Advantages of Mold Materials in die casting include high thermal conductivity, excellent mechanical properties, precision, durability,etc.

Die casting is a precision method of metal casting where molten metal is injected under pressure into a precisely made mold.

The selection of the mold material can affect the efficiency and the durability of the product.

In this article we will discuss the benefits of different die casting mould materials and how they help achieve success in the die casting process.

Selection of materials is essential for the efficiency and perfection of the dies. Here are some key advantages of Die Casting high-grade die casting mould materials.

High Thermal Conductivity

Die Casting mold materials, like certain steel alloys, exhibit very good thermal conductivity.

This is important for the heat transfer from the molten metal to the die so that the metal solidifies uniformly and rapidly.

Materials like H13 tool steel and some copper alloys are used because of their good thermal conductivity.

These materials ensure that the heat from molten metal is effectively removed so that the molten metal cools evenly, thereby improving the dimensional accuracy and reduction of the defects like porosity and shrinkage in the final castings.

High thermal conductivity also assists in preserving the surface finish of the part, which is especially important for applications requiring visual appeal alongside precision.

To achieve castings of high quality while reducing the need for extensive finishing processes, it is beneficial to use molds with high thermal efficiency.

Excellent Mechanical Properties

High-quality mold materials have remarkable mechanical properties that include strength, toughness, and both wear as well as thermal fatigue resistance.

These characteristics allow the mold to endure the intense pressures and high temperatures of the die casting process without yielding, resulting in increased durability and production consistency for high-quality castings.

Precision and Durability

The materials used for die casting molds undergo precision machining and are design for retention of dimensional stability over time.

Such durability is essential in the production of complex and intricate components which require tight tolerances. Retention of precision means each casting can be produced to the required specifications, thereby reducing secondary machining steps needed and improving production efficiency.

Versatility

High-quality mold materials are applicable to a broad range of metals and alloys. Such as aluminum, zinc, magnesium, and copper alloys.

This flexibility allows manufacturers to utilize a single mold material to produce a wide variety of parts. This makes the die casting process more cost-effective and adaptable to different production needs.

Zinc alloys are suited for complex components like connectors. And fittings whereas aluminum alloys have applications in the automotive and aerospace industries owing to their light weight and strength. For devices and power tools, magnesium alloys are critical where weight reduction is vital. Copper alloys are use in electrical as well as plumbing components due to their outstanding thermal and electrical conductivity.

Using high-grade tool steels and stainless steels like H13 which can withstand extreme temperatures and corrosive environments enables manufacturers to improve flexibility and efficiency in operations by reducing the number of molds needed. Streamlined production is achieved with reduction in processing steps.

Easier Maintenance

Less frequent maintenance is essential, especially for materials that are resistant to wear and corrosion.

These wear resistant materials improve maintenance costs and downtime.

The exposure stainless dies face to molten metal and extreme temperatures enables the dies to endure repeated die casting cycles.

With increased uptime and refined production schedules, productivity rises.

The precision offered by these materials over time enhances the consistency in quality of the castings made.

By choosing mold materials with excellent resistance to wear and corrosion, manufacturers can achieve more reliable and cost-effective production processes.

Detailed Explanation of Key Die Casting Mold Materials

Choosing the right mold material is crucial for the lifespan of die casting molds and the quality of the final die castings. Below are some commonly used and critical die casting mold materials and their characteristics:

- H13 Hot Work Mold Steel

- High Hardness Mold Materials

- Corrosion-Resistant Mold Materials

- Other Specialty Materials

H13 Hot Work Mold Steel

This is one of the most commonly used die casting mold materials, especially suitable for aluminum alloy and magnesium alloy die casting.

H13 steel exhibits good hot work strength, wear resistance, and thermal fatigue resistance at high temperatures, capable of withstanding repeated impacts and thermal cycles from molten metal.

Its overall mechanical properties and thermal conductivity are well-balanced.

High Hardness Mold Materials

Materials such as 2344 (corresponding to the Chinese grade 4Cr5MoSiV1) and 8407 are typically used in the production of hard molds requiring a longer lifespan.

These materials can achieve a service life of over one million cycles. Although more expensive, they are suitable for products with very high production volumes.

Corrosion-Resistant Mold Materials

For molds molding highly acidic plastics such as PVC, materials like 2316. Which offer high surface finish and high acid resistance, are used.

Although rarely used directly in die casting, this material selection approach—choosing materials based on their properties—is worth considering.

Other Specialty Materials

In specific parts of the mold, such as the core or slide, materials like powder high-speed steel or cemented carbide (such as V40) may be used.

These materials possess extremely high hardness (e.g., 87-88 HRA or higher) and wear resistance. Designed to withstand special wear, high temperatures, or corrosion resistance requirements.

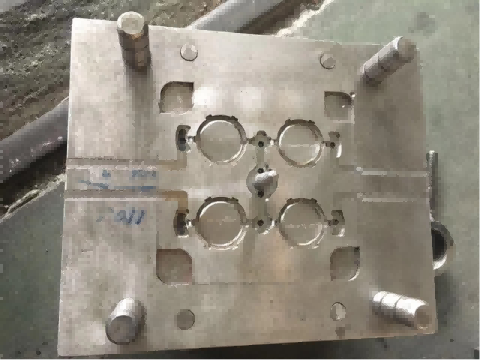

Machining mold materials requires equipment such as CNC precision machining centers, wire EDM machines, and grinding machines, with precision requirements typically controlled within ±0.005 mm. With industrial development, mold core material systems have expanded from basic steel grades to acid-resistant, high-wear-resistant special alloys.

Haichen’s Commitment to High-Quality Die Casting Mould Materials

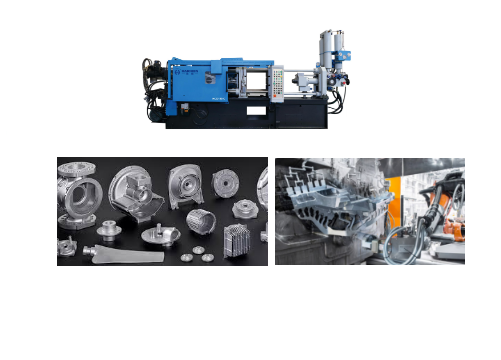

At Haichen, we know that die casting mould materials are crucial in the manufacturing process to achieve high-quality, long-lasting castings.

We have invested in die casting machines that are compatible with diverse mould materials to maximize their productivity and efficiency.

We focus on H13 tool steel and similar materials for high precision and high wear applications. As they have exceptional wear resistance and thermal stability.

Our advanced control systems allow these materials to be utilized optimally which, in turn. Improves the precision and consistency of the castings produced.

Our customers receive our advanced machines together with high-quality mould materials to achieve production and quality targets in a cost-effective manner.

Haichen’s Innovation in Mold Technology

Continuously invests in mold design and manufacturing technologies.

For example, we focus on advanced machining technologies in mold manufacturing. In mold cavity manufacturing, high-speed machining (HSC) technology, compared with traditional electrical discharge machining (EDM), offers advantages such as lower energy consumption and higher processing efficiency in certain situations, which helps improve mold quality and manufacturing efficiency.

Emphasizes practicality and innovation in mold structure design.

For example, one of our solutions involves a mold structure that facilitates demolding, with its core assembly including an ejectable die core and a specially designed slide mechanism, which facilitates smooth demolding and improves operational stability. This demonstrates Haichen’s commitment to optimizing the entire process from mold materials and design to manufacturing, providing customers with more reliable die-casting solutions.

Integrated solutions for optimal performance

Haichen’s unique advantage lies in optimizing mold materials, mold design and die-casting host as an overall system.

Synergy of Process Parameters and Material Properties: Our advanced control system not only controls the die-casting process but also works in conjunction with the mold’s temperature control system. For example, before production begins, the system automatically calculates and executes the optimal preheating procedure based on the specific heat capacity of the mold material (such as the high thermal conductivity copper alloy insert area) to avoid thermal shock. During production, the system monitors the temperature of key mold points in real time and dynamically adjusts the cooling water flow to ensure thermal balance, thereby fully utilizing the material’s thermal conductivity and fatigue resistance properties.

Innovative Mold Structure Design: Haichen is committed to designing mold structures that facilitate demolding and enhance stability. For example, one of our patented designs includes a pop-out core and a specially designed slider mechanism. This structural optimization not only improves operational stability, ensuring smooth demolding of complex parts (such as automotive parts with internal threads or deep ribs), but also reduces abnormal mechanical stress on the mold material, protecting expensive mold materials and extending their service life.

The die casting process benefits from the advantages that die casting mold materials have to offer.

These properties, together with ease of maintenance, high thermal conductivity. Superb mechanical characteristics, versatility, precision. And enduring strength enable manufacturers to produce castings that are complex in geometry and tight in tolerances.

Advantages of Mold Materials, the development of even more sophisticated mould materials will further enhance the capabilities of die casting. Allowing for greater innovation and efficiency in the production of metal components.