The Aluminum Die Casting process involves injecting molten aluminum into a steel mold under high pressure to create high-strength parts.

Aluminum die casting allows manufacturers to efficiently produce complex metal parts with precise dimensions and smooth surfaces.

Operators pour molten aluminum alloy into a special steel mold and use high pressure to quickly cool the metal into shape.

Because this process can consistently produce lightweight, durable parts with extremely small tolerances. It is widely used in products such as automotive parts, aircraft components and everyday electrical appliance housings.

Aluminum Die Casting process

Aluminum die casting plays a key role in the automotive, aerospace and consumer electronics industries. The core requirements of these industries for parts are clear: structural strength and lightweight design must be achieved. Next, we will explain the specific operation process and technical points of aluminum die casting step by step.

- Mold Preparation

- Metal Melting and Injection

- Cooling and Solidification

- Ejection and Trimming

- Post-Processing

Mold Preparation

In the aluminum die-casting process, mold preparation is the first step. The operator needs to use non-corrosive detergent and soft brush to thoroughly clean the mold surface. Ultrasonic deep cleaning can be used for complex structural parts. After cleaning, it needs to be blown dry with compressed air to ensure that there is no residual moisture.

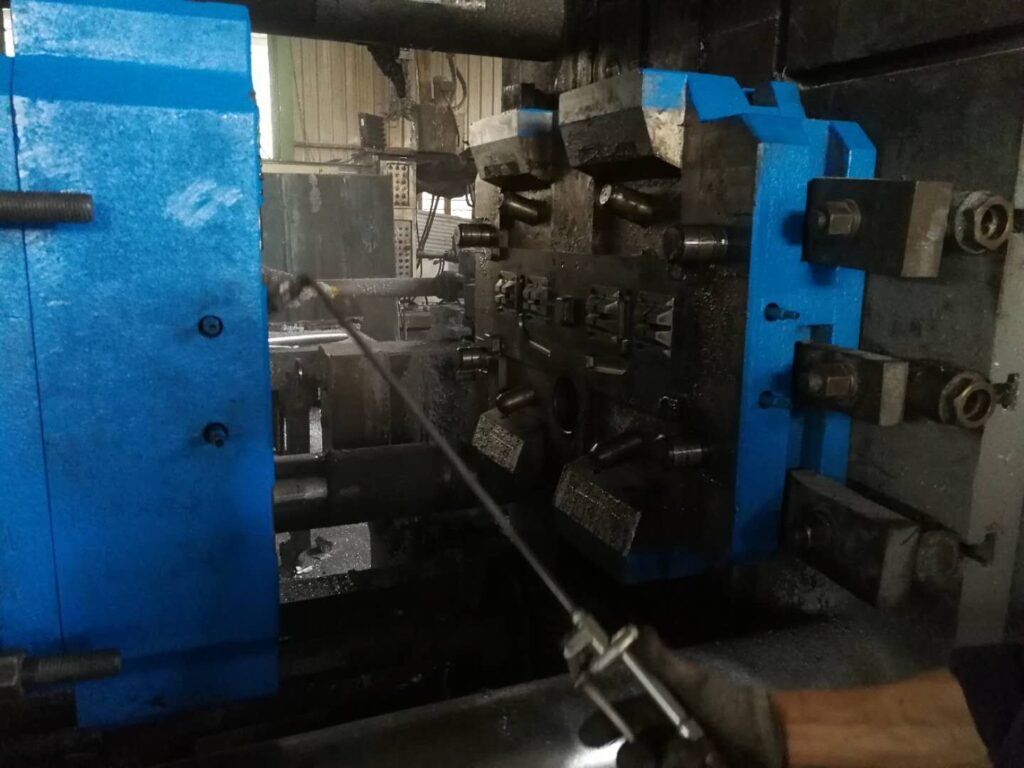

Next, evenly apply special grease (such as sodium-based grease) on the moving parts such as guide pins . And ejectors to form a thin layer of oil film to prevent impurities from mixing and affecting the accuracy. The mold usually consists of two parts: the fixed mold (also known as the cover mold) on the fixed side. And the movable mold (also known as the top mold) on the moving side, both of which are positioned by precision guide pins.

Before closing the mold, it needs to be preheated to about 250℃ to reduce the thermal shock when the molten aluminum is injected. And at the same time check whether the ejection mechanism is smooth. Finally, the cavity surfaces of the fixed mold and the movable mold need to fit completely to form a casting space that meets the design standards.

Metal Melting and Injection

The operator first puts the solid aluminum alloy ingot into the furnace for heating. And uses precise temperature control technology to completely liquefy the metal. The melting temperature must be strictly controlled between 660°C and 710°C (about 1220°F to 1310°F). Which ensures that the aluminum alloy maintains ideal fluidity and chemical composition stability.

The liquid aluminum is then transferred to the injection chamber of the die casting machine by the automated pouring equipment. The operation team drives the molten metal through the high-pressure system. And injects it into the pre-set mold cavity at a speed of up to 100 meters per second.

This high-speed and high-pressure coordination mechanism has two core functions:

- Complete filling: Forcing the metal to penetrate every tiny corner of the mold. Even thin-walled structures with a thickness of less than 1 mm can be accurately formed;

- Reduce defects: The high-pressure environment suppresses the generation of bubbles. And significantly improves the structural density and mechanical strength of the casting.

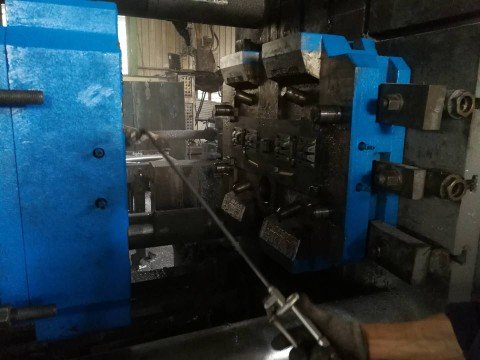

The entire process is achieved through a cold chamber die casting machine with an injection pressure of more than 10,000 psi (about 69 MPa). The mold is sprayed with a release agent before metal is injected. Which prevents the aluminum liquid from adhering and optimizes the metal flow trajectory. After the injection is completed, the aluminum liquid cools and shapes in the mold. And the operator removes the initial casting through the hydraulic ejection system and enters the subsequent finishing stage.

Cooling and Solidification

When molten aluminum is injected into the mold cavity at high speed, the cooling process starts immediately. The mold is embedded with an efficient heat dissipation structure, and a circulating water cooling channel or an external jet system is usually used to accelerate the cooling.

Engineers must precisely control the cooling rate – usually maintaining the mold temperature in the range of 150-250℃, which can ensure that the aluminum liquid solidifies evenly within a few seconds.

This link is crucial to product quality: too fast cooling may cause pores, while too slow cooling will cause shrinkage and deformation, and these defects will directly affect the structural strength of the part.

To optimize the efficiency of heat conduction, modern molds are equipped with intelligent temperature control loops, which dynamically adjust the cooling intensity by real-time monitoring of temperature changes in different areas.

Ejection and Trimming

When the aluminum is completely solidified in the mold, the worker separates the upper and lower molds and pushes the molded part out with a pin. At this point, the part is usually still connected to the runner and feed port (these are the channels for the aluminum to flow into the mold).

Next, the worker needs to cut off these excess parts, which can be done with hand tools (such as files, belt sanders) or automatic equipment.

This step directly affects the final shape and surface flatness of the part.

Post-Processing

After the part is formed, it needs to be processed later:

- Surface treatment: remove burrs by grinding or shot blasting, and remove oxide scale by sandblasting to ensure a smooth surface.

- Performance enhancement: Some parts need to be heat treated. For example:

- Annealing treatment: eliminate internal stress and improve dimensional stability

- Solution aging: heating the part to about 500℃ and then cooling it quickly can increase the hardness by more than 30%

- Protective treatment: use anodizing to form a protective film, or spray paint/powder coating to enhance corrosion resistance.

Advantages of Aluminum Die Casting

Aluminum die-casting technology shows multiple advantages in practical applications:

- Balance of lightweight and high strength

- Accurately shaping complex structures

- Efficient mass production capabilities

Balance of lightweight and high strength

Aluminum die-casting performs well in reducing weight while maintaining sufficient structural strength. This feature is particularly important in the automotive and aerospace fields – these industries often need to improve overall performance by reducing the weight of parts.

Accurately shaping complex structures

The process can accurately control the size of parts with extremely small tolerances, and even complex parts can be formed in one go. This means that designers can boldly adopt more precise geometric structures without worrying about production feasibility.

Efficient mass production capabilities

When large-scale production is required, the efficiency advantage of aluminum die-casting is particularly obvious. A set of molds can produce thousands of standard parts per hour. This large-scale production capacity significantly reduces the manufacturing cost of a single part.

Process Monitoring and Quality Control

To stably produce high-quality aluminum die castings, systematic process monitoring and quality control must be implemented during production. This ensures parameters at each stage remain optimal, allows for rapid identification and correction of deviations, and guarantees consistent product quality while reducing defect rates in mass production.

- Real-Time Monitoring of Key Process Parameters

- Process Capability Analysis and Statistical Process Control (SPC)

- In-Line Inspection and Defect Prevention

Real-Time Monitoring of Key Process Parameters

Modern die casting machines can collect and record core data for every shot in real time. This includes molten aluminum temperature, injection speed and pressure profiles, mold temperature, and cycle time. By setting tolerance limits for these parameters, the system can trigger an immediate alarm upon deviation, preventing batch defects. For example, an abnormal drop in peak injection pressure may indicate plunger tip wear or a hydraulic leak, signaling the need for prompt maintenance.

Process Capability Analysis and Statistical Process Control (SPC)

By collecting production data over the long term, the process capability index for critical quality characteristics (e.g., key dimensions, part weight) can be calculated to assess the stability and precision of the production process. Using statistical tools like control charts for monitoring allows for intervention when a process shows a trending drift, even before rejects are produced, enabling preventive quality control.

In-Line Inspection and Defect Prevention

Advanced die casting cells can integrate in-line inspection equipment such as vision systems, real-time X-ray imaging, or weight sorters. These can perform rapid checks on every casting, automatically identifying and rejecting parts with surface defects, internal porosity, or incorrect weight. This 100% in-line screening not only guarantees outgoing quality but also generates data that can be traced back to process parameters, helping engineers pinpoint the root cause of defects and optimize the process.

HAICHEN: Die Casting Machine Manufacturer

In the field of die casting machines, HAICHEN is a trustworthy manufacturer. We provide a variety of die casting machines, including cold chamber die casting machines, hot chamber die casting machines, etc. to meet your different production needs.

Our equipment combines mature and reliable technology, solid structure, and is designed to meet the requirements of long-term high-intensity use in industrial environments. In order to ensure that the products you purchase can operate stably and maximize their value, we have established a complete after-sales support system. This includes timely technical consultation and guidance, sufficient spare parts supply, and professional operation and maintenance training services.

HAICHEN Equipment Case for Demanding Production

An automotive parts supplier needed to produce large, thin-walled aluminum transmission housings with extremely high requirements for leak-tightness and strength. They selected a HAICHEN 880-ton cold chamber die casting machine equipped with an optional vacuum system. This solution effectively reduced gas entrapment in the cavity, significantly improving the internal density of the castings. Simultaneously, the machine’s high-rigidity clamping system and precise injection control ensured the stability of the large mold under high-pressure injection and consistent filling, maintaining the product yield rate above 95% and meeting the automaker’s stringent standards.

Aluminum die casting is an important method for producing lightweight and high-strength metal parts in the manufacturing industry. By mastering the core operation links, manufacturers can effectively adjust the production process and thus improve product quality.