Die casting mold making requires meeting specific part requirements, choosing appropriate materials (typically high-strength steel), accurately machining both halves, and integrating gating and venting systems for metal and coolant flow management.

Crafting a die casting mold requires creating a plan and executing the design and construction with careful attention.

Since high-quality die casting molds help in attaining uninterrupted and effective workflow, such molds help in strategic production planning.

This article will analyze the die casting mold construction processes and delineate parameters pertinent to the optimal functionality of the molds.

We will also analyze mold precision and how it determines the productivity of mold parts, production speed, and total cost of expenses in the whole production workflow.

What Is a Die Casting Mould?

A die casting mould is a tool that takes molten metal and shapes it into solid molds under high pressure. A casting die is made up of two main halves.

- Fixed Die : along with a portion of the machine’s fixed platen and a sprue and other components of the injection system, it resides in the much thicker part called the shot chamber.

- Movable Die: with ejector systems, several plates, and cores, it takes a part of the machine’s movable platen. The two dies function by close casting, then separating them to take out the solidified molten part.

Core Components :

- Mould Cavity & Cores: Define the part’s geometry (cavity for external features, cores for internal).

- Gating System: Channels molten metal into the cavity (sprue, runners, gates).

- Overflow & Venting System: Removes gases and traps impurities.

- Ejection Mechanism: Pushes solidified parts out (ejector pins, sleeves).

- Cooling/Heating Channels: Regulate mould temperature.

Working Principle: generally the die closed tightly, then filled with very high pressurized metal of around 150-1500 Mpa, and withstanding pressure machine, undergoing rapid cooling. Then, the die opens to eject the part.

Steps of Die Casting Mold Making

Before any manufacturing can happen, the production of die cast mold begins with building what is known as a mold (or a die). It is made as a construct of the end product, therefore holding great importance to its shape, size, and overall quality. The steps to construct a die casting mold include the following.

- Design and Engineering

- Material Selection

- Machining and Fabrication

- Assembly and Testing

- Finishing and Coating

Design and Engineering

The initial phase of creating a die casting mold is the design and engineering phase. This is the part of the process where use of a CAD model is critical. There is a 3D CAD geometry composed of the part, the geometry, the gates and parting lines, and the cooling channels of the die. Balance between a great number of design parameters and those of material properties and production as well as the part of highly critical issues design dimensions is intricate.

Material Selection

The cast mold is usually made of high grade steel. This steel, which is the chosen material of the cast, is selected as rest of the steel is known foe its great strength, durability and stability of temperature. The steel is also cast to enhance its hardness and also aids in preventing the wear and tear of the material. To have prolong the durability and performance of the mold is significantly important.

Machining and Fabrication

The steps involved in machining and fabrication starts with ther design and construction of a mold. The mold is created out of a steel plated block and is done in a CNC mill with advanced techniques. Precision machining guarantees that various pieces of the mold interconnected with one another perfectly. And that the mold’s cavity had the exact guideline that was needed. The czooling channels and other components of the mold are also defined during this step.

Assembly and Testing

This step is done after the components above are stitche together. This combination helps in verifying that each of the components of the mold like the two halves. And then the moving components can operate in tandem. After the small quantity of the molten metal is injected into the mold in a drop form. And then the mold is test for any cracks. Based on the adjustments that are made, the mold can be classfited upon the given standards.

Finishing and Coating

The final step that can be perform on a die casting mold. This step includes oxidation, polishing and reducing the surface flaws within the die casting mold. The die casting mold upon completion is also protect with a layer which helps the mold become more resistant corrosion and rust.

Advantages of Die casting mold making

High Precision and Consistency

With Die casting mold making, a high level of precision and consistency is maintaine throughout each part produced. And then the process can achieve and maintain a narrow tolerance to ensure dimension accuracy of every part produced.

Durability

With to a mold made of high grade steel, reinforced and designed properly. The mold will maintain its structure during rigorous high volume production activities. These types of molds will generate several thousands of parts before going through maintenance routines.

Complexity

The ability to achieve and maintain complex geometries. And then intricate details of dies with the use of a mold helps alot in the production of machine parts and other various consumer electronics.

Common Problems and Practical Suggestions

| Problem | Suggestion |

| Improper gate design leading to cold welding | Reduce gate velocity through CAE flow field simulation, appropriately increase overflow area, or use a split gate. |

| Mold thermal cracks | Improve cooling balance, use heat balance channels, and perform heat treatment (quenching and tempering or nitriding) to improve heat resistance. |

| Short mold life | Check heat treatment process and surface hardening (nitriding/carburizing) for compliance, and replace worn parts promptly. |

| Large dimensional deviation | Use high-precision CNC machining, strict assembly positioning, and regular calibration of measuring instruments. |

HAICHEN Mold Solution Practices

Case Study: 280X70 Aluminum Deep Fry Pan Mold

HAICHEN successfully developed a 280X70 aluminum deep fry pan die-casting mold for a renowned cookware manufacturer with the following technical specifications:

- Product weight: 1.0kg

- Dimensions: Top diameter 28cm, bottom diameter 25cm, height 70mm

- Wall thickness requirements: Bottom 4.0mm, side wall 2.8mm

- Mold size: 280X70

Technical Challenges and Solutions:

- Deep cavity filling challenge: Implemented HAICHEN’s patented multi-point sequential valve control system to ensure smooth molten metal filling in deep cavities

- Thick-thin transition control: Established differentiated cooling channels in transition areas through precise thermal balance analysis

- Surface quality requirements: Applied mirror polishing process to mold cavity, achieving surface roughness of Ra0.2μm

Production Performance:

- Cycle time: 45 seconds per part

- Yield rate: 98.5%

- Mold life: Expected 300,000 shots

- Daily production: 1,500 pieces

Our solution covered key steps:

During design, we used flow and thermal simulation to optimize the gating and cooling layout. We selected high-grade tool steel and applied surface hardening. Precision 5-axis machining and mirror polishing achieved high accuracy and a surface finish of Ra0.2μm. After rigorous testing, the mold achieved a stable 45-second cycle time, a mass production yield of 98.5%, and an expected lifespan exceeding 300,000 shots, fully meeting the customer’s high-volume quality requirements.

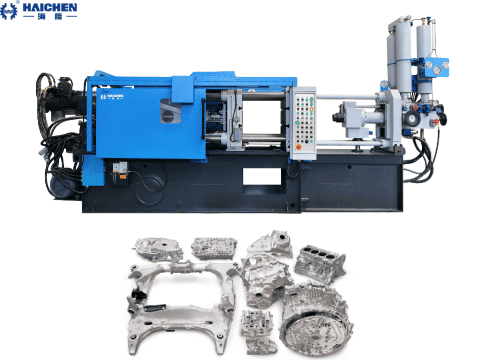

HAICHEN:Die Casting Machine Manufacturer

HAICHEN uses sophisticated technology to design and manufacture die casting machines that meet the highest requirements of heavy industrial work. We offer a variety of die casting machines, including both cold chamber and hot chamber, to meet your specific production targets. HAICHEN also offers extensive para-sales services to protect your investment, including training, technical support, spare part provision, and thorough after-sales assistance.

The steps discussed above offer a guideline that can assist any manufacturing in producing high grade die casting mold for the purpose of mass and precise part production.