Types of die casting machine boosting cylinder:

- Single-rod hydraulic cylinder

- Back-pressure booster cylinder

- Pressurized Pressurized Cylinder

- Split Booster Cylinder

- Direct Pressure Booster Cylinder

- Standard booster cylinder

- Electric Booster Cylinder

- Local Booster

- Pressure Control Circuit Booster Cylinder

Boosting cylinder of die casting machine, which are very critical components in the die casting process, and their main role is to provide additional pressure in the injection stage to ensure the quality and molding accuracy of die castings.

Types of boosting cylinder–Single-rod hydraulic cylinder

This type of booster cylinder has a simple structure, but the pressurization process is relatively slow, and it is suitable for some occasions where the pressurization speed is not high.

The hydraulic oil enters the oil inlet of the hydraulic cylinder through the A and C ports, pushes the piston to stretch outward.

And drives the piston rod and the pushout mechanism to work together to complete the forming of the workpiece by the injection punch.

Types of boosting cylinder–Back-pressure booster cylinder

Increases load capacity by increasing the reverse pressure in the volumetric cavity and is suitable for cold die casting of thicker plates.

Back-pressure booster cylinders typically have a high output pressure to meet specific process needs.

Specifically, when the main cylinder (i.e., the injection cylinder) hits the head, due to the instantaneous high pressure of the hydraulic oil.

The back pressure chamber in the booster cylinder will quickly establish pressure, thereby pushing the booster piston to pressurize the operation.

This design enables the booster cylinder to reach the required boost pressure in a very short time, thus guaranteeing the molding quality of the die casting.

Types of boosting cylinder–Pressurized Pressurized Cylinder

This type of pressurized cylinder can be used as a gas-liquid pressurized cylinder and is suitable for cold die casting of sheet metal.

The pressurized booster cylinder can be designed to increase the air pressure, thereby improving the overall boosting effect.

Types of boosting cylinder–Split Booster Cylinder

A split booster cylinder is a pressurization system that is designed separately from the hydraulic cylinder and the booster.

High-precision control

More precise control can be achieved due to the separation of the hydraulic cylinder and the supercharger by the split booster cylinder.

The piston rod of the hydraulic cylinder automatically starts after contacting the working fluid.

And the action speed is fast and more stable than the pneumatic transmission.

Low energy consumption

The split booster cylinder can achieve high output of the hydraulic press under the same conditions, and the energy consumption is low.

Easy installation

The split booster cylinder can be installed at any angle of 360 degrees, with strong adaptability.

Long life

Due to the reasonable structural design, there are few failures, small temperature rise problems, and long service life.

Types of boosting cylinder–Direct Pressure Booster Cylinder

This booster cylinder directly combines the booster with the cylinder, and uses pure air pressure as the power source, which is suitable for occasions that require a quick response.

Fast and efficient

The direct pressure booster cylinder adopts the whole high-pressure stroke, and directly connects the air pressure short-stroke work at the rear end of the cylinder, which is suitable for short-stroke design work.

High output force

The output force of the direct pressure booster cylinder is large, up to 13 tons.

Mechanical designers appreciate

Despite its large size, it has a compact design.

Types of boosting cylinder–Standard booster cylinder

Also known as pre-loaded booster cylinder, it is divided into two strokes, the first push out of the cylinder and contact with the workpiece, and then the second stage of high-pressure stroke.

Standard booster cylinders are typically used in applications that require longer strokes and higher pressures.

Hydraulic Booster Cylinder

This is the most common type of pressurization, and the boost pressure is provided by a hydraulic system.

Hydraulic booster cylinders are commonly used in conventional die-casting machines, where the piston rod is pushed by the hydraulic cylinder to achieve pressurization and clamping action.

Types of boosting cylinder–Electric Booster Cylinder

With the development of technology, some new types of die-casting machines have begun to use electric booster cylinders.

This type of pressurization is more efficient and less expensive to maintain than traditional hydraulic systems, and is suitable for applications that require fast response and high-precision control.

Local Booster

Cylinders In some designs, booster cylinders are placed at specific locations in the mold to provide local boost.

This allows for better control of the pressure distribution within the mold, which improves the quality of the casting.

Pressure Control Circuit Booster Cylinder

This type of booster cylinder uses a pressure control circuit to adjust the pressure change.

During the pressurization process, so as to ensure the quality stability of casting production.

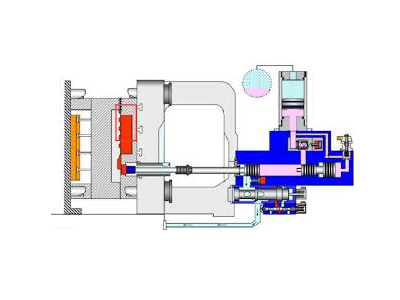

The working principle of the booster cylinder

The booster cylinder is a device that combines the hydraulic cylinder with the supercharger.

And uses the principle of Pascal energy conservation to increase the air pressure.

By changing the pressure cross-sectional area to achieve dozens of times the pressure increase.

Its working principle is based on the fact that when the pressure is constant.

The pressure changes due to the change in the compression area.

The four stages of a booster cylinder

In the oil inlet stage, the hydraulic pump supplies oil to the working chamber.

the piston moves to the right, and the pressure in the working chamber decreases.

During the working phase, the hydraulic oil flows out through the drain hole.

In the oil discharge stage, the hydraulic pump continues to supply oil.

The piston moves to the left, and the pressure in the working chamber increases.

In the return stage, the hydraulic oil flows out through the drain hole.

Design and optimization of booster cylinders

The design of booster cylinders needs to consider factors such as cavity size, piston diameter, etc.

To ensure that sufficient pressure is provided in a short period of time.

For example, some designs incorporate hydraulic cylinder liner construction that increases the boost capacity.

By increasing the effective force area of the piston rod, resulting in faster response times and fewer defects.

In addition, modern booster cylinder systems may also be equipped with a closed-loop control system for more precise pressure control.

Application and effect of pressurized cylinder

The application of pressurized cylinder significantly improves the quality of die castings.

For example, in some designs, through local pressurization technology, problems such as shrinkage porosity and shrinkage porosity in thick-walled areas can be effectively solved.

So as to improve the overall strength and quality of castings. In addition, the rational design of the booster cylinder can also reduce energy consumption and improve production efficiency.

Haichen die casting machine manufacturer

Booster cylinders play an important role in the production of modern die casting machines.

And their design and optimization not only improve production efficiency,but also improve product quality and reliability.

Through the rational configuration and use of booster cylinders.

The limitations of traditional booster systems can be effectively solved and the needs of different materials and processes can be met.