Die Casting Mold Material Cost is influenced by factors like material selection, mold complexity, size, production volume, and market conditions.

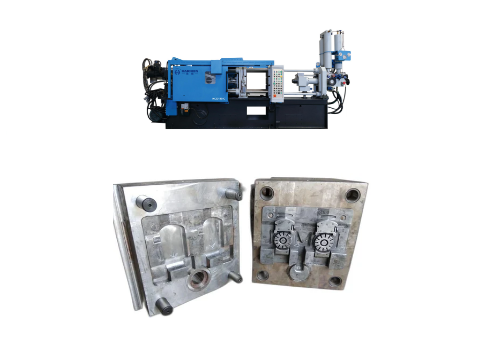

Die casting is a specific industrial process for making metal components that uses precise methods to produce complex parts with immediate repeatability. One major factor influencing die casting costs is the material selected for the die.

Knowing the cost parameters for the material of the molds is crucial for the manufacturers to streamline their workflows and maximize profits.

In this article, we will explore the factors that influence die casting mold material cost and provide insights on how to manage these costs effectively

Factors Influencing Die Casting Mold Material Cost

- Material Selection

- Mold Complexity

- Mold Size

- Quantity of Parts

- Market Conditions

Material Selection

The decision on what material to use for a die casting mold can considerably influence the costs involved. Typical mold materials include some steel alloys like H13, P20, and S7. These materials are selected for their strength, thermal stability, and wear resistance. The market conditions and the specific alloy have a direct impact on the availability and price of these materials. For example, H13 steel offers excellent thermal stability, making it a good choice for precision durable molds, although it can be more costly than other steels.

Mold Complexity

The intricacy of the mold design affects the material quantity and cost. The more intricate the design, the more material it requires and it involves more sophisticated advanced manufacturing methods like precision machining, EDM, and other Electrical Discharge Machining techniques. These methods of mold fabrication raise the material expenses for the mold and, therefore, increase the total expense for mold fabrication.

Mold Size

The increase in the size of the mold makes them cost more than smaller molds. This increase in cost occurs due to the increase of material for the mold. The mold size is directly proportional to the size of the component to be manufactured. For oversized components such as automotive engine blocks, the cost of mold materials is very high.

Quantity of Parts

The amount of parts to be made from a mold also affects the mold material cost. With high-volume production, mold material costs can be justified as the cost can be amortized over a higher volume of parts. Low volume production, however, may require more cost-effective mold materials to be profitable.

Market Conditions

Market conditions such as price of raw materials, supply and demand, and even political conditions can also affect the cost of mold materials. To manage costs, manufacturers have to keep track of market conditions.

Managing Die Casting Mold Material Cost

- Optimize Design

- Material Selection

- Efficient Machining Processes

- Supplier Relationships

Optimize Design

The mold design can also be optimize to reduce the amount of materials required, such as identifying weak points using simulation software.

Haichen developed a large die-casting mold for an automotive parts manufacturer. Through simulation analysis, they redesigned the cooling channels and support structure, successfully reducing the mold weight by 18% while maintaining the same service life, thus significantly reducing material costs.

Material Selection

The mold can be design with the part’s requirements in mind and balance between performance and cost efficiency. For example, some molds may not require high precision or durability, therefore using lower cost materials makes molds more economical.

Haichen implements modular mold design, dividing molds into standard modules and customized modules. Standard modules adopt a universal design, enabling mass production and reducing unit costs; customized modules are optimized for specific product requirements.

Efficient Machining Processes

Through high speed and precision machining, mold production can be lowered and even material waste reduced.

For high-volume, high-precision products, such as automotive engine parts, Haichen recommends using high-quality imported mold steel to ensure mold life and stability; for small-volume, ordinary-precision products, it recommends using high-quality domestic mold steel with a better cost performance.

Supplier Relationships

Developing effective supplier relations can lead to improved pricing and more consistent supply chains. Cost management through long-term contract negotiation can also be achieve during volatile market conditions.

Haichen implements a material grading strategy based on the working conditions and wear levels of different parts of the mold. High-performance materials are used in key parts such as the mold core and slider, while conventional materials are use in auxiliary parts such as the template.

The Cost-Amplifying Effect of Heat Treatment Processes

Although the cost is small, the impact is significant.

- Although heat treatment contributes to only 5% of a mold’s total cost, it dictates 80% of the mold’s performance over its useful life. Conventional heat treatment under vacuum costs 25% more, but benefits mold life by 40% to 400%.

The Cost of Process Errors

- Sustained quenching deformation can lead to extensive it costs above 200,000 yuan ($200,000 ) a medium-sized mold).

The Link between Mold Design Complexity and Material Cost

Material Selection Strategy

- Approach Strategy Due to high cost and high toughness material, complex molds should prioritize reduced cracking risk of high toughness materials such as Dievar. This increases material costs, but reduces scrap rates.

Cost Optimization Paths

- Simple mold construction: Domestic H13 + Conventional heat treatment → Control initial investment.

- Complex molds: Dievar + vacuum heat treatment → Cost amortization from extended lifespan benefits.

HAICHEN: Die Casting Machine Manufacturer

When it comes to die casting machines, HAICHEN is a die casting machine manufacturer well recognized for the reliability and quality of his machines. HAICHEN’s machines are equip with modern technology and are constructed to endure industrial workloads.

Our company is engage in the production of several types of die casting machines, including cold chamber and hot chamber models, to satisfy different production requirements. In addition, HAICHEN provides complete after-sales service, including technical support, supply of spare parts, and training to maximize utilization of the investment.

Knowing the parameters that drive costs for die casting mold materials is key in optimizing workflow and overall profitability. By careful planning for mold design, right material selection, machining process selection, and strengthening supplier collaborations, manufacturers can effectively control costs.