Die Cast Cookware Benefits have easy to clean, uniform heating and heat retention, high durability, versatility and so on.Die-cast aluminum cookware has a variety of advantages, and here is a detailed description of its main advantages:

- Superior Product Performance and Quality

- Manufacturing Efficiency and Design Flexibility

- Economic and Market Advantages for Manufacturers

- HAICHEN’s Role in Realizing Cookware Manufacturing Benefits

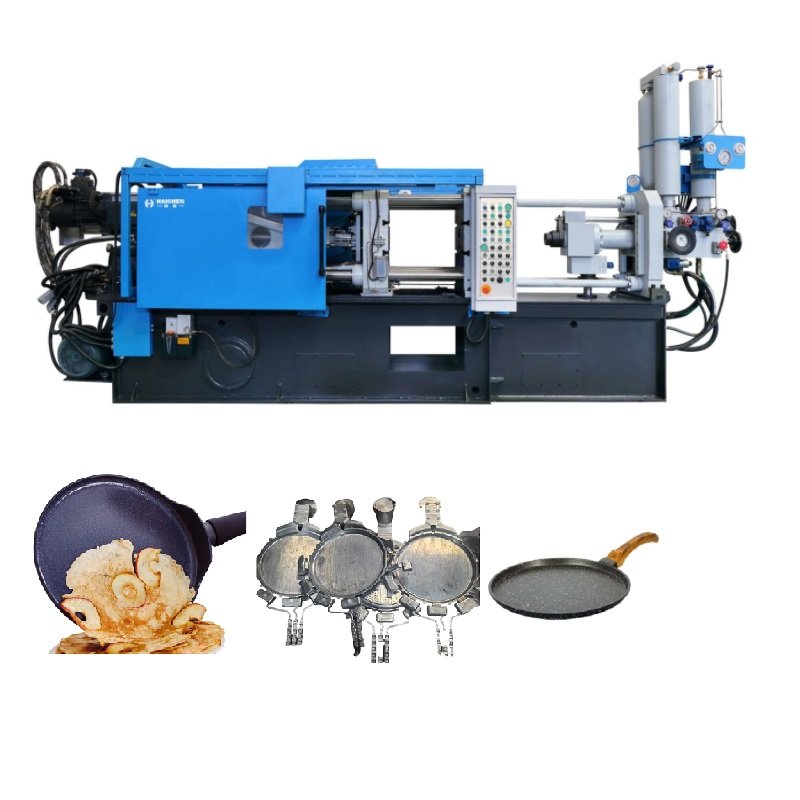

Die cast cookware is made by injecting molten aluminum into a steel mold under high pressure. This article will explain the key advantages of this production method. We will discuss the superior performance of the final product, the efficiency of the manufacturing process, and the economic benefits for makers. Finally, we will show how HAICHEN’s machines enable these benefits for manufacturers.

Superior Product Performance and Quality

The die casting process gives cookware excellent functional properties.

- Exceptional Heat Distribution and Response

- High Structural Strength and Durability

- Consistent Quality and Precise Dimensions

Exceptional Heat Distribution and Response

The cast aluminum body has uniform density and no gaps. Heat spreads quickly and evenly across the entire cooking surface. This prevents hot spots and ensures food cooks uniformly.

High Structural Strength and Durability

High-pressure filling creates a very dense metal structure. This makes the cookware robust and resistant to denting or warping from thermal shock, guaranteeing a long service life.

Consistent Quality and Precise Dimensions

Every piece from the same mold is identical. This gives perfect consistency in weight, wall thickness, and shape, which is crucial for both performance and stacking in storage.

Manufacturing Efficiency and Design Flexibility

The process offers significant advantages for production.

- High-Speed, High-Volume Production Capability

- Ability to Create Complex, Integrated Shapes

- Excellent Surface Finish for Minimal Post-Processing

High-Speed, High-Volume Production Capability

Die casting cycles are very fast, often taking less than a minute per part. This allows for the cost-effective mass production of items like pots, pans, and lids.

Ability to Create Complex, Integrated Shapes

The process can form intricate handles, spouts, and reinforcement ribs in a single step. It can also cast-in metal inserts for handles, eliminating the need for later riveting.

Excellent Surface Finish for Minimal Post-Processing

The surface straight from the mold is very smooth. This reduces the time and cost needed for polishing and finishing before applying non-stick coatings or other treatments.

Economic and Market Advantages for Manufacturers

These benefits translate directly to a stronger business position.

- Reduced Material Waste and Lower Unit Cost

- Simplified Assembly and Lower Labor Costs

- Enhanced Brand Value through Premium Product Quality

Reduced Material Waste and Lower Unit Cost

The near-net-shape casting minimizes excess material. Combined with fast cycle times, this results in a very competitive cost per unit for large production runs.

Simplified Assembly and Lower Labor Costs

By integrating features like handles, the number of separate parts is reduced. This simplifies the assembly line, cuts labor time, and lowers overall production costs.

Enhanced Brand Value through Premium Product Quality

Superior heat distribution, durability, and consistent finish are tangible quality markers that consumers value. This allows brands to command a higher price point and build customer loyalty.

HAICHEN’s Role in Realizing Cookware Manufacturing Benefits

HAICHEN provides the reliable, high-performance machinery needed for top-quality die cast cookware production.

- Case: Enabling a Manufacturer’s Product Line Upgrade

- The HAICHEN Advantage: Precision and Stability for Mass Production

Case: Enabling a Manufacturer’s Product Line Upgrade

A cookware company in Istanbul wanted to launch a new line of premium aluminum fry pans with an integrated handle design. Their old equipment could not achieve the required thin wall thickness without defects.

HAICHEN supplied a 500-ton cold chamber machine with precise injection control. This machine filled the complex mold perfectly every time, producing pans with consistent 2.5mm thin walls, excellent surface finish, and high structural integrity.

The success of this line significantly boosted the manufacturer’s market share.

The HAICHEN Advantage: Precision and Stability for Mass Production

For cookware, aesthetic consistency is as important as performance. HAICHEN machines deliver this through stable clamping and repeatable injection profiles. Our robust construction ensures this precision is maintained over millions of cycles, which is essential for profitable high-volume cookware manufacturing. We provide the dependable technology that turns design advantages into commercial success.

The benefits of die cast cookware are clear: superior cooking performance, efficient high-volume production, and strong economic value. For manufacturers, this method enables the creation of premium, competitive products. Success depends on using precise and reliable die casting technology. As demonstrated by HAICHEN, partnering with an expert machine builder provides the essential capability to consistently achieve these benefits, ensuring quality and profitability in the cookware market.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

When you have any demand, feel free to contact us.