Cast aluminum is an aluminum alloy product obtained directly through the casting process.

Cast aluminum alloy element content is usually higher than the corresponding deformed aluminum alloy. This material has good casting properties and can produce parts with complex shapes and precise dimensions. It also has the advantages of light weight, low cost, energy saving and reduced working hours.

In this blog what is cast aluminium? We will analyse from below four aspects:

- Cast aluminium Characteristics

- Cast aluminum main alloy types

- Manufacturing process

- Environmental protection and sustainability

Casting aluminum alloys mainly include the following:

Cast aluminium Characteristics

Casting aluminium properties

- Cast aluminum alloys have good fluidity, low shrinkage, and good surface finish, making them ideal for manufacturing complex parts.

- For example, aluminum-silicon (Al-Si) alloys exhibit excellent casting characteristics due to their high silicon content (4.0% to 13.0%).

Mechanical properties

- Although die cast aluminum alloys are generally lower in strength than wrought aluminum alloys, they still have high mechanical strength and good corrosion resistance.

- For example, aluminum-copper (Al-Cu) alloys have good strength and heat resistance at high temperatures and are suitable for automotive engine parts.

Application areas

- Cast aluminum alloys wide use in aviation, automobiles, construction and other fields.

- For example, in the automotive industry, it uses to manufacture components such as cylinder heads, gearbox housings, pistons, etc.

- It can reduce the weight by about 40-60% compared to traditional cast iron parts.

Economical efficiency

Cast aluminum alloys widely use in industry due to their low cost and efficient production characteristics. For example, about 20%-30% of the world’s aluminum products are used in casting processes.

Cast aluminium main alloy types

Casting aluminum alloys mainly include the following types:

- Aluminum-silicon (Al-Si) alloy

- Aluminum-copper (Al-Cu) alloy

- Aluminum-zinc (Al-Zn) alloy

- Aluminum-magnesium (Al-Mg) alloy

Aluminum-silicon (Al-Si) alloy

This alloy has good fluidity and mechanical properties and is one of the most common types of cast aluminum alloys.

Aluminum-copper (Al-Cu) alloy

This alloy has excellent strength and heat resistance at high temperatures and is suitable for engine parts.

Aluminum-zinc (Al-Zn) alloy

This alloy has good corrosion resistance and mechanical properties and is widely used in automotive parts.

Aluminum-magnesium (Al-Mg) alloy

This alloy has high strength and good ductility and is suitable for structural parts that require high strength and light weight.

Manufacturing process

The manufacturing process of cast aluminum alloys includes low-pressure casting, sand casting, die casting and centrifugal casting.

Among them, low-pressure casting is widely used because it can produce high-quality and low-defect castings.

In addition, the application of some new technologies such as TechCastTM rare earth material system further improves the fluidity, strength and quality of castings.

Mold Preparation

- Molds are made based on the part shape. These molds can be made of steel (for precision machining), a sand-binder mix (for sand casting), or a metal mold (for die casting).

- Some processes require the creation of a “master pattern” (made of wood, metal, or plastic).

- Complex parts require the creation of a core to form the internal cavity.

Melting and Alloying

- Aluminum ingots or scrap aluminum are heated in a furnace until they reach a liquid state (approximately 660°C).

- Alloying elements (such as silicon and magnesium) are added to adjust properties.

- Impurities are removed through degassing and filtration (such as CFF filtration).

Casting

Molten aluminum is poured into the mold. The method varies depending on the process:

Gravity Casting: The mold is filled by gravity (for sand casting/permanent mold casting).

Pressure Casting

Low-Pressure Casting (20-100 psi): Air pressure is used to force the metal into the mold. This is suitable for thick-walled parts.

High-Pressure Die Casting

Rapid, high-pressure injection is used. This is suitable for complex, thin-walled parts.

Special technologies

For example, low-pressure casting of automotive wheels uses a three-stage pressurization process (20 kPa → 50 kPa → 80 kPa).

Cooling and solidification

- Natural cooling or forced cooling within the mold (e.g., air-cooled molds)

- Shrinkage compensation during the pressure maintenance phase (sprue feeding in low-pressure casting)

Post-processing

- Remove burrs, gates, and other excess material after demolding.

- Heat treatment enhances performance.

- Surface treatment (polishing, anodizing, painting, etc.).

- Machining (CNC milling/turning) to achieve final precision.

Environmental protection and sustainability

The production process of cast aluminum alloys is more environmentally friendly than traditional cast iron. For example, the recycling rate of aluminum is high, and the reuse of aluminum can significantly reduce greenhouse gas emissions.

In addition, the lightweight characteristics of aluminum help reduce vehicle fuel consumption and carbon emissions.

100% recyclable

- Aluminum can be recycled infinitely without loss of performance, and approximately 75% of the aluminum ever produced remains in circulation today.

- Recycling consumes only 5% of the energy used in primary aluminum production, significantly reducing carbon emissions.

Energy-saving Production Processes

- Continuous casting technology uses more energy than traditional processes, reduces waste by over 30%, and lowers greenhouse gas emissions.

- Green Energy Applications: Some suppliers, such as BPI, use hydropower to smelt aluminum, further reducing their carbon footprint.

Industry Emission Reduction Practices

- Companies are improving sustainability through optimized smelting, waste recycling, the use of non-toxic coatings, and renewable energy.

- The automotive industry is driving the growth of aluminum use (a threefold increase since 2000), with lightweight designs reducing vehicle fuel consumption.

Thus, cast aluminum alloys play an important role in modern industry due to their excellent casting performance, economy and environmental protection. It not only meets the manufacturing needs of complex parts, but also promotes the development of lightweight technology, and provides important material solutions for many fields such as aerospace and automobile manufacturing.

Haichen cast aluminum case

Haichen Manufacturing is an equipment used for producing high-quality cast aluminum parts.

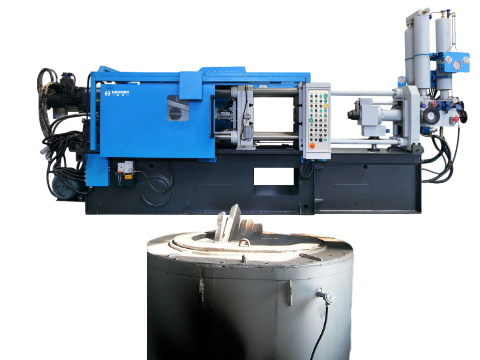

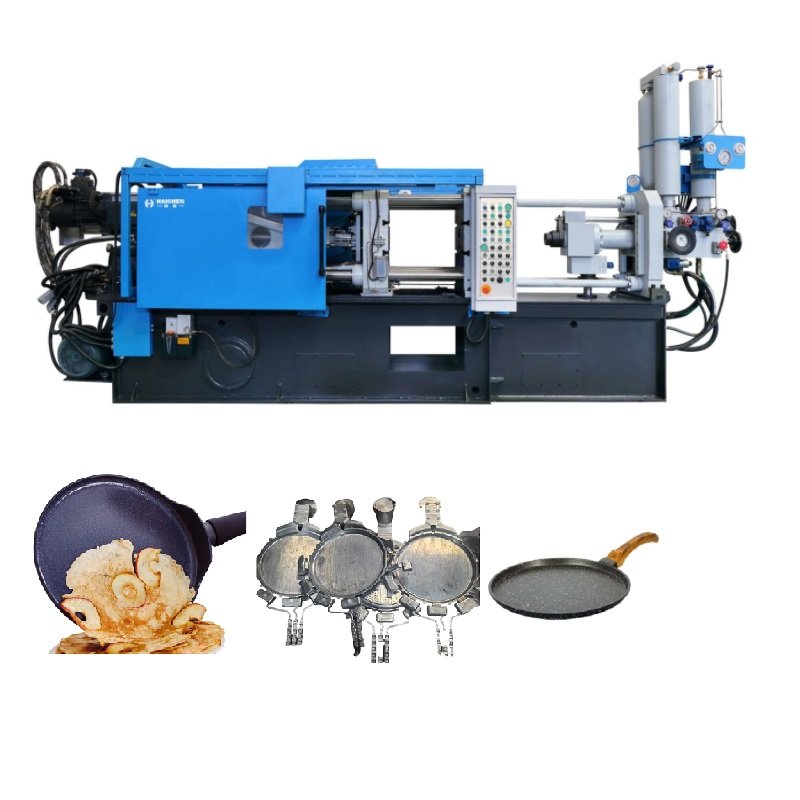

Aluminum pot handle

A kitchenware company uses Haichen cold chamber die-casting machine to produce aluminum pot handles. The pot handle produced by this process is sturdy and not easily overheated, with a comfortable shape and a smooth surface.

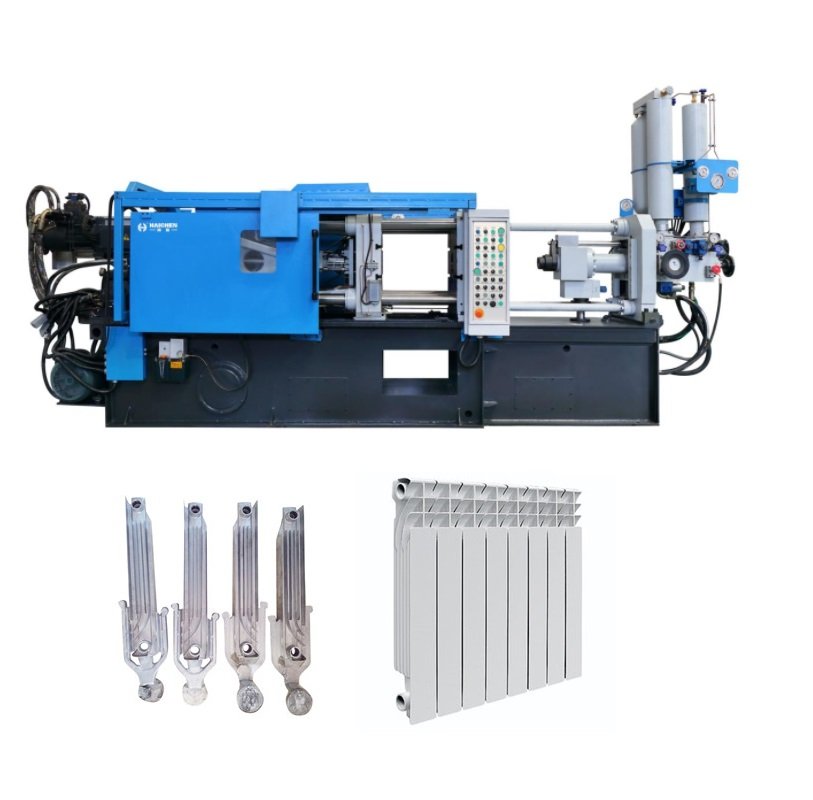

Aluminum radiator body

Haichen used to produce cast aluminium heater radiator.The cast aluminum body is lightweight, sturdy, and has excellent thermal conductivity, making the radiator efficient and durable.

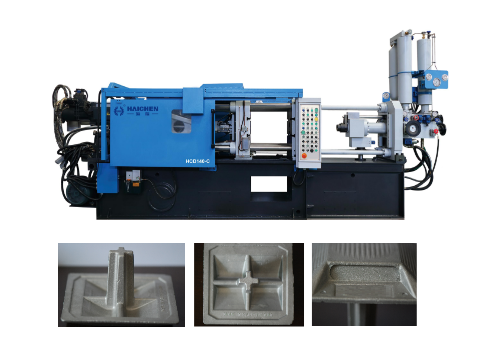

Aluminum road studs

They use Haichen’s cold chamber die casting machine for cast aluminium road studs.These road studs need to be very hard and able to withstand the effects of climate, and the cast aluminum alloy fully meets the requirements, allowing the road studs to be used for a long time on busy roads.

Casting aluminum alloy is a key material in modern manufacturing, which combines lightweight, strength, and design freedom. The die-casting process makes it suitable for large-scale and efficient production. Haichen provides reliable equipment for this, and our cold chamber die-casting machine helps manufacturers produce high-quality parts such as pot handles, radiator bodies, and road studs, which reflects the practical application and value of cast aluminum alloys in industry.

Haichen cast aluminium die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

When you have any demand, feel free to contact us.