Advantages of Zinc Die Casting make it an efficient, cost-effective, and reliable method of metal processing.

Zinc die casting offers a combination of high strength and hardness, excellent dimensional accuracy, good corrosion resistance, and thin-wall casting capabilities for complex designs.

Its low melting point contributes to faster production cycles, reduced energy costs, and extended die life, while the excellent as-cast surface finish minimizes machining needs.

Furthermore, zinc is highly recyclable, and the process can reduce labor costs by casting complex parts as a single unit.

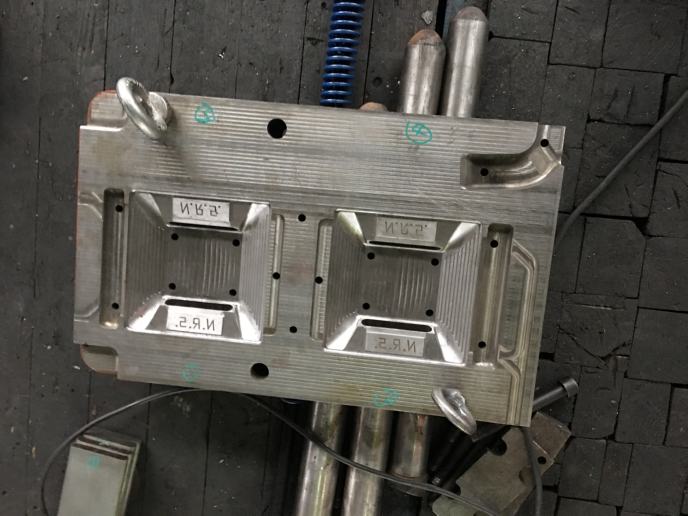

High-precision and complex shape manufacturing capabilities

Zinc alloy die casting is capable of producing parts with complex geometries and thin-walled structures while maintaining high accuracy and tight dimensional tolerances.

For example, zinc alloy die castings can achieve a tolerance range of ±0.005 inches (about 0.127 mm), which is critical in many applications.

Mechanical Advantages

Zinc alloys have excellent strength, toughness, and wear resistance, making them suitable for components that require high strength and durability.

In addition, zinc alloys have better tensile strength and fatigue resistance than many other cast alloys.

Cost Advantage

Zinc is a relatively inexpensive metal with a low melting point that results in lower die temperatures, which reduces energy consumption and production costs.

In addition, zinc alloy die castings usually do not require additional machining, reducing follow-up costs.

Surface quality and post-processing flexibility

Zinc die castings are known to have a smooth surface and are easy to apply surface treatments.

Such as plating, painting, or powder coating, thus improving their aesthetics and corrosion resistance.

This surface treatment capability makes zinc die castings widely used in the automotive, electronics, and consumer goods industries.

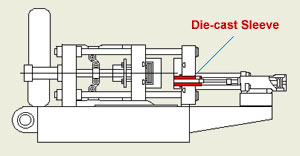

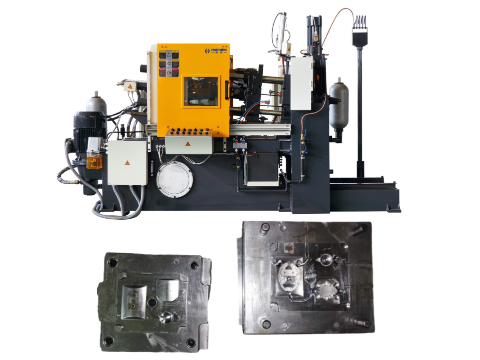

Advantages of Zinc Die Casting–Productivity Advantage

The production speed of zinc alloy die casting is very fast, and the cycle time of hot chamber die casting machines is usually about 150 times per hour, which makes mass production possible.

In addition, zinc alloy has good fluidity and can quickly fill molds, further improving production efficiency.

Advantages of Zinc Die Casting–Mould Advantage

Due to the low melting point of zinc, zinc alloy molds are not susceptible to high temperature damage, thus prolonging the service life of the mold.

This reduces the cost of tool replacement in long-term production.

Advantages of Zinc Die Casting–Application advantages

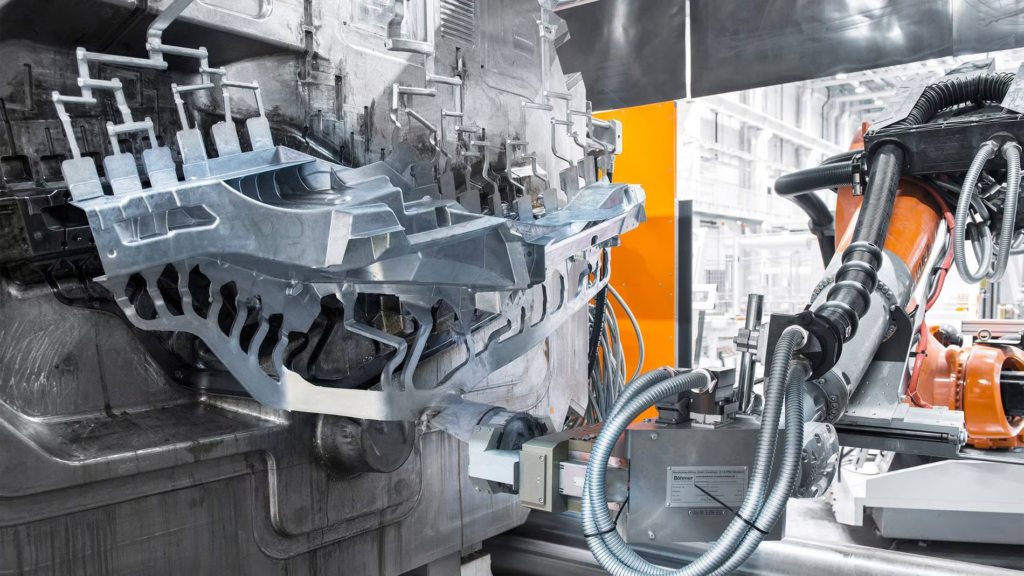

Zinc alloy die castings are commonly found in many fields such as automobiles, electronics, medical equipment, and consumer goods.

For example, they can be used to make automotive parts such as door lock housings, home appliance components, and various precision instruments.

Reduced assembly needs

Typically, zinc die castings have complete fasteners such as studs and bolts, which reduces the need for assembly operations and increases production efficiency.

Good thermal and electrical conductivity

Furthermore, zinc alloy has good thermal and electrical conductivity, making it an important application value in electronic devices.

In short, these advantages make zinc die casting an indispensable manufacturing technology for many industries.

Environmental Advantages of Zinc Die Casting

- Resource Efficient Utilization

- Low energy consumption and emissions

- Recyclability

- Waste and pollution reduction

- Compliance with environmental regulations

- Life Cycle Assessment

Resource Efficient Utilization

Zinc is a naturally occurring element that is easy to mine and recycle.

The use of zinc die casting materials can reduce dependence on other scarce resources, in line with the concept of sustainable development.

In addition, the low energy consumption of the zinc die casting process further improves the efficiency of resource utilization.

Low energy consumption and emissions

Zinc has a lower melting point (420 degrees Celsius) in the die casting process, and the use of zinc can reduce fossil fuel combustion by about 35%.

Compared to aluminum (660 degrees Celsius) and magnesium (650 degrees Celsius), thereby reducing greenhouse gas emissions.

In addition, the efficient energy consumption management of the zinc die casting process and the rapid cooling and solidification after a short period of high temperature treatment save energy.

Recyclability

Zinc die castings are recyclable materials that can be recycled and reused almost indefinitely, reducing resource waste and environmental pollution.

It is understood that the recovery rate of zinc is as high as 99%, which makes zinc die casting a significant advantage in the circular economy.

Waste and pollution reduction

Zinc die casting technology has a negligible impact on air, land and water, and consumes far less energy than comparable large-scale manufacturing processes.

In addition, zinc die casting waste and by-products can be recycled, further reducing the environmental impact of the production process.

Compliance with environmental regulations

Zinc alloys meet international chemical composition standards and meet the requirements of Waste Vehicles (ELV), Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) regulations.

The new environmentally friendly zinc alloy material is lead-free, cadmium-free, mercury-free, and meets European and American environmental protection standards.

Life Cycle Assessment

The Life Cycle Assessment (LCA) confirms the low environmental impact of zinc alloy die casting products.

By avoiding, reducing, and compensating for CO2 emissions, zinc alloy die casting offers an advanced, responsible way of production.