What are the components of die casting machine:

- Injection System

- Die Set

- Die Mounting & Clamping System

- Ejection System

- Other Key Components

A die casting machine has several key components, including an injection unit to force molten metal into the die, a die set with two halves that form the cavity and are mounted on platens.

A die clamping system to hold the die halves together under pressure, and an ejection system with pins to remove the solidified casting.

Other important parts include the die block, sliders, cores, and the overall structural assembly of the machine.

Die casting is a metal casting process widely employed for the mass production of high-quality, durable parts.

It delivers high dimensional accuracy in component production, making it ideal for precision-focused industries like automotive, aerospace and consumer electronics that demand consistent parts.

Whether you’re looking to manufacture complex shapes or achieve smooth surface finishes, die casting is an efficient solution for producing large quantities of metal parts while maintaining tight tolerances and exceptional performance.

The components of die casting machine

- Injection Unit

- Closing organization

- Hydraulic System

- Mold or Die

- Die Mounting and Clamping System

- Injection Organization

- Ejection System

Injection Unit:

- The injection unit is responsible for injecting molten metal into the mold. It consists of a furnace, a deburring device and a nozzle.

- The furnace heats the metal to a specific temperature and the nozzle delivers the molten metal into the mold.

Closing organization (Die Organization)

- The closing mechanism locks the mold during the injection process, stopping the mold parting surface from shifting during filling.

- Closing force (locking force) is a measure of the size of the die casting machine is a major parameter.

Hydraulic System

- The hydraulic system provides power and energy to the die casting machine to operate the injection unit and the closing mechanism.

Mold or Die

- A mold is a tool used in the die casting process to form the shape of a part.

- And a die usually consists of two parts: a fixed half-die and a removable half-die, which are closely matched during the injection process.

Die Mounting and Clamping System

- This system is responsible for mounting and closing the mold to ensure that the mold is able to withstand high pressure and remain stable during the injection process.

- It is responsible for mounting and closing the mold to ensure that the mold can withstand high pressure and remain stable during the injection process.

Injection Organization

- Liquid metal flows at regular intervals at a certain speed in a chamber to meet the energy requirements from the sprue to the mold cavity, and pressure is applied when necessary to ensure a continuous flow of the liquid metal.

Ejection System

- After the injection is complete, the exhaust system pushes the casting out of the mold for subsequent processing.

Auxiliary Equipment

- These include auxiliary devices for metal pouring, storage and mechanization, such as pouring systems, cooling systems, etc.

How to find the right die-casting machine manufacturer?

To ensure that you can obtain high-quality die-cast metal components, you need to find a manufacturer of die-casting machines that is experienced and has a good reputation in this field.

This will guarantee that the die-casting machine you purchase is always sturdy, reliable, and durable, and can produce precise die-cast parts.

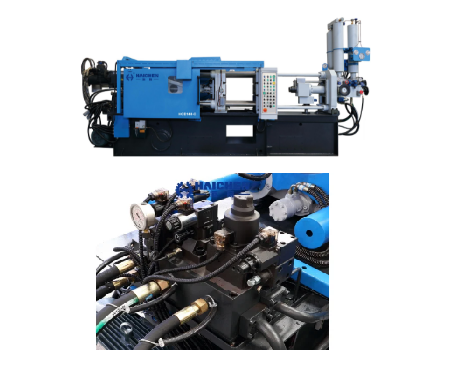

Haichen’s die-casting machine manufacturing plant is located in Ningbo City, China.

This place has one of the top ports in the country, enabling us to serve our customers more quickly.

The expert team of Haichen focuses on the efficient design and engineering of molds, with the aim of minimizing problems such as overflow.

We have a large and experienced engineering team with extensive knowledge and professional skills, capable of making precise adjustments to the manufacturing process of molds.

We are always ready to answer any questions, provide samples, and offer detailed data on our existing products and customized projects.

Haichen die casting machine supplier

Haichen is a manufacturer of die casting machines, offering both cold chamber and hot chamber die casting machines.

And Haichen’s die casting machines allow for the rapid production of complex parts, suitable for large-scale production.

The high metal injection rate and fast production cycle time increase overall productivity, making them ideal for high-demand production environments.

If there is any demand, welcome to consult us.