Selecting the right die casting mould material involves considering factors such as the type of metal being cast, the complexity of the part, production volume, and the desired lifespan of the mold.

The selection of the right material for a die – casting mold is crucial for ensuring the efficiency, quality, and longevity of the die – casting process.

This choice directly impacts the precision, durability, and cost – effectiveness of the production. Understanding the specific requirements of your die – casting application and the properties of available mold materials is essential for making an informed decision.

This article will provide detailed guidance on how to select the right material for your die – casting mold, ensuring high – quality parts and efficient production.

By considering factors such as the type of metal being cast, the complexity of the part, production volume, and desired mold lifespan. Manufacturers can optimize their mold selection and enhance overall production outcomes.

Common die casting mould material

Die casting molds are usually made of high-quality alloy steel with good hardness, toughness, and wear resistance. The most commonly used materials for die casting molds include:

- H13 Tool Steel

- NAK80 Tool Steel

- 8407 Tool Steel

- Aluminum

H13 Tool Steel:

This is the most commonly used material for die casting molds because it combines hardness, toughness, and resistance to thermal fatigue.

NAK80 Tool Steel:

NAK80 is a pre-hardened steel with excellent dimensional stability and wear resistance, making it an ideal material for producing high-precision parts.

8407 Tool Steel:

This material is highly resistant to heat, abrasion, and corrosion, and is commonly used in high-pressure die casting applications.

Aluminum:

Some low-volume or prototype die casting molds may be made of aluminum to reduce costs and lead times. However, aluminum molds have a shorter lifespan than steel molds.

How to Select Right Material of Die Casting Mould

When selecting die casting mold materials for industrial applications. It is important to consider the application and select the material that best suits your needs.

Here are some tips for choosing the right die casting mold material:

- Basic requirements for materials

- Production volume and cost

- Metal type of die casting mould material selection

- Expected service life

Basic requirements for materials

The mold material must have high thermal resistance, excellent thermal conductivity. And good dimensional stability to meet the challenges of high temperatures. And repeated heating and cooling during the die casting process.

The material should have sufficient strength, toughness, and wear resistance to withstand the impact and abrasion of the liquid metal.

Production volume and cost:

For large-scale production, it may be more economical to choose a lower-cost material with high durability (e.g., H13 tool steel).

Metal type of die casting mould material selection:

Different metals have different melting points, fluidity and shrinkage rates. So it is necessary to select the appropriate mold material according to the characteristics of the metal being cast.

Expected service life:

If the mold needs a longer service life, you can choose a high-strength material with special heat treatment. Such as H13 or SKD61.

HAICHEN Material Selection Support

Mold material selection must align with production conditions. HAICHEN provides synergistic selection support based on its equipment and customer experience.

- Selection Advice Based on Machine Performance

- Failure Analysis and Material Upgrade Case

- Database Support for Selection

Selection Advice Based on Machine Performance

HAICHEN engineers provide targeted mold material advice based on their machines’ clamping force and injection performance. For example, when using HAICHEN large-tonnage machines for high-vacuum casting, premium H13 or high-end materials with better thermal crack resistance are recommend to meet the higher process demands.

Failure Analysis and Material Upgrade Case

In one case, a customer’s core insert cracked after 80,000 cycles. HAICHEN analysis led to upgrading the material to ESR H13 steel with optimized heat treatment. This extended the mold life to over 150,000 cycles, proving the long-term value of better materials.

Database Support for Selection

HAICHEN’s database links material properties with production process data from its machines. Customers can use it to get matche “material-process” combinations quickly, reducing trial and error costs.

HAICHEN Mold Material Selection Case: 280mm Aluminum Fry Pan Mold

HAICHEN selects mold materials based on part features, production needs, and cost. For the 280mm aluminum fry pan mold, the part had thin walls and a deep cavity. It needed to withstand frequent high-temperature aluminum (about 660°C) impact and thermal stress. The customer required high output (over 300,000 shots) and excellent surface finish.

- Challenge: Standard mold steel could develop heat-check cracks under long-term thermal cycling, affecting the pan’s surface and dimensional stability.

- HAICHEN Solution: We recommended premium H13 hot-work tool steel (like DIN 1.2344/ESR) with strict vacuum hardening and double tempering. This ensured uniform hardness (HRC 48-50) and superior thermal fatigue resistance. Critical areas like the deep cavity and gate received local nitriding for extra wear resistance.

- Result: The mold achieved stable mass production on the customer’s HAICHEN 650-ton machine with a 45-second cycle. After over 300,000 shots, the main mold body showed no visible heat checks, and key dimensions stayed stable. The part surface quality consistently met requirements, far exceeding the customer’s initial expectations. This proves the long-term value of coordinated material and process selection.

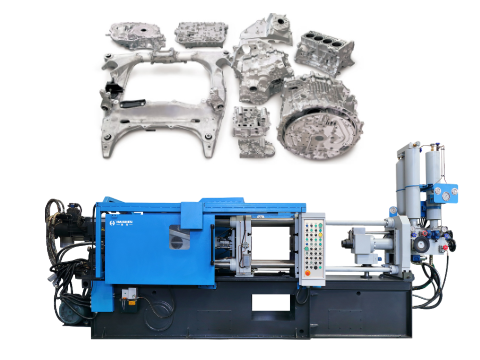

Haichen die casting mould supplier

Haichen is a die casting mould supplier and we have more than 20 years of experience in the production of die-casting mould, cold chamber and hot chamber die casting machines.

Our die-casting molds are widely use in the manufacture of automotive parts, including components for traditional and new energy vehicles. And are also use in the manufacture of aluminum housings, lock cylinders, door handles, etc.

If you are interest in Haichen’s die-casting molds or relate products, please feel free to contact us.

Choosing the right material for die casting molds requires comprehensive consideration of production requirements, expect service life, cost. And the characteristics of the metal being cast.

Through the reasonable choice of materials, can significantly improve the quality and service life of the mold, so as to ensure the stability and consistency of die casting products.