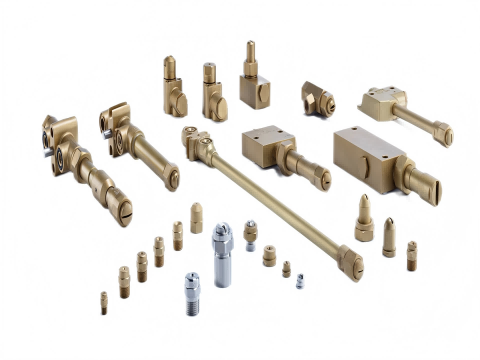

Haichen Die casting spray nozzles

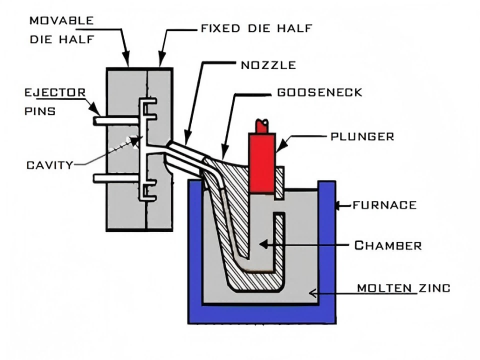

Haichen is a die casting machine factory located in Ningbo, China, mainly supplying cold chamber die casting machine and hot chamber die casting machine. Besides machines, we also supply die casting auxiliary equipments and spear parts.

The advantage of Haichen Die casting spray nozzles

Durability and long life: Haichen’s nozzles and gooseneck sections are manufactured from high-temperature and hot-worked steel, ensuring durability and long life under high-intensity working conditions.

Efficient and stable injection performance: The nozzles can effectively control the flow of molten metal into the mold in a smooth and directional manner, thus improving productivity and product quality.

Adaptable: Haichen’s nozzles are suitable for a wide range of die casting alloys, including zinc and aluminum alloys, and are able to meet the needs of different industrial applications.

Improved productivity: The efficient design of the nozzles reduces waiting time and improves overall productivity.

Properly performed spray nozzle cleaning can increase die casting efficiency and improve product quality.