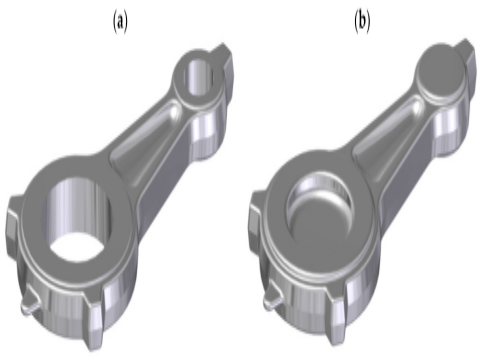

Connecting rod material of die casting include steel, aluminum alloys, titanium alloys, forged components, and sometimes composite materials.

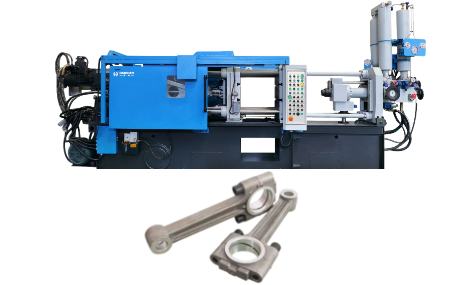

Connecting rods are essential to die casting machines, acting as the link that transfers force and movement through the system.

By translating the rotary motion generated by the drive system into the precise linear motion needed to inject metal. These rods keep the entire cycle running smoothly.

To do their job effectively, the components must endure the synergistic strain of high hydraulic pressure, cyclical bending. And abrasive contact that are hallmarks of production.

Given that these stresses accumulate with every cycle, the choice of core material is decisive in securing the rods’ longevity, operational reliability, and the overall efficiency of the equipment.

In what follows, we will detail the material options we specify for die casting machine connecting rods and clarify the performance criteria that guide those preferences.

Core Functions and Harsh Operating Conditions of Die-Casting Machine Connecting Rods

Die-casting machine connecting rods (Tie Bars) are the core load-bearing components that maintain mold closure and must meet the following requirements:

- High-strength pressure-bearing capabilities: They must withstand the immense pressure (up to 1,000 tons) of molten metal injected to prevent die flash.

- Dynamic stability: They must withstand alternating stresses and impact loads, ensuring die concentricity (accuracy ≤ 0.02 mm/m).

- Corrosion and wear resistance: They must withstand long-term contact with coolant and high-temperature metal vapor, resisting rust and wear.

Connecting rod material

The choice of material for the connecting rod is key to ensuring the lifetime, toughness, and performance consistency of a die-casting machine.

- Steel

- Aluminum Alloys

- Titanium Alloys

- Forged Components

- Composite Materials

Steel

Steel is the material of choice when manufacturing die-casting machine connecting rods, owing to the combination of high tensile strength and tough toughness with resistance to progressive fatigue. To optimize their material performance, we routinely apply heat treatments to the rods, which precisely fine-tune microstructures for greater strength, resistance to abrasion, and longevity of cyclic loading.

Aluminum Alloys

In applications with stringent weight constraints, we consider high-strength aluminum alloys. While the yield strength of these alloys is generally lower than that of heat-treated steel, the favorable power-to-weight ratio allows effective design of slender, lighter rods. On occasion, additional ribs or metal inserts are added to counterbalance the propensity for fatigue.

Titanium Alloys

In high-performance environments, grade titanium alloys satisfy requirements for lightweight, exceptional fatigue resistance, and resistance to aggressive atmospheres. Rods of this composition endure maximum loading with minimum deformation and maintain structural integrity under elevated thermal gradients. The elevated cost of titanium, however, justifies its use for premium lines with stringent tough performance guidelines.

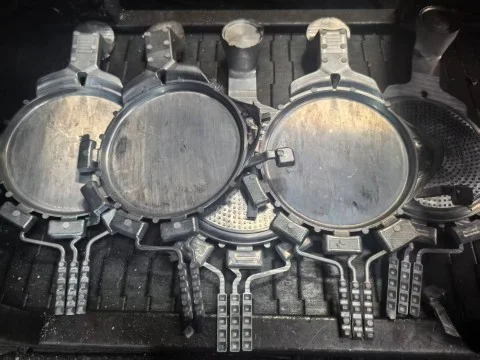

Forged Components

Forging is implemented on rods specified for high static and dynamic pressing. The resulting microstructure contains aligned crystalline phases that suppress ductile yielding even under repetitive loading. Finished rods are routinely subjected to finishing processes that remove surface porosities, and dimensional tolerances are locked with final stress-relief processes, ensuring compliant performance through the lifecycle of the die-casting machine. Forging involves shaping the material using heavy pressure, which results in a more compact grain structure and improved mechanical properties.

Composite Materials

While less common, composite materials are being explored for use in connecting rods.

We can use these materials to offer unique combinations of strength, weight, and corrosion resistance.

But we still limit their use due to high costs and complex manufacturing processes.

Core Material Selection Criteria and Industry Standards

Mechanical Property Thresholds

- Tensile strength ≥ 700 MPa (forged steel) or ≥ 690 MPa (ductile iron).

- Hardness Range: HB210-280 (cast iron) or HB229-289 (alloy steel), with hardness difference ≤ 25 HBS between components.

Process Compliance

- Metallographic Structure: Grade 1-4 tempered bainite, cracks and pores prohibited.

- Surface Treatment: Mandatory shot peening/nitriding to improve fatigue strength.

Safety Standards

- Complies with GB/T 3077 (alloy steel) or JB/T 11795 (powder metallurgy) material specifications.

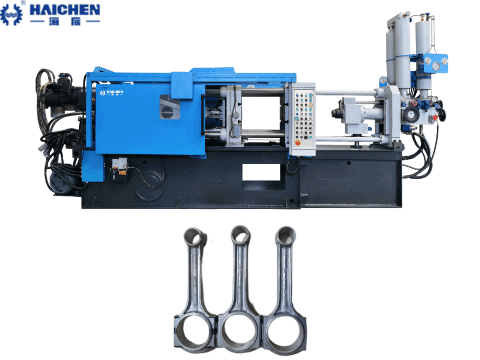

HAICHEN’s Connecting Rod Material Practice: Engineering Validation for Long-Term Reliability

HAICHEN selects connecting rod materials based on the critical balance between high fatigue strength and toughness. For our large die casting machines (e.g., over 1000T), connecting rods typically use high-strength alloy steel like 42CrMo, undergoing specific quenching and tempering heat treatment along with surface strengthening processes (like induction hardening).

This material and process combination is designed to withstand extreme alternating impact loads occurring several times per minute. In practice, for instance, on a HAICHEN 880T machine a customer uses for continuous production of auto structural parts, the connecting rods maintained their core mechanical properties and dimensional stability within design specifications even after over 2 million cycles.

This validates the crucial role of our material selection strategy in ensuring long-term, uninterrupted operation and reducing unplanned downtime.

HAICHEN: Die Casting Machine Manufacturer

HAICHEN’s die casting machines are designed to meet the highest industry standards, ensuring reliable performance and durability. Features of our machines include:

- High-quality materials: HAICHEN uses the finest materials for all components, including connecting rods, to ensure the durability and efficiency of its machines.

- Advanced Technology: Using the latest technology in the design and manufacturing process, HAICHEN’s machines are at the forefront of die casting technology.

- Customization Options: HAICHEN designs and offers a variety of die casting machines, customizing each to fit the unique requirements of various applications.

- Reliable Support: HAICHEN provides comprehensive after-sales service support to ensure that its machines operate at peak efficiency.

We choose materials for connecting rods based on factors like the type of metal we’re casting, the size of the parts, the production volume, and the specific requirements of the die casting process.