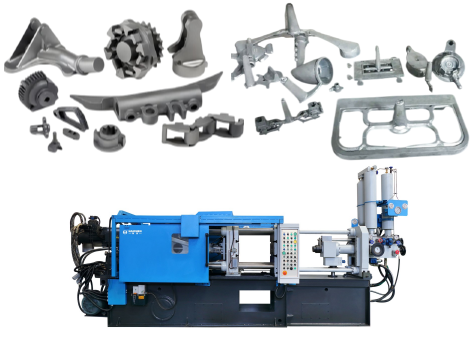

Why choose cold chamber die casting:

- Suitable for high melting point metals

- Precision and complexity

- Cost-effective

- Surface quality and dimensional stability

- Suitable for high-volume production

Choose cold chamber die casting is because it is a kind of high-efficiency equipment used for the manufacture of metal parts.

Especially suitable for the forming of metals with high melting points such as aluminum alloys, magnesium alloys, etc.

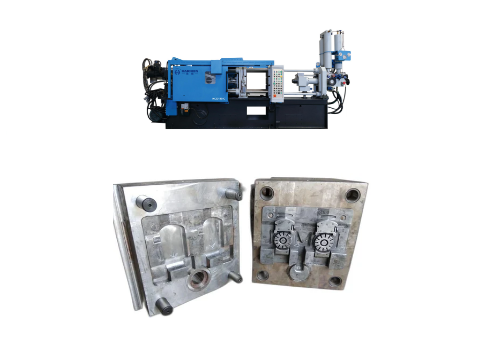

What Is Cold Chamber Die Casting?

Cold chamber die casting excels at crafting intricate and sizable components.

Unlike other die casting methods, it utilizes a separate furnace to melt high-melting-point metals like aluminum.

This separation allows for precise control over the metal during injection, resulting in complex shapes with exceptional strength.

When to Choose Cold Chamber

When working with Aluminum or Magnesium: These specific alloys are best suited for the cold chamber process.

When high pressures and high densities are required: The higher injection pressure leads to denser, stronger parts.

For large or complex parts: The process is well-suited for large, detailed components.

To avoid equipment corrosion: The separation of the melt and injection system from the equipment reduces the risk of corrosion.

Suitable for high melting point metals

Cold chamber die casting is particularly suitable for machining high melting point metals such as aluminum, copper, magnesium and zinc alloys.

These metals are susceptible to oxidation or damage to equipment due to high temperatures in hot chamber die casting.

While cold chamber die casting avoids these problems by introducing molten metal into the mold cavity from the outside, extending the life of the equipment and increasing production efficiency.

Precision and complexity

Cold chamber die casting enables the production of parts with complex geometries and high precision requirements.

The high-pressure injection process ensures dimensional consistency and accurate reproduction of the details of the part, which is important for applications that require tight tolerances and complex designs.

Strength and durability

Parts produced by cold chamber die casting are generally more robust and durable than those produced by hot chamber die casting.

This is because cold chamber die casting allows for finer grain structures and lower porosity, which enhances the mechanical properties of the material.

Cost-effective

Despite the high initial equipment investment, cold chamber die casting is a cost-effective manufacturing method in the long run due to its high production efficiency, good part quality, and low scrap rate.

In addition, maintenance costs are reduced because cold chamber die casting does not require frequent tool changes.

Surface quality and dimensional stability

Cold chamber die casting can produce parts with smooth surfaces and no parting line marks, and the part dimensions are more stable due to uniform mold cooling.

This is especially important for applications that require high-quality surfaces and dimensional consistency.

Suitable for high-volume production

Cold chamber die casting is suitable for high-volume production because it can complete more production cycles in a shorter cycle time, which improves overall production efficiency.

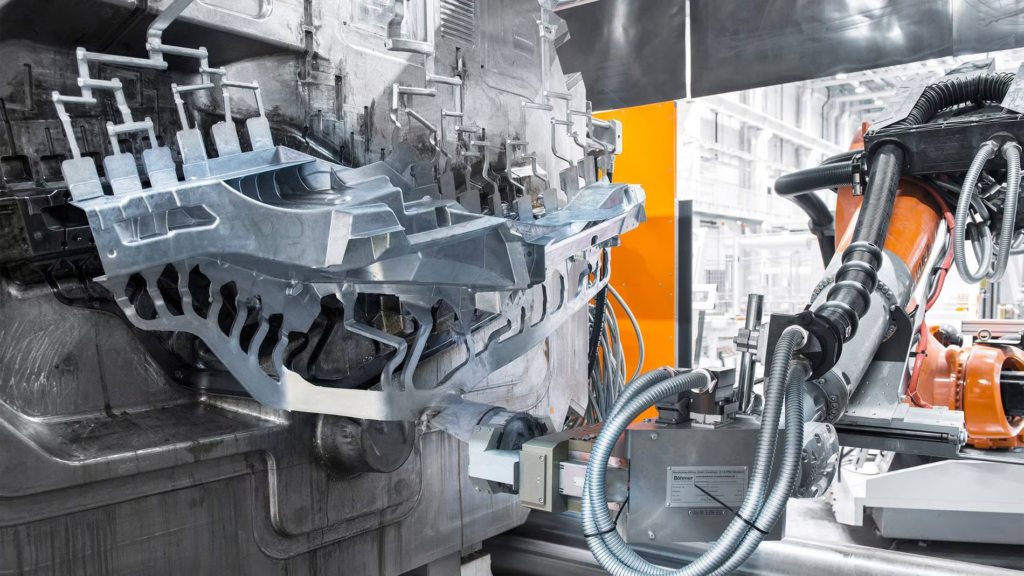

Choose cold chamber die casting——Automotive industry

- High precision and high quality

- Mass production and efficiency

- Material utilization

- Economic benefits

High precision and high quality

Cold chamber die casting machines are capable of producing parts with high dimensional accuracy and smooth and delicate surfaces.

Which are suitable for key components such as automobile engine blocks, gearboxes, and brake systems.

These parts not only have good strength and hardness, but also have a wall thickness of 0.5mm to 0.3mm.

Which meets the needs of modern automobiles for lightweight and high performance.

Mass production and efficiency

The mechanized production of cold chamber die casting machines has greatly improved production efficiency,

and one horizontal cold chamber model can produce 680 to 700 times a day, which significantly increases the production speed.

In addition, the cold chamber die casting machine has a high degree of automation, which reduces manual operation and improves production efficiency.

Material utilization

Cold chamber die casting machines can minimize material waste and improve material utilization during the production process.

Economic benefits

Due to the accurate size and smooth surface of the parts produced by the cold chamber die-casting machine, the demand for secondary processing is reduced and the processing cost is reduced.

In addition, the cold chamber die casting machine has a long equipment life, which reduces equipment replacement and maintenance costs.

Market competitiveness

The efficient production and high-quality products of cold chamber die casting machines enable automakers to produce high-performance auto parts at a lower cost, thereby increasing market competitiveness.

Choose cold chamber die casting——Aerospace industry

- High precision and high strength

- Production of complex shapes

- Economic benefits

High precision and high strength

Cold chamber die casting machines are capable of producing high-precision, high-strength structural parts and components for turbine blades, housings and structural components in the aerospace sector.

These parts need to withstand high temperatures and pressures under extreme conditions, and cold chamber die casting machines are able to provide the required material performance and precision.

Production of complex shapes

Cold chamber die casting machines are capable of producing parts with complex geometries, such as valves, brackets, and structural components, which play an important role in the aerospace sector.

Economic benefits

The cold chamber die casting machine can minimize material waste and improve material utilization during the production process.

Although the initial investment of the cold chamber die casting machine is high.

Its efficient production and high-quality products result in lower long-term operating costs and improved economic benefits.

Choose cold chamber die casting——Electronic Communication Equipment

- Application effect

- Economic benefits

Application effect

The cold chamber die-casting machine can produce miniaturized and integrated parts such as mobile phone shells, connectors, and radiators to meet the needs of the 5G era.

Economic benefits

By improving the precision and strength of the product, the cold chamber die casting machine helps to control the cost and improve the market competitiveness of the product.

Choose cold chamber die casting——Household appliances

- Application effect

- Economic benefits

Application effect

The cold chamber die-casting machine can produce key components such as motor housings, compressor components, radiators, etc., and improve the durability and energy efficiency ratio of home appliances.

Economic benefits

By improving production efficiency and product quality, cold chamber die casting machines help to reduce production costs and improve the market competitiveness of home appliances.

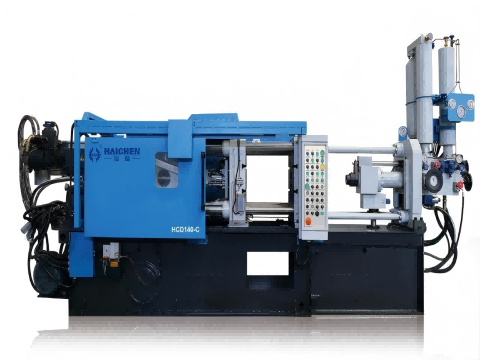

Choose cold chamber die casting from Haichen

The cold chamber die casting machine is a high-energy, clear and reliable equipment, especially suitable for manufacturing high-quality metal castings, which plays a vital role in modern industry.

Haichen die casting has multiple models for customers to choose, welcome to consult.