Choosing die casting products for their high precision, strength, durability, and cost-effectiveness in high-volume production.

Die casting is a core manufacturing process for mass-producing metal parts. It forces molten metal under high pressure into a precision steel mold, quickly forming parts with complex shapes, accurate dimensions, and high consistency.

This process offers clear benefits in lightweight design, structural strength, and low per-part cost. It is essential in industries like automotive, electronics, and appliances.

This article explains the key advantages of die casting and how precision engineering creates value for manufacturers.

The main reasons for choosing die casting products

- High Precision and Consistency

- Strength and Durability

- Wide Range of Materials

- Cost-Effective for High-Volume Production

- Aesthetic and Functional Benefits

High Precision and Consistency

One of the main advantages of die casting products is the high precision and consistency. Accuracy with tight tolerances along with intricate and complex geometries is possible with die casting because parts produced are dimensionally aortic. This is vital precision in parts manufacturing for the automotive and aerospace with electronics industries where precision and reliability is a necessity.

Strength and Durability

Strength and durability is the die cast parts hallmark trademark. The method uses high pressure which injects molten metal, resulting in a dense and uniform structure. This also makes die cast parts wear and tear resistant and enables them to take on high levels of stress and impact. The products are then die cast for the most appropriate use in situations demanding components which are tough and withstanding.

Wide Range of Materials

The die casting materials are aluminum, zinc, magnesium and copper alloys which are many. There is a distinct set of properties for each material which makes them useful for die casting parts. Aluminum is know for being lightweight as well as corrosion resistant which makes it usable for parts in vehicles. Moreover, zinc is also know best for precision components because of having excellent dimensional stability and surface finish.

Cost-Effective for High-Volume Production

It is particularly economical for high volume production runs. Initial setup costs are offset by the ability to manufacture parts on a large scale. Once the mold’s set, thousands of parts can be make with consistent quality at a low cost per unit. Enhanced production effectiveness of primary operations along with the lowered need for secondary processes make die casting economically favorable for bulk production.

Aesthetic and Functional Benefits

Die casting surfaces can be polish to a brilliant shine and intricate features added to them which makes them useful both for their functions and for their forms. Smooth and complex parts increase the die casting’s capability to replace supplementary machining, finishing processes improving productivity. Enhanced die cast surfaces and intricate appearances elevate the overall value of the product while improving its utility.

Die Casting vs. Other Processes: Why is Die Casting Better?

| Process | Application Scenarios | Disadvantages | Alternative Value of Die Casting |

| CNC Machining | Small-Batch, High-Precision Parts | Material Waste >60%, Long Cycle Time | 50%+ Cost Reduction for Production of 10,000+ Parts |

| Injection Molding | Plastic Parts | Low Strength, Poor Heat Resistance | 3–5x Increased Lifespan of Metal Parts |

| Sand Casting | Single-Piece Production of Ultra-Large Parts | Poor Accuracy (Tolerance ±1mm) | 10x Increased Dimensional Accuracy, No Surface Treatment Required |

Die Casting Machine Manufacturer

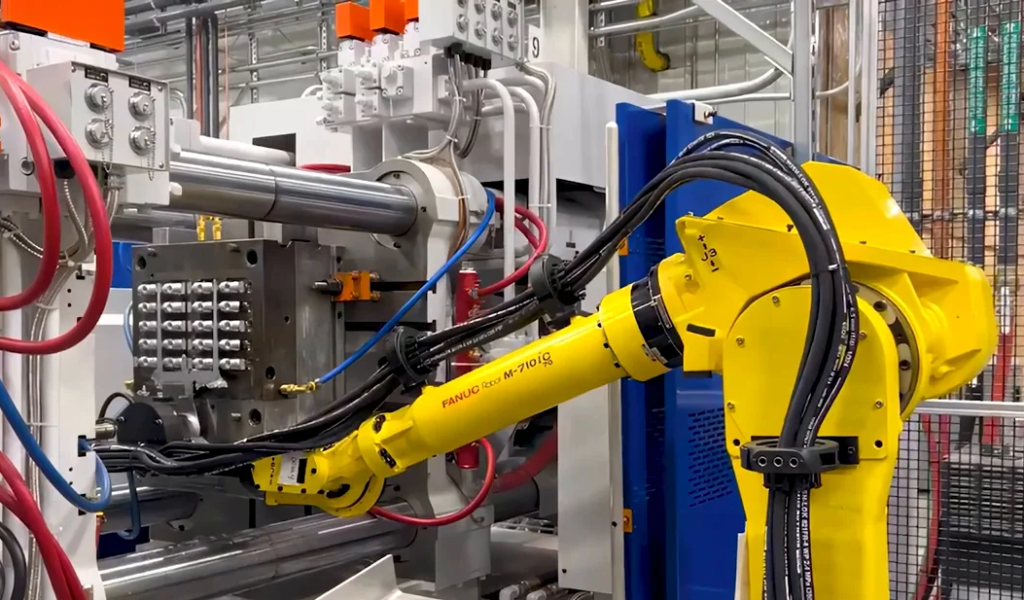

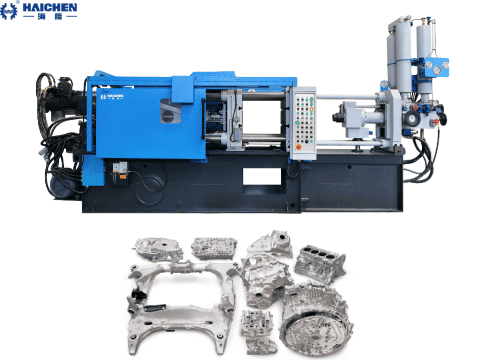

HAICHEN is a distinguishable brand within die casting industries, boasting quality and reliability in their machines. Their devices undergo rigorous testing through advanced industrial technology and construction.

HAICHEN offers a variety of die casting machines, both cold and hot chamber, to cater to different production requirements. In addition, he provides complete after-sales service and customer training relative to their machines for best investment value.

HAICHEN Die – Casting Products

Aluminum Pots

HAICHEN has extensive experience in manufacturing high – quality aluminum pots. These pots are known for their excellent thermal conductivity and even heat distribution, making them ideal for cooking applications. Our aluminum pots are design with precision and durability in mind, ensuring long – lasting performance.

Road Studs

HAICHEN also specializes in producing road studs for traffic management. These studs are design to withstand harsh outdoor conditions and provide clear visibility for drivers. Our road studs are manufactured using advance die – casting techniques, ensuring high – quality and durable products.

Medals

For commemorative and decorative purposes, HAICHEN offers custom – made medals. These medals are crafte with intricate designs and high – quality finishes, making them suitable for awards, recognitions, and special events. Our medals are produced using precision die – casting, ensuring each piece is unique and of the highest quality.

HAICHEN Case: Turning Advantages into Results

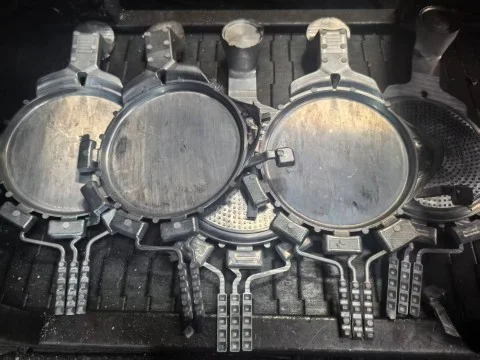

HAICHEN die casting machines turn these process advantages into real productivity. Take the production of a 280mm aluminum fry pan as an example. The part has thin walls and a deep cavity, demanding precision, surface quality, and fast cycles.

- Challenge: Ensure perfect filling of thin walls (2.8mm) without defects, maintain even wall thickness and high surface finish, and achieve efficient mass production.

- HAICHEN Solution: A HAICHEN 650-ton cold chamber machine was use. Its high-response servo injection system ensured smooth, rapid filling with an optimized multi-stage profile. The smart mold temperature control system maintained thermal balance for even solidification.

- Result: The product yield stabilized at over 98.5% with a cycle time under 45 seconds. The castings were dimensionally accurate with excellent surface quality. This fully demonstrates die casting’s combined advantages in precision, strength, efficiency, and cost, giving the customer strong market competitiveness.

Gaining die casting products provides a multitude of advantages, such as high strength and precision, low cost during mass production, a variety of materials, and superior functional and aesthetically pleasing features.