Cold chamber die casting machine price range from tens of thousands to hundreds of thousands of dollars.

Cold Chamber Die Casting Machine is a high-pressure equipment used for metal casting. Its main feature is to quantitatively feed molten metal from an independent holding furnace into the injection chamber (cold chamber), and then inject the metal into the mold through a hydraulic piston.

This die-casting method does not immerse the injection chamber and injection punch into the molten metal, but instead pours a certain amount of molten metal into the injection chamber through the pouring port before injection. Cold chamber die casting machines are commonly used for processing non-ferrous metal materials such as aluminum alloys, magnesium alloys, and copper alloys.

Cold chamber die casting machine price range from tens of thousands to hundreds of thousands of dollars. The cold chamber die casting machine price range varies depending on many factors, we will discuss about it from below 4 main factors. When purchasing, you need to choose the appropriate model according to your specific needs.

- Technical parameters and configuration

- Material cost and processing demand

- Market demand and economic environment

- Maintenance and after-sales service costs

Technical parameters and configuration

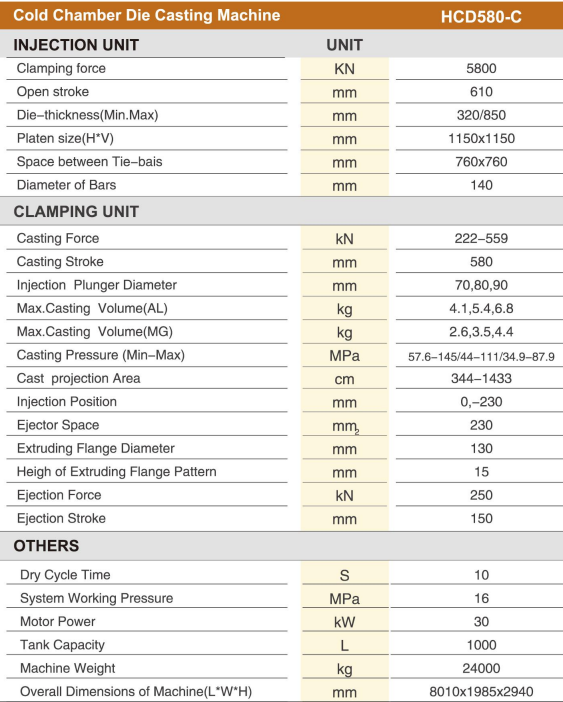

The machine price closely relates to machine parameters and configuration. Such as clamping force, die thickness, platen size, casting force and others. These parameters are the key factors to decide the machine performance. The higher the performance, the higher the price. Let’s take examples as follow:

Locking force

The bigger the locking force, the higher machine price. For example, the locking force of a 90ton cold chamber die-casting machine is 900kN, while the 580T machine model can reach up to 5800kN. It’s easily to find the the latter 5800kn locking force has significantly increase in price. Because due to it’s more complex machine structure and production material requirements.

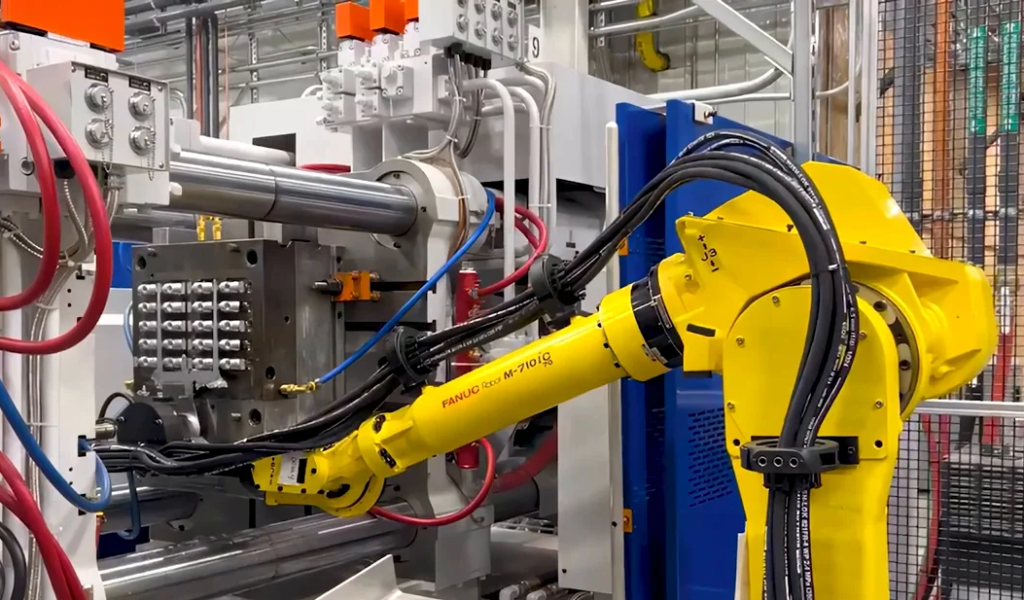

Automation level

When die casting machines equip with PLC control systems or automatic robots. These auxiliary equipments can improve the production efficiency. But these also raise up the cold chamber die casting machine prices.

Material cost and processing demand

The production of cold chamber die casting machines may involve the use of multiple materials and energy, such as electricity, cooling water, etc. These costs will significantly affect the total cost.

Raw material prices

The market price fluctuations of metals such as aluminum alloys and magnesium alloys directly affect equipment costs, especially for high melting point materials (such as copper) that require higher performance die-casting machines, further increasing costs.

Material processing adaptability

Different materials have different requirements for equipment. For example, aluminum alloys require anti oxidation design, while magnesium alloys require precision temperature control systems. These customized configurations increase equipment prices.

Material utilization rate

Thin walled castings require more complex flow channel system design, which saves materials but increases mold and process control costs.

HAICHEN’s Approach to Delivering Competitive Value

HAICHEN balances advanced performance with a sensible cold chamber die casting machine price to offer exceptional value.

- Optimize Investment for a High-Volume Parts Producer case

- HAICHEN Advantage of Engineered for Performance and Efficiency

Optimize Investment for a High-Volume Parts Producer case

A manufacturer needed to replace an old, slow machine for automotive parts. They received quotes ranging from very low to very high. HAICHEN proposed a 600-ton machine with a hybrid servo system. While not the cheapest, its energy efficiency cut power costs by 30%. Its precision and speed also increased yield by 8%. Within 18 months, the savings covered the price difference. The client gained a more competitive production line.

HAICHEN Advantage of Engineered for Performance and Efficiency

Our philosophy is to build machines that make our clients more profitable. We optimize the cold chamber die casting machine price by using reliable components in a smart design. We focus on features that boost productivity and reduce operating costs. Our global service network ensures your investment is protected. With HAICHEN, you pay for a productivity tool, not just a machine.

Market demand and economic environment

Industry demand growth

The lightweighting of automobiles and the precision of 3C products are driving the demand for cold chamber die-casting machines. The global market size is expected to reach 2.433 billion US dollars in 2024, and strong demand is driving up prices.

Raw materials and exchange rate fluctuations

Fluctuations in the prices of bulk commodities such as pig iron and aluminum ingots affect manufacturing costs, while enterprises with a high proportion of exports also need to cope with exchange rate risks.

Customized demand

The automotive industry’s demand for integrated die-casting islands (including peripheral equipment) increases overall procurement costs by 20% -30%.

Maintenance and after-sales service costs

Maintenance cost difference

The initial purchase cost of the cold chamber die-casting machine is high, but the maintenance cost is low during normal operation; However, the hot chamber machine has higher long-term maintenance costs due to the rapid wear and tear of high-temperature components.

After sales service fees

After sales service fees account for approximately 0.5% -0.9% of equipment revenue, including labor, accessories, etc. Manufacturers may include this implicit cost in the selling price.

Application of energy-saving technology

Energy saving models using servo motors (with a 90% increase in energy efficiency) have higher initial costs, but can reduce energy consumption and maintenance expenses in the long run.

Haichen cold chamber die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

The question “How much is a cold chamber die casting machine?” has a complex answer. The price depends mainly on size, performance systems, and automation level. However, the true cost is the Total Cost of Ownership. Evaluating energy use, productivity gains, and long-term reliability is crucial. As demonstrated by HAICHEN, a slightly higher initial investment in a well-engineered machine often leads to much lower costs per part and a stronger competitive position. Make your decision based on lasting value and partnership, not just the initial cold chamber die casting machine price.

When you have any demand of cold chamber die casting machine, feel free to contact us.

We will help select suitable machine model according to your specific demand with our professions.