The Advantages of Aluminum Casting Alloys are numerous. They include low melting point, good fluidity, high strength, corrosion resistant.

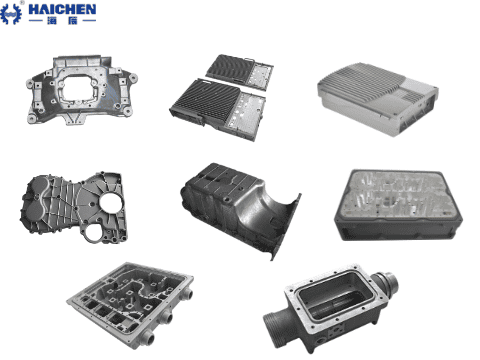

Today, aluminum alloy castings have become the preferred material in the field of high-pressure die casting, and are widely used in scenarios such as automobile engine cylinder blocks, gearbox housings, 5G base station radiators and consumer electronic device frames.

The following will analyze the reasons why this type of alloy dominates modern high-pressure die-casting production lines based on actual production needs.

The Advantages of Aluminum Casting Alloys

- Low Melting Point

- Excellent Fluidity

- Good Mechanical Properties

- Corrosion Resistance

- Lightweight Nature

- Recyclability

Low Melting Point

The melting point of aluminum alloy casting alloy is relatively low, usually between 600°C and 660°C. This feature allows the melting and casting process to be completed at lower temperatures. Compared with high melting point metals such as steel (which require high temperatures above 1500°C), the processing temperature of aluminum alloy is significantly lower, which directly reduces the energy consumption in the smelting process, thereby effectively controlling production costs.

Excellent Fluidity

Aluminum alloy casting materials have good fluidity in liquid state. This property enables the molten metal to fully fill complex and delicate mold cavities, thereby manufacturing parts with thin walls and precise structures. This advantage is particularly suitable for lightweight parts such as automotive engine parts and electronic equipment housings that have strict requirements on weight control and dimensional accuracy.

Good Mechanical Properties

Aluminum alloy casting materials have excellent mechanical properties. This type of material can provide sufficient strength and good deformation resistance. For example, some aluminum alloy castings can achieve a tensile strength of more than 300 MPa (equivalent to a tensile force of 30 kg per square millimeter) while still maintaining moderate flexibility. This property makes them particularly suitable for application scenarios that require both strength and deformation ability – for example, when parts need to withstand bending or extrusion, the material is not prone to breakage.

Corrosion Resistance

Another practical advantage of aluminum casting alloys is their corrosion resistance. When aluminum is exposed to air, a very thin but dense oxide film will naturally form on its surface. This oxide film can effectively isolate the external environment and prevent further oxidation or corrosion of the aluminum. Therefore, aluminum casting alloys are particularly suitable for scenes with high humidity or exposure to chemicals, such as shipbuilding, chemical equipment and other industrial fields that require long-term corrosion resistance. This feature not only extends the life of the material, but also reduces maintenance costs, making it a popular choice for engineers.

Lightweight Nature

Aluminum casting alloys also have a practical advantage – they are lightweight. With a density of only about 2.7 g/cm³, they are much lighter than metals such as iron (which has a density of about 7.87 g/cm³). This weight-saving property is particularly valuable in aerospace and automotive manufacturing, where engineers often need to strictly control the weight of parts. Choosing this material to make parts can not only improve fuel efficiency, but also optimize overall performance.

Recyclability

Aluminum casting alloys have excellent recyclability. These alloys can be melted down and reused repeatedly without significant degradation of their performance. This recycling feature not only saves mineral resources but also reduces waste generation. Taking automobile manufacturing as an example, recycled aluminum can be reused in the production of engines, wheels and other parts (the automotive industry accounts for 70% of recycled aluminum consumption). Compared with the production of new aluminum, the recycling process can save about 95% of energy consumption, effectively reducing the negative impact on the environment.

HAICHEN Aluminum Cookware Application Example

280X70 Aluminum Deep Fry Pan Case Study

The 280X70 aluminum deep fry pan developed by HAICHEN for cookware manufacturers fully demonstrates the comprehensive advantages of aluminum alloys:

Material Advantages Demonstrated:

- Excellent Thermal Conductivity: Aluminum’s rapid heat conduction ensures even heating of food, avoiding localized hotspots

- Lightweight Design: 1kg weight is 60% lighter than traditional iron pans, improving usability

- Corrosion Resistance: Surface treatment technology enhances anti-corrosion performance, extending product service life

Production Process Innovations:

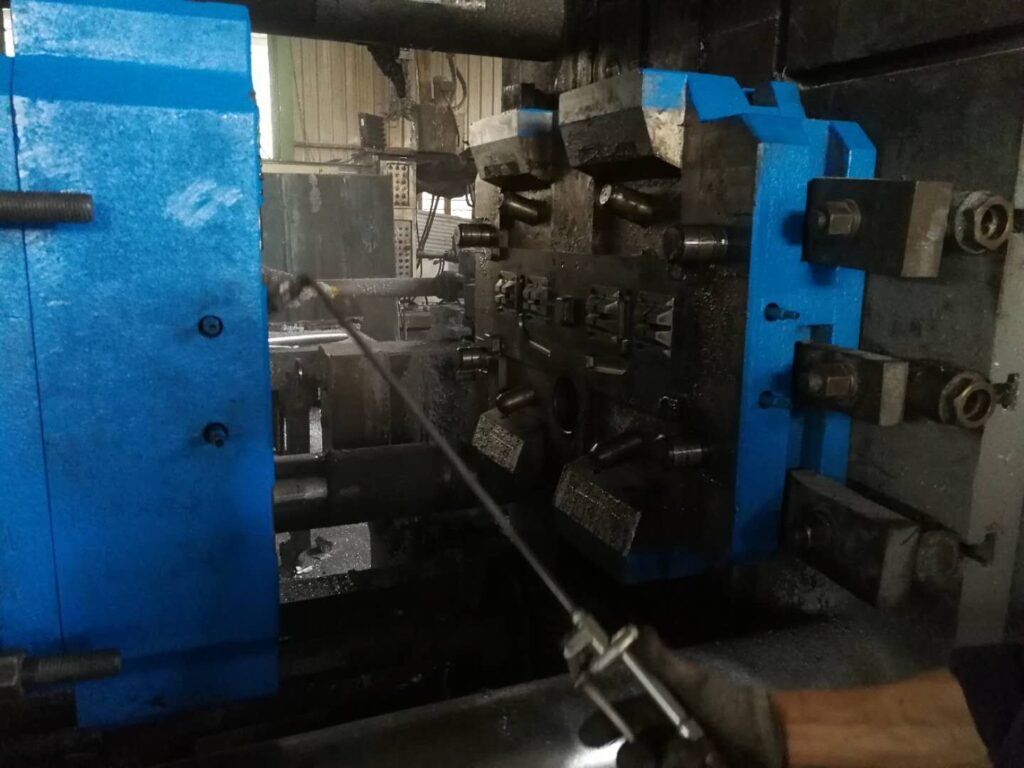

- Utilizes HAICHEN HCD-1600 cold chamber die-casting machine, achieving 45-second rapid cycle time

- Precisely controls the thickness difference between the 4mm bottom and 2.8mm side walls

- Mold thermal balance system ensures dense structure without defects

Performance Test Results:

- Heat distribution uniformity: ±3°C (industry standard ±5°C)

- Service life: Passed 100,000 durability test cycles

- Production efficiency: 1,500 pieces daily with 98.5% yield rate

Analysis of industry application cases

- Automobile manufacturing

- Electronics and communications

- Aerospace

- Industrial equipment

Automobile manufacturing

Lightweight components: engine block (30% weight reduction), body structure (Tesla integrated die-cast rear floor shortens production time to 45 seconds).

New energy three-electric system: battery housing (JDA1b heat-treatment-free alloy tensile strength exceeds 220MPa).

Electronics and communications

Heat dissipation module: 5G base station radiator uses high thermal conductivity to control temperature.

Electromagnetic shielding: The shell blocks radio frequency interference and improves equipment stability.

Aerospace

High-strength components: aircraft engine blades, satellite antenna brackets (specific strength 57, high and low temperature impact resistance).

Industrial equipment

Pressure-resistant components: hydraulic valve body, pump housing (pressure resistance of more than 50MPa).

Comparison with other die casting material performance

| Performance | Aluminum alloy | Magnesium alloy | Zinc alloy |

| Density (g/cm³) | 2.7 | 1.8 | 6.7 |

| Specific strength | 57 | 191 | 52 |

| Thermal conductivity (W/m·K) | 204 | 156 | 116 |

| Corrosion resistance | ★★★★☆ | ★★☆☆☆ | ★★★☆☆ |

| Cost-effectiveness | ★★★★☆ | ★★★☆☆ | ★★★★★ |

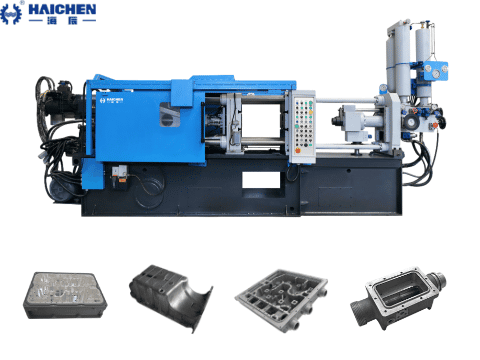

HAICHEN Die Casting Machines

Aluminum casting alloys are widely used in many fields such as automotive parts, LED lamp housings, and building components due to their excellent performance.

As a die-casting machine manufacturer with 20 years of professional experience, HAICHEN is committed to providing stable and efficient solutions. Our cold chamber die-casting machine series (HCD series) and hot chamber die-casting machine series (HCH series) cover a clamping force range of 500 to 30,000 kN, equipped with a servo energy-saving system and a multi-language operation interface, which can accurately adapt to the production needs of aluminum castings of different scales.

With the quality management system certified by ISO 9001 and CE, we ensure that each machine continuously outputs high-quality castings with uniform wall thickness and dense structure in fast cycle operation.

Aluminum alloy casting alloys have comprehensive advantages such as light weight, excellent casting performance, good thermal conductivity, corrosion resistance and recyclability. These advantages can be fully utilized when used with modern high-precision die-casting equipment.