Die casting mould materials:

- Steel

- Carbon steel

- Alloy steels

- Stainless steel

- Cemented carbide

- Non-metallic materials

- Tool steels

- Copper alloys

These materials need to be high-strength, abrasion-resistant, and heat-resistant to withstand the high temperatures and pressures generated during the die casting process.

Die casting molds, also known as dies, are typically made from high-grade tool steels, such as H13 steel, which are known for their durability, heat resistance, and toughness.

These steels are specifically chosen to withstand the extreme pressures and high temperatures involved in the die casting process.

Other materials like high-speed steel or high-alloy steel may be used for specific applications.

What is die casting mould material?

Die casting mould material is a type of metal alloy used to form parts and components for industrial applications.

The material is heated to a molten state and then poured into a mould, where it cools and hardens into the desired object.

This process allows for precise shapes and dimensions, as well as strength and durability.

Die casting mould material is often used in the automotive, aerospace, and medical industries.

As it can provide superior strength and performance compared to other materials.

It can also be used in the production of items such as coins, medals, and other small items.

Die casting mould material–Steel

Steel is one of the most commonly used materials in die casting molds.

With high strength, good toughness, and wear resistance.

Die casting mould material–Carbon steel

Carbon steel is an alloy composed mainly of iron (Fe) and carbon (C), with a carbon content usually ranging from 0.0218% to 2.11%.

Such as Q235, Q345, etc., with good processing performance and low production cost.

Die casting mould material–Alloy steels

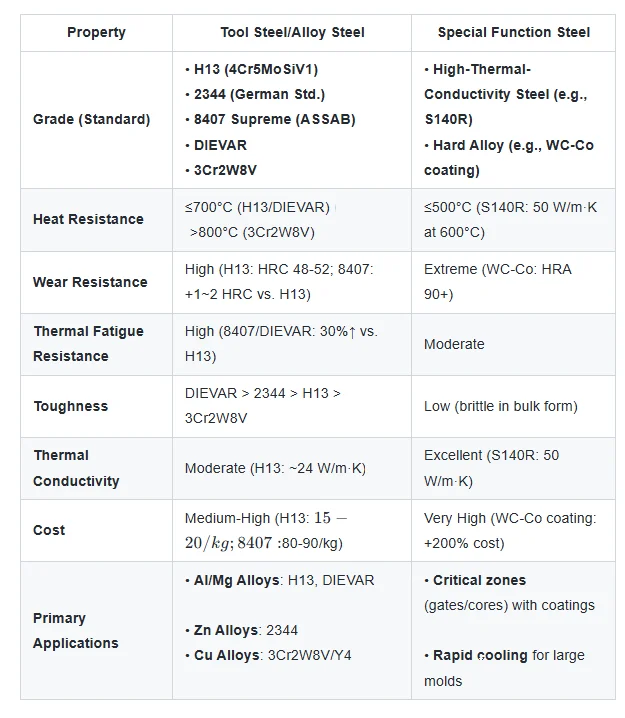

Such as H13, SKD61, DAC, 2344, 8407, etc., these steels have higher hardness and wear resistance after heat treatment, which are suitable for manufacturing large and precision molds.

Die casting mould material–Stainless steel

Such as 304, 316, etc., with excellent corrosion resistance and oxidation resistance, suitable for use in wet or corrosive environments.

Aluminum alloys

Aluminum alloys are widely used in die casting molds because of their low density.

Good thermal conductivity, and corrosion resistance.

Commonly used aluminum alloy materials include: AlSi10Mg, AlSi9Mg, etc.

Which are suitable for manufacturing mold shells and internal cooling elements.

H313, SKD61, DAC, 2344, 8407 and other aluminum alloy mold steels, with good wear resistance and corrosion resistance, are suitable for the manufacture of mold cavities and cores.

Die casting mould material–Cemented carbide

Tungsten carbide such as tungsten carbide (WC), titanium carbide (TiC-Ni), etc.

Are often used for the surface coating of mold cavities and cores.

Because of their high hardness and wear resistance to improve the service life of molds.

High wear resistance type :

CY288 (ultra-fine grain): high edge strength, suitable for precision blanking.

High toughness type :

Steel-bonded carbide : Improved impact resistance, can replace mold steel.

EDM-specific type :

CY466 : Medium cobalt, medium coarse grain structure, resistant to electrical machining cracking.

Die casting mould material–Non-metallic materials

Non-metallic materials such as ceramics, graphite, etc., have gradually become one of the choices for die-casting mold materials because of their light weight, high strength and corrosion resistance.

These materials are often used in certain parts of molds to improve wear resistance and extend service life.

Die casting mould material–Tool steels

Tool steels have high hardness, high strength, and wear resistance, making them suitable for molds that are produced in high volumes.

For example, tool steels such as S136, H13, etc., are often used to make durable molds.

H13 Tool Steel: This is the most commonly used material for die casting molds due to its excellent combination of hardness, toughness, and thermal fatigue resistance.

NAK80 Tool Steel: NAK80 is a pre-hardened steel that offers excellent dimensional stability and wear resistance, making it ideal for producing high-precision parts.

8407 Tool Steel: This material is highly resistant to heat, wear, and corrosion, and is often used in high-pressure die casting applications.

High-temperature performance

Tool steels have good hardness and red-hardness at high temperatures, which allows them to maintain the sharpness and wear resistance of the cutting edge in high-temperature environments.

High Speed Tool Steels (HSS) exhibit good heat and wear resistance in the temperature range of 600-1000°F (about 315-538°C).

5CrW2Si alloy tool steel exhibits excellent hardness and strength in high temperature and high pressure environments, and is not easy to deform or break.

Abrasion and impact resistance

Tool steels have excellent wear and impact resistance, making them suitable for environments that need to withstand heavy loads and complex stresses.

High-speed tool steels have high hardenability and high toughness.

And are suitable for manufacturing high-speed cutting tools such as drills, reamers, and broaches.

Applicable conditions

Tool steels are widely used in the manufacture of cutting tools, molds, measuring tools, etc., especially under high temperature conditions.

Different grades of tool steels (e.g. air hardening, water hardening, oil hardening, etc.) are suitable for different applications according to their characteristics.

Die casting mould material–Copper alloys

Copper alloys are often used to maintain the accuracy and stability of molds due to their excellent thermal conductivity, electrical conductivity, and corrosion resistance.

For example, H13 steel is a commonly used copper alloy material.

Thermal conductivity and corrosion resistance

Copper alloys have good thermal conductivity and corrosion resistance, making them suitable for specific high-temperature and high-pressure occasions.

Such as high-temperature steam pipelines and water treatment systems.

Applicable conditions

Copper alloys are commonly used in the manufacture of components such as spherical compensators.

which need to maintain stability and durability in high-temperature and high-pressure environments.

The application of die-casting mold materials

Die-casting mold materials serve widely across industrial fields, including hardware accessories, automotive, aerospace, and medical components; they also produce coins, medals, and other small items.

Moreover, these materials enable the manufacturing of complex-shaped parts, such as electronic industry die-castings.

Specifically, in the automotive sector, manufacturers apply die-casting molds to create wheels, brake systems, and exhaust components.

furthermore, the aerospace industry relies on them for engine parts, aircraft structures, and navigation systems .

Additionally, medical fields utilize die-casting molds to fabricate surgical instruments and biocompatible implants.

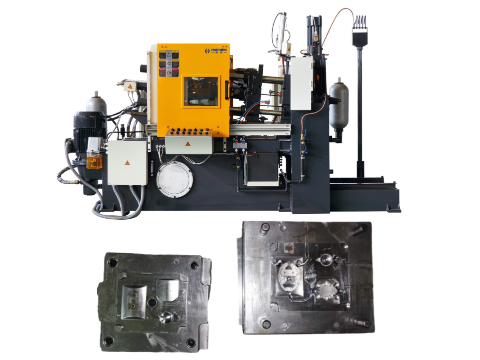

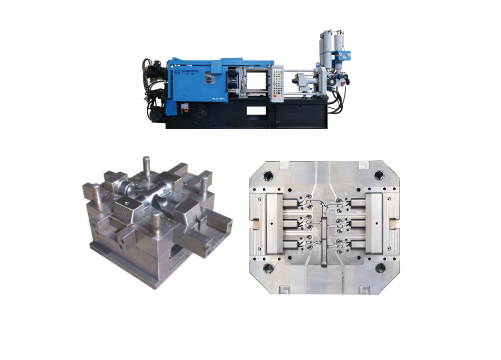

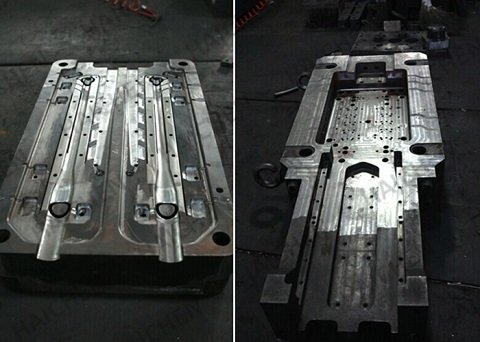

Haichen die casting mould

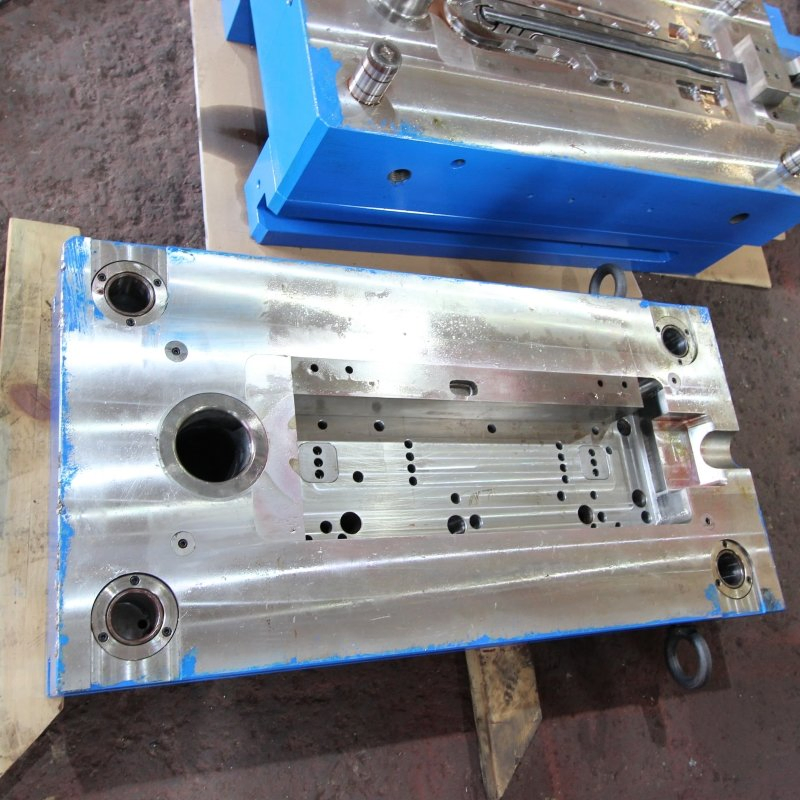

Haichen’s die casting molds are typically made of high-strength tool steel to withstand high temperatures and pressures.

In terms of design, Haichen’s molds include cavities, pouring systems, ejection mechanisms, etc. are precisely designed to ensure the quality of parts and reduce defects.

Therefore, Haichen’s die casting molds have a long life and can produce large quantities of parts.

Haichen‘s suggestion – choose the right mold material

Choosing the right mould material is essential to ensure the durability and productivity of the mold.

The choice of mold material needs to be considered based on factors such as expected production volume, part complexity, and mold life.