Are you looking for flaws and defects in the die casting industry? Do you know what the most common die casting defects are? What are the causes of these defects? How can you prevent them? Read this article carefully and you will get the answers and solutions you need.

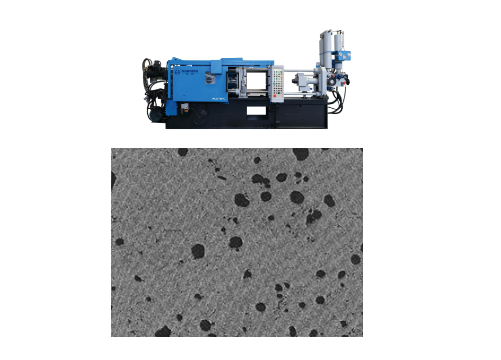

High Pressure Die Casting defects can occur in different production environments due to the special process requirements of each type of product.High Pressure Die Casting (HPDC) is a highly efficient metal casting process that is widely using in automotive, aerospace and electronics applications.

However, despite its high productivity and the ability to produce parts with complex geometries, the process also has some common defects.

Seven common die casting process defects

Let’s list some of the common High Pressure Die Casting defects:

- Porosity

- Shrinkage (Shrinkage)

- Condensation (Cold Shut)

- Inclusions (Inclusions)

- Cracks

- Oxides

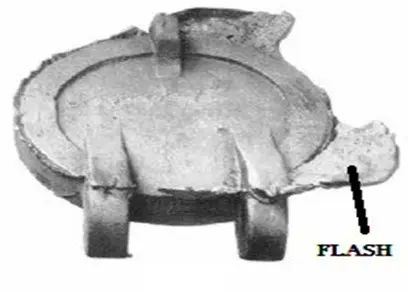

- Microstructural Defects

Porosity

This is one of the most common defects in HPDC.

Due to the rapid filling of the mould cavity with molten metal under high pressure, gases cannot escape completely, resulting in the formation of porosity.

These porosities are enlarged during the subsequent heat treatment process, thus affecting the mechanical properties and surface quality of the part.

Shrinkage (Shrinkage)

Due to the rapid cooling rate, the microstructure in the molten metal will shrink, resulting in the formation of shrinkage holes.

These defects are usually showing in thin-walled areas of the part and may weaken the overall strength of the part.

Condensation (Cold Shut)

When the liquid metal cools too quickly on the surface of the mould, a condensation layer may form.

This defect results in an uneven surface of the part and may affect its sealing and corrosion resistance.

Inclusions (Inclusions)

In the high-pressure die casting process, if the impurities in the mould material or pouring system are not removed in time, they may enter the molten metal and form inclusions.

These impurities will affect the mechanical properties and surface quality of the parts.

Cracks (Cracks)

Due to the combined effect of thermal stress and mechanical stress, high pressure die casting may appear cracks.

These cracks usually occur in the cooling process or subsequent heat treatment process.

Oxides (Oxides)

In the high-pressure die casting process, the metal liquid and mould surface contact may produce oxide inclusions.

These oxides will affect the surface quality and mechanical properties of parts.

Microstructural Defects (Microstructural Defects)

Due to the rapid cooling rate, the liquid metal in the solidification process may form a fine grain structure, which will affect the mechanical properties of the material.

In addition, external and thermal stresses may also lead to microstructural defects.

In order to reduce the occurrence of these defects, casting quality can be improved by optimising process parameters such as injection speed, mould temperature, cooling time and pressure.

For example, by adjusting the injection speed and mould temperature, haichen will reduce the formation of porosity and shrinkage holes can be effectively.

In addition, the use of vacuum technology can further reduce the generation of porosity.

Haichen’s high pressure die casting machines are solved by scientific process optimisation and advanced equipment technology, improving the quality and reliability of customers’ products.

How to remove porosity defects in high pressure die casting

Removal of porosity defects in high-pressure die casting is a complex problem that requires comprehensive consideration and treatment from a number of aspects.

Haichen die casting machine for you to provide some effective measures:

- Optimise the design of pouring system

- The use of vacuum assisted die casting technology

- Control process parameters

- Use of degassing techniques

- Improve mould materials and surface treatment

- Numerical simulation and optimisation

- Post-treatment measures

Optimise the design of pouring system

Reasonable design of gate and exhaust system is the key to reduce the porosity defects.

By optimising the location, size and shape of the gate, the flow state of the metal liquid can be effectively controlled and the chance of gas involvement can be reduced.

Set up exhaust holes in the mould to ensure that the gas can be discharged in time to avoid the formation of porosity in the casting.

The use of vacuum assisted die casting technology

Vacuum assisted die casting technology by applying negative pressure in the mould cavity.

The air inside the mould cavity will be extracted, thus reducing the formation of air holes.

We have proved this method able to significantly reduce the porosity in aluminium alloy die castings.

Control process parameters

Adjust process parameters such as pouring temperature, pressure and speed to ensure that the metal liquid can flow quickly and steadily during the mould filling process, and reduce the chance of gas entrapment.

For example, lowering the pouring temperature and pressure appropriately can reduce the chance of gas dissolving into the metal liquid.

Optimising the injection stroke and holding time ensures that the metal liquid is fully filling into the mould, reducing the chance of gas holes caused by unstable flow.

Use of degassing techniques

In the metal melting stage, use the method of blowing nitrogen or argon to degas the metal liquid.

Can effectively remove the gas dissolved in the metal liquid, thus reducing the formation of porosity.

Improve mould materials and surface treatment

Use mould materials with low gas absorption and treat the mould surface appropriately.

This will reduce the adsorption of gases on the mould surface, thus reducing the generation of porosity.

Numerical simulation and optimisation

Numerical simulation is carried out using computer-aided engineering (CAE) software.

Predict and analyse the location and cause of the formation of porosity defects.

And according to the simulation results to adjust the process parameters and mould design, in order to optimize the die casting process.

Post-treatment measures

For the castings that have produced porosity, we can repaire them by heat treatment, patch welding or machining.

For example, the use of hot isostatic pressure treatment can eliminate some of the porosity.

Through the comprehensive application of the above measures, it can effectively reduce the generation of porosity defects in the high-pressure die casting process and improve the quality and performance of castings.

How to remove condensation defects in high pressure die casting?

Removal of condensation defects in high-pressure die casting requires comprehensive consideration of process parameters, mould design and material properties and other aspects.

The following are some of Haichen’s effective solution measures:

- Optimise mould design

- Adjust the process parameters

- Improve material properties

- Improve the process flow

- Other measures

Optimise mould design

Increase cooling channels

By optimising the layout of the sprue and cooling system, the mould temperature can be effectively reduced, thus reducing the generation of condensation defects.

Use cold iron

Cold iron is set in the key parts of the mould to accelerate the cooling rate of the local area and prevent the formation of condensation defects.

Adjust the process parameters

Control pouring temperature and speed

Reduce the pouring temperature to avoid premature solidification of the metal liquid in the mould .

At the same time, adjust the filling speed appropriately to ensure that the metal liquid can flow evenly and fill the mould quickly.

Optimise the filling time

By adjusting the filling time, make the metal liquid flow more evenly in the mould and reduce the occurrence of condensation defects.

Improve material properties

Use high shear melt pretreatment technology

This technology can refine the grain structure and improve the microstructure, thus reducing condensation defects.

Selection of suitable alloy composition

Selecting alloys with a wide range of solidification temperatures can reduce the probability of condensation defects.

Improve the process flow

Vacuum die casting

The use of vacuum die casting technology can reduce the gas content, thereby reducing the generation of condensation defects.

forced convection mixing device

Use forced convection mixing device in high pressure die casting process.

This can improve the fluidity and temperature distribution of the metal liquid, thus reducing condensation defects.

Other measures

Use of mould release agents and lubricants

Ensure that the surface of the mould is smooth to reduce direct contact between the metal liquid and the mould, reducing the risk of condensation defects.

Regular maintenance and inspection of equipment

Ensure the equipment is in good condition to avoid condensation defects caused by equipment failure.

Through the above measures, Haicen can help you effectively reduce condensation defects in high pressure die casting and improve product quality and production efficiency.

How to remove inclusions defects in high pressure die casting

Removing inclusions defects in high-pressure die casting is a complex process that requires comprehensive consideration of a variety of factors and methods.

The following are some effective measures and methods:

- Strictly control the melting process

- Optimise the pouring process

- Use filtration techniques

- Control pouring temperature and speed

- Use advanced refining technology

- Mould design and maintenance

- Process optimisation and monitoring

Strictly control the melting process

In the melting process of aluminium alloy, we come to use hexachloroethane for de-nitrogenation purification to remove slag and impurities.

Haichen using special melting furnace can use vacuum degassing technology (such as RH treatment), by reducing the vacuum to reduce large-size non-metallic inclusions.

Optimise the pouring process:

During the pouring process, ensure that the moulds are clean and that the slag in the pouring ladle is thoroughly removed before pouring to avoid inclusions from entering the casting.

Use a suitable coating or spraying process to ensure that the coating adheres uniformly and firmly to the surface of the casting to prevent the ingress of inclusions.

Use filtration techniques

Most of the inclusions can be removed by filters before the liquid metal enters the mould.

For low pressure vacuum casting of high temperature alloys.

Haichen die casting machine adopts the method of lifting liquid tube immersed below the liquid surface to avoid foreign inclusions from being involved in the casting.

Control pouring temperature and speed

Control the pouring temperature to avoid excessive gas dissolution caused by too low a temperature.

Adjust the pouring speed to minimise turbulence and the introduction of oxides.

Use advanced refining technology

In steel treatment, vibrating electrode technology are able to control the behaviour of inclusions and thus improve the removal efficiency.

Argon blowing technique is using to effectively remove inclusions attached to bubbles at high flow rates.

Mould design and maintenance

Ensure that moulds are properly designed, use sand materials with good air permeability and add air permeability agents to promote gas discharge.

Clean the mould regularly to prevent inclusions due to mould contamination.

Process optimisation and monitoring

In the production process, through real-time monitoring and adjustment of process parameters.

Such as vacuum chamber pressure, argon blowing amount, etc., in order to optimise the removal effect of inclusions.

For the production of continuous casting billets, by controlling the secondary oxidation and non-steady state casting during the casting process.

Haichen high-end die casting equipment through the above measures, can significantly reduce the occurrence of inclusions defects in high pressure die casting.

Thus improving the quality of castings and production efficiency.