Die casting machine connectors types includes injection connection mechanism, die-cast coupling, process mold connector and so on.

In this article, we will analyse die casting machine connectors types from five points. Such as injection connection mechanism, die-cast coupling, processing mold connector, bending stamping die for converter connectors, die-casting mold for connectors.

The connector types of die casting machines can be classified and described from many aspects. The following are several common connector types:

- Injection connection mechanism

- Die casting machine connectors types: die-cast coupling

- Processing mold connector

- Bending stamping die for converter connectors

- Die-casting mold for connectors

Injection connection mechanism

- C-Frame Connection Structure

- Gooseneck Connection

- External Injection Cylinder Connection

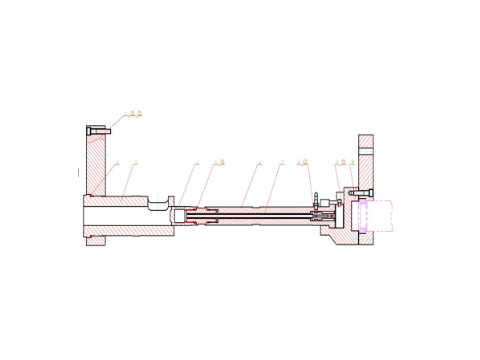

This connection mechanism mainly uses in the injection process of the die casting machine.

It includes a static mold plate and an injection cylinder. It fixes on a C-shaped frame. The open end of the C-shaped frame directly connects to the static mold plate. So to enhance the connection rigidity. This design can replace the traditional tie rod and gantry structure to improve injection accuracy and connection rigidity.

C-Frame Connection Structure

It used to enhance rigidity and injection precision. It replaces traditional tie rod and gantry structures.

Features: The open end of the C-frame (made of ductile iron) connects directly to the static (fixed) platen, simplifying the structure and improving stability.

Gooseneck Connection

Specially designed for hot chamber die casting machines.The injection mechanism is immersed in the molten metal bath, and the metal is fed into the die via a gooseneck.

Applicable Applications: Low-melting-point metals (such as zinc and magnesium) achieve rapid injection.

External Injection Cylinder Connection (Cold Chamber Die Casting Machines)

The injection mechanism is independent of the molten metal bath, and metal is fed into the injection system by scooping or automatic feeding.

Advantages: Prevents high-temperature metal corrosion from the machine and is suitable for high-melting-point metals (such as aluminum alloys).

Die casting machine connectors types: die-cast coupling

- Flexible Couplings

- Clamping Couplings

- Keyway Couplings

- Keyless Press-Fit Couplings

Die-cast coupling usually uses in inter-lockable connection assemblies.

It consists of a die-cast pocket plate or coupling with a machined surface layer. It integrally forms during the die-casting process. The pocket plate or coupling contains a pocket to accommodate and secure the locking element in the transition state of the assembly.

Flexible Couplings

These absorb vibration and misalignment (such as axial or angular misalignment). They use four retaining nuts (mounted at 90° or 120° angles). They are compact and easy to install, but may loosen over time. They are made of die-cast aluminum alloy (such as the SCT-C series).

Clamping Couplings

These feature a grooved design and are secured with hexagon socket head cap screws, providing a springy effect, easy disassembly, and minimal shaft damage.

Keyway Couplings

These feature a machined keyway to prevent slippage under high torque and are suitable for the high-load conditions of die-casting machines.

Keyless Press-Fit Couplings

These use a press-fit ring for a tight connection and are suitable for precision applications.

Processing mold connector

- Design of Mold Connection Components

- Mold Type and Connection Requirements

Processing mold connector uses in the processing mold of the connector.

It includes an upper mold base, a lower mold base, a female mold plate, a stretching male mold and a pressure plate. The female mold plate fixes to the lower mold base and has an intermediate cavity. The stretching male mold fixes to the upper mold base and can extend into the cavity of the female mold plate.

Design of Mold Connection Components

- Die-casting molds typically consist of two removable parts (a fixed mold and an ejector mold), assembled using threaded fasteners (such as bolts and dowel pins) for easy maintenance and replacement.

- The connection structure must ensure sealing under high-pressure conditions. For example, the mold’s pressure zone must precisely define the molten metal flow path to prevent leakage.

Mold Type and Connection Requirements

Single-cavity molds: Suitable for producing small or complex parts, with relatively simple connection structures.

Multi-cavity molds: Require a multi-channel connection system to ensure simultaneous filling of each cavity with molten metal, and connectors with high-precision positioning capabilities.

Bending stamping die for converter connectors

- Precision and Lifespan

- Springback Control Technology

This connector uses in the bending stamping die for converter connectors. To prevent the lower die bending punch from interfering with the material strip during feeding.

Precision and Lifespan

- The connector housing stamping die achieves an accuracy of ±0.005 inches (±0.127mm) and a die lifespan of ≥200 million cycles.

- The terminal progressive die achieves nearly 100% material utilization (zero-loss design) and a punching speed of ≥600 cycles/minute.

Springback Control Technology

For L-shaped panel bending, a single-step full bending compression method is recommended to minimize springback.

Compensation methods include adjusting the blank holder force, friction coefficient, die radius, or directly modifying the die surface.

Die-casting mold for connectors

- Cold Chamber Die Casting Mold

- Hot Chamber Die Casting Molds

It is designed based on its structural and process characteristics. And a delayed core pulling mechanism applies to realize the core pulling of the side core.

Cold Chamber Die Casting Mold

Specially designed for connectors made from high-melting-point alloys such as aluminum and copper (e.g., industrial servo motor housings). The metal is melted externally and then poured into the mold.

Features: High-temperature resistant design, suitable for the production of high-strength aluminum alloy connectors from manufacturers such as ALUNEX.

Haichen cold chamber die casting molds

Haichen produce cast aluminium cold chamber die casting molds. The die-casting mould components mainly include: a fixed mold and a moving mold, a cavity, core, inserts, and a gating system. It also with an overflow and venting system. For some complex strucutre Like alulminum alloys cookware handle with chamfer.

Haichen design it a with slider die casting mould. It need has an ejection system, including ejector pins, return pins, ejector plates, and ejector plate guide pillars/sleeves. It used to eject the solidified casting from the mold after mold closing. Haichen cold chamber cast aluminum alloys molds have relatively low strength, but have good fluidity and are suitable for casting processes.

Hot Chamber Die Casting Molds

Directly connected to a furnace, suitable for low-melting-point alloys such as zinc and magnesium (e.g., zinc alloy zipper buckles or electronic connectors).

Typical products: Zinc alloy jewelry connectors or lead terminal molds.

Haichen hot chamber die casting molds

Haichen produce hot chabmer die casting machine cast zinc alloys molds. The die-casting molds components mainly include: a fixed mold and a moving mold, a cavity, core, inserts, and a gating system. It also with an overflow and venting system. It can produce complex structure hot chabmer die casting moulds with like zinc alloy, lead alloy die casting molds. These cast zinc molds with durable and competitive price.

Therefore, these connectors types demonstrate the diverse designs and functions of die casting machines in different application scenarios. From injection connections to processing molds to dedicated connectors for specific components. Each type has its own unique structural and functional characteristics.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts. When you need any professional recommendations, feel free to contact us.