Cold Chamber Die Casting Advantages include high precision, complex shapes, wide alloy range, high efficiency, and energy savings.

Cold chamber die casting stands out as a unique approach for crafting intricate and sizable metal parts, especially in industries where immense precision and detail are pivotal.

Unlike hot chamber die casting, this approach has its own set of cold chamber die cast advantages. Comprehending these benefits is essential for manufacturers who wish to refine their procedures and results.

This article is intended for manufacturers who wish to understand all the cold chamber die casting advantages that improve the quality and efficacy of the procedure.

Cold Chamber Die Casting Advantages

- High Precision and Tight Tolerances

- Complex Geometric Shapes

- Wide Range of Alloys

- High Production Efficiency

- Energy Efficiency

High Precision and Tight Tolerances

One of the main benefits of cold chamber die casting is gaining accuracy and precision. The molten metal is injected into the mold cavity at high pressure, which is a part of the die casting process. Uniform filling of the metal and a resulting part’s accuracy leads to lesser variability. Such accuracy is of grave importance to the automotive and aerospace industries, and electronics where components are required to fit to each other.

Complex Geometric Shapes

The ability to produce components with intricate details and designs is an advantage of cold chamber die casting. The molten metal will fill all the intricate details of the mold due to the high pressure applied. Thus, creating components like walls that are thin, and those that have internal and sliding cavities along with complex undercuts becomes simple. The importance of this accuracy is critical in the manufacturing of lightweight and complex in their structures components, including parts of engines and electronic housings.

Wide Range of Alloys

The use of alloys in cold chamber die casting is an added benefit. Unlike hot chamber die casting which is confined to low melting alloys like zinc and magnesium, cold chamber die casting accommodates high melting alloys like aluminum, copper, and brass. Manufacturers have the option to select the alloy which will best serve the application. The alloy may be chosen based on the needed strength, corrosion resistance, or high electrical conductivity.

High Production Efficiency

The production efficiency of cold chamber die casting is remarkably high. Due to the advanced level of automation, a high number of parts can be produced in a short time. After setup, each part can be molded in cycles as short as a few seconds. This efficiency is ideal for mass production as it greatly reduces costs while increasing productivity. Such high production efficiency is useful for industries with high product demand and strict timelines for delivery.

Energy Efficiency

Compared to other manufacturing processes, cold chamber die casting is relatively energy-efficient. The process requires less energy to heat the metal and inject it into the mold. Additionally, the high production efficiency means that fewer energy resources are consumed per part produced. This not only reduces operating costs but also has a positive impact on the environment by reducing carbon emissions.

Hot Chamber Die Casting vs. Hot Chamber Die Casting: Key Differences and Selection Criteria

| Parameters | Cold Chamber Die Casting | Hot Chamber Die Casting |

| Applicable Alloys | Aluminum, magnesium, copper (high melting point) | Zinc, tin, lead (low melting point) |

| Production Cycle | Medium speed (requires external melting) | High speed (integrated melting) |

| Equipment Cost | High (including independent melting furnace) | Low |

| High Temperature Resistance | No melt contact in the injection system, long service life | Parts susceptible to high temperature corrosion |

| Typical Applications | Automotive engine parts, aviation structures | Small connectors, decorative parts |

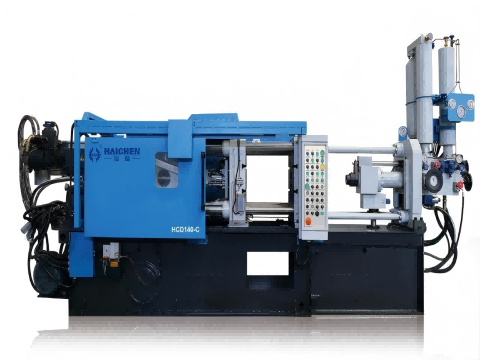

HAICHEN: Cold Chamber Die Casting Machine Manufacturer

HAICHEN is a cold chamber die casting machines leading manufacturers. With a proven track record in the industry, we provide an extensive portfolio of specialized machines.

HAICHEN do give their customers the added value of precision and reliability. They also saves the customers money with their energy efficient machines. After a sale, HAICHEN prove also saves the customers money. After a sale, HAICHEN provide training, maintenance, and technical support.

From small businesses to large manufacturers, HAICHEN has cold chamber die casting solutions for all commercial and industrial clients.

In conclusion, the advantages of cold chamber die casting are widely acknowledged. Other advantages are its ease of use, enable manufacturers a variety of alloys to choose from, the efficiency to produce at a large scale, and energy saving benefits.These benefits make it a preferred choice for many industries.