Hot Die Casting Process is a metal casting method for creating intricate parts using low melting point metals such as zinc and magnesium.

Hot die casting is a unique manufacturing procedure designed to create high-quality metal parts with precision and efficiency.

This procedure is especially beneficial for manufacturing intricate parts with small tolerances and polished surfaces.

It is especially favorable for metals like zinc, magnesium, and copper alloys which have lower melting points.

In this article, we will look at some of the most important steps in the hot die casting process and how it helps achieve quality metal parts.

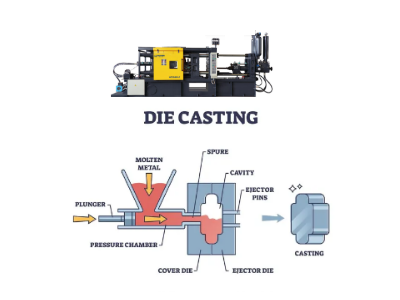

The Hot Die Casting Process

The hot die casting process starts with preparing a certain metal alloy. The alloy needs to be at melting temperature in order to be inject into a hot cavity mold.

The mold is often made of steel or other sturdy materials that can handle the hot temperatures and high pressure of the process.

And then after the high temperature metal is inject into the mold cavity, it cools and solidifies rapidly which results in acquiring the desired shape. After the part is cooled, the mold is open and the newly shaped part is remove.

- Preparation of the Die

- Material Preparation

- Injection of Molten Metal

- Solidification

- Ejection of the Casting

- Post-processing

Preparation of the Die

Die Preparation process begins with preparing the die, which consists of two parts crafted from high-quality steel. The die contains cavities that correspond to the shape of the final product.

And then to ensure uniform and quick solidification of the molten metal, the die is preheate to a specific temperature and held there.

Material Preparation

Material selection is equally important for hot die casting. Zinc, magnesium, and aluminum alloys are frequently use, each possessing distinct advantages for specific use cases.

For instance, zinc alloys are often utilized in precision small parts due to their exceptional surface finish. Magnesium alloys are lightweight yet strong, thus used for aerospace and automotive parts.

Aluminum alloys are use widely as they provide strength and durability along with corrosion resistance.

Injection of Molten Metal

The die is then filled with molten metal that is preheate to a specific temperature and held there.

The molten metal is then injected to the die under high pressure which ensures all details of the die cavity are filled, resulting in a part that is both precise and detailed.

Haichen’s advanced injection systems ensure precise control over the injection process, resulting in high-quality castings with minimal defects.

Solidification

After the metal is inject, it quickly solidifies inside the die. The solidification process is uniform and minimal defects like porosity or shrinkage are achieved due to high pressure and preheated die.

Ejection of the Casting

Once the metal solidifies, the die halves gets separate, and the casting is remove using an ejector pin. the casting undergoes additional processes such as trimming or finishing to remove excess material.

Post-processing

the casting is subjected to machining and heat treatment and other operations to improve the mechanical properties and cosmetic features.

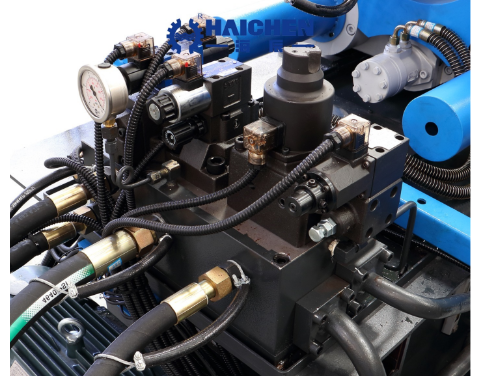

Key Components of Hot Chamber Die Casting Machines

Hot chamber die casting machines consist of several key components, including:

- Furnace: Maintains the metal in a molten state.

- Gooseneck: Transfers molten metal to the injection chamber.

- Nozzle: Connects the injection chamber to the die.

- Plunger: Injects molten metal into the die.

- Hydraulic System: Powers the injection process.

Furnace

The furnace maintains the metal in a molten state, providing a stable heat source to keep the alloy at the required temperature for injection. It is typically integrated with the machine’s base and features advanced temperature controls to ensure consistent heat.

Gooseneck

The gooseneck transfers molten metal from the furnace to the injection chamber, ensuring smooth and efficient metal flow. It is make from high – temperature – resistant materials and may include internal heating elements to maintain metal temperature during transfer.

Nozzle

The nozzle connects the injection chamber to the die, controlling the flow of molten metal into the mold cavity. It is design for precise flow control, ensuring even and consistent metal injection to reduce defects like porosity or incomplete filling.

Plunger

The plunger injects molten metal into the die, moving under high pressure to fill the mold cavity quickly and uniformly. It is make from high – strength materials and features precise control mechanisms to optimize injection speed and pressure.

Hydraulic System

The hydraulic system powers the injection process, providing the necessary force and control for the plunger’s movement. It includes hydraulic pumps, valves, and cylinders, and often features advanced controls for precise and consistent operation.

Advantages of Hot Chamber Die Casting

Hot chamber die casting offers several advantages, including:

Less Material Waste: The continuous flow of molten metal reduces oxidation and material loss.

HAICHEN’s Core Technical Advantages in Hot Chamber Machines

HAICHEN hot chamber die casting machines are design for efficient, precision production of low-melting-point alloys like zinc and magnesium. Their core strengths lie in solving the unique challenges of hot chamber processing.

- Integrated Precision Temperature Management

- Efficient and Durable Gooseneck System

- Fast Response and Precise Injection Control

- Case in Point: Mass Production of Zinc Alloy Precision Lock Parts

Integrated Precision Temperature Management

HAICHEN machines feature an intelligent, integrated temperature control system for the furnace, gooseneck, nozzle, and mold. Using high-precision sensors and PID closed-loop control, temperature fluctuation of the alloy is minimized (typically within ±3°C) throughout its journey from the furnace to the cavity. This prevents issues from uneven temperature, like changed flow behavior or oxidation, forming the foundation for consistent, high-surface-quality castings.

Efficient and Durable Gooseneck System

Addressing the core hot chamber challenge of gooseneck corrosion and buildup from constant molten metal contact, HAICHEN uses special alloys, optimized internal channels, and can apply specialized coatings to key surfaces. This significantly improves erosion resistance and service life, reducing downtime for maintenance or part replacement.

Fast Response and Precise Injection Control

HAICHEN’s servo-driven injection system enables millisecond-level “slow-fast-slow” multi-stage shot control. A slow initial phase expels air, followed by high-speed filling of complex cavities and thin walls, ending with a precise switch to intensification pressure. This ensures perfect detail replication while drastically reducing porosity and cold shut defects.

Case in Point: Mass Production of Zinc Alloy Precision Lock Parts

A high-end lock manufacturer uses HAICHEN hot chamber machines to produce zinc alloy faceplates and complex internal components with strict cosmetic requirements. Thanks to the stable temperature and injection control, the product’s chrome-plating yield rate has remained above 99.2% over years of mass production, with mold life exceeding 800,000 shots. This fully demonstrates HAICHEN hot chamber machines’ combined advantages in precision, stability, and durability.

Haichen Hot Chamber Die Casting Machine Customer Case:

Zinc Alloy Medal Making Machine

Haichen has over 10 years experiance for medal casting, and coins casting. It produces medal making machine of zinc alloy, and challenge coins casting machine.

Under medal making process, different kind of zinc alloy medal and coins can be designed and made by Haichen medal making machine with mould. Like single, double-sided figure zinc alloy medal, or round, square, polygonal zinc alloy medal and challenge coins.

Zinc alloy round medal

- Item: zinc alloy round medal Size: 70 mm,34g

- Material: zinc alloy

- Cavities: 4 cavities

- Thickness: 1.4mm

- Machine: 90ton medal making machine

The customer can DIY different styles on the medal surface, by using paste paper or carving shapes on it. That’s a changeable option, it can help save the cost.

Automotive Parts Smart Upgrade

- Faster Cycle Times: Due to the integrated furnace, the process is quicker than cold chamber die casting.

- Lower Energy Consumption: The continuous melting process reduces energy use.

- Automated Operation: The process is highly automated, reducing labor costs and increasing consistency.

- A russian automotive parts supplier adopted the Haichen HCD-H series hot chamber die casting machine for mass production of zinc alloy injector shells with stringent air-tightness requirements of 0.05MPa.

- Core Challenges:Slow production cycles and low yields of strongly overmolded thin-walled components which was sitting around 83%.

- Haichen provided the customer with the following solutions:The customer solutions provided by Haichen include ultra-high-speed injection (compression speed of 6m/s), intelligent mold clamping (2500T constant force), and advanced temperature control systems.

- The customer’s product operation results:The customer’s product operation results are as follows: yield increased to 98.5%, cycle time reduction to 19 seconds. And then mold life increased by over 40% surpassing 500,000 die times.

Applications and Advantages of Haichen Hot Chamber Die Casting Machines in Precision Medal Manufacturing

Medals, commemorative medals, and similar products have near-stringent requirements for surface finish, clarity of pattern details, dimensional consistency, and high-efficiency mass production. Hot chamber die casting, with its fast forming speed, dimensional stability, and excellent surface quality, has become the ideal choice for manufacturing zinc alloy medals.

Process Optimization for Medal Characteristics and Haichen’s Expertise

Medals typically have complex structures, including intricate reliefs, text, edge serrations, and other details, and are often thin-walle parts (e.g., 1.4mm thick).

Haichen’s hot chamber machines undergo in-depth optimization in the following aspects to ensure perfect molding:

- Ultra-precision injection control: Haichen’s servo-driven injection system achieves millisecond-level “slow-fast-slow” multi-segment speed and pressure control. Low-speed advancement in the initial filling stage to expel gas from the cavity, followed by high-speed filling of complex patterns, and finally precise pressure increase to compensate for shrinkage. This ensures that the molten metal perfectly replicates the finest textures on the mold, avoiding flow marks, cold shuts, or incomplete filling.

- Intelligent Temperature Co-management: Medal production requires extremely stable mold temperatures. Haichen’s system implements closed-loop linkage control of the furnace, gooseneck tube, and mold temperatures. Through high-precision sensors and PID algorithms, temperature fluctuations at each point are controlle within ±2°C, providing a stable thermal balance for continuous production and ensuring that the surface gloss and dimensions of each medal are completely consistent.

Haichen Medal Manufacturing Case Study: In-depth Analysis

Taking a customer’s production of a 70mm diameter, approximately 34g zinc alloy round medal as an example, Haichen provides the following complete solution:

- Core Equipment: HAICHEN H-series 90-ton precision hot chamber die-casting machine.

- Mold Solution: 4-cavity mold, mirror-polished cavities, with detail engraving accuracy up to ±0.02mm.

- Process Flow:

- Melting and Holding: The zinc alloy is melte in an integrated furnace and maintain at an optimal temperature of 415±5°C.

- Precision Injection: Through Haichen’s patented “closed-loop feedback injection system,” the alloy is injecte into the mold with an optimized curve.

- Rapid Cooling and Ejection: The mold features a built-in high-efficiency cooling channel, allowing the medal to solidify within seconds and be smoothly ejected by precisely positioned ejector pins.

- Automated Post-Processing: It can be connected to Haichen’s automated production line for automatic gate removal, polishing, electroplating, or spraying.

- Customer Value:

- High Quality: The medal surface is flawless, with clear and three-dimensional patterns, allowing for direct post-processing electroplating or painting.

- High Efficiency: The 4-cavity mold, combined with high-speed circulation (cycle time as short as 6-7 seconds), enables a daily output of tens of thousands of medals, greatly meeting the bulk production needs of large-scale events or commemorative activities.

- High Flexibility: Customers can quickly switch between producing medals or challenge coins of different designs and shapes (round, square, irregular shapes) on the same Haichen machine by changing mold inserts, achieving “one machine, multiple designs.”

Hot die casting has a few advantages which includes high production speeds, great accuracy. And then the ability to produce thin walled intricate shapes.

In conclusion, these are use in the automotive, aerospace and consumer electronics industries. Or, it is used to make parts like engine housings and electronic casings.